Two-dimensional ceramic material catalyst rich in unsaturated coordinations, and preparation method and application thereof

A technology of ceramic materials and catalysts, which is applied in the field of two-dimensional ceramic material catalysts rich in unsaturated coordination and its preparation and application. It can solve problems such as harsh operating conditions, high toxicity of hydrofluoric acid, and the impact of MXene applications. It meets the conditions Gentle, short preparation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

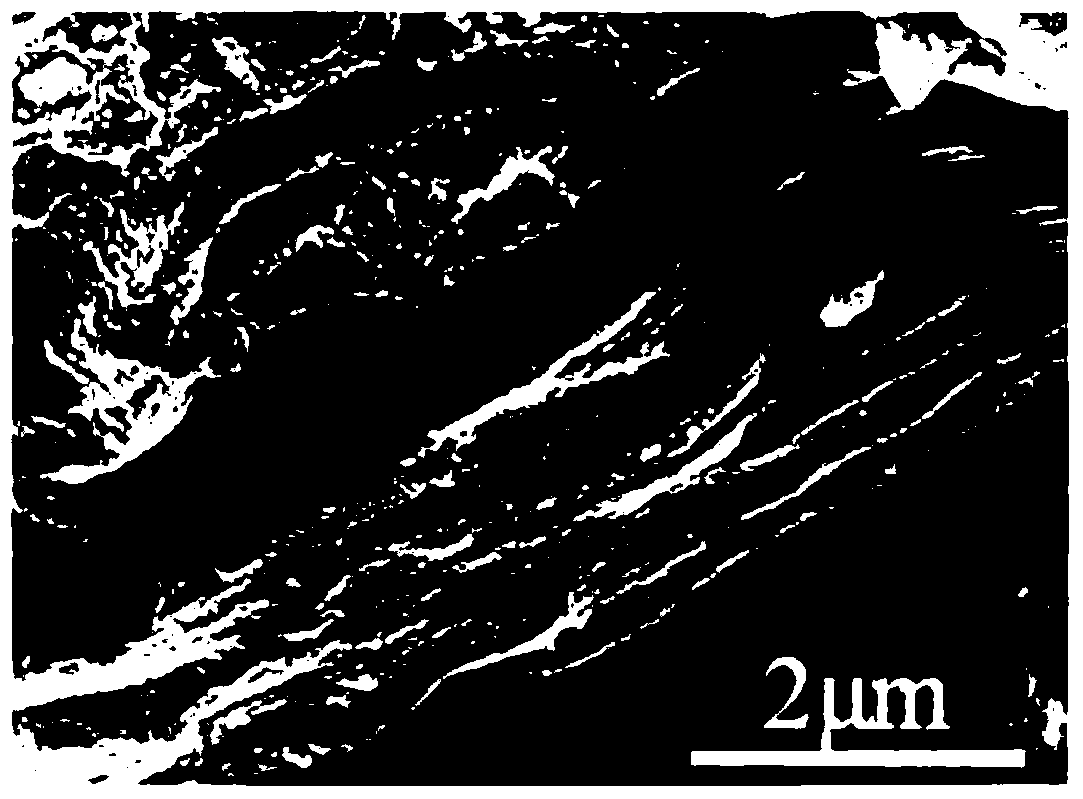

[0024] At room temperature, 3.04g Ti 3 AlC 2 Put it into 30mL hydrofluoric acid solution, the concentration of hydrofluoric acid solution is 30wt%, after magnetic stirring for 12h, centrifuge, the obtained solid is washed 5 times with deionized water, and dried to obtain nano-scale Ti which is rich in unsaturated coordination. 3 Al x C 2 (x=0~1) catalyst, gained Ti 3 Al x C 2 (x=0~1) The SEM picture of the catalyst is as follows Figure 1a with Figure 1b shown, from Figure 1a with Figure 1b It can be seen that the catalyst presents a two-dimensional layered stacking structure, and there are a large number of nanoscale gaps between the layers, which makes it easier to adsorb F, thereby breaking the C-F bond, and catalyzing the reaction of fluorine-containing alkanes to HF to prepare fluorine-containing olefins.

[0025] The nanoscale Ti rich in unsaturated coordination prepared above 3 Al x C 2 (x=0~1) The catalyst is used to catalyze the cracking of 1,1-difluoroet...

Embodiment 2

[0029] At room temperature, dilute concentrated hydrochloric acid with water to a concentration of 9 mol / L to form solution A. Measure 50mL solution A, add 5gLiF, stir magnetically for 10min, add 5g Ti 3 AlC 2 , reacted at 55°C for 12 hours, centrifuged, and the obtained solid was washed 5 times with deionized water and dried to obtain nano-scale Ti rich in unsaturated coordination. 3 Al x C 2 (x=0~1) Catalyst. Obtained Ti 3 Al x C 2 (x=0~1) The SEM picture of the catalyst is as follows figure 2 shown, from figure 2 It can be seen that the catalyst presents a two-dimensional layered stacking structure, and there are a large number of nanoscale gaps between the layers, which makes it easier to adsorb F, thereby breaking the C-F bond, and catalyzing the reaction of fluorine-containing alkanes to HF to prepare fluorine-containing olefins. Obtained Ti 3 Al x C 2 (x=0~1) The XRD pattern of the catalyst is as follows image 3 shown, according to image 3 It can be se...

Embodiment 3

[0034] oxalic acid and Ti 3 AlC 2 (Ti 3 AlC 2 Quality is 3.01g) is mixed according to the molar ratio of 2:1 and placed in the ball mill jar, ball milled 2h with the rotating speed of 300r / min, the mixture after ball milling is put into tube furnace and carries out high-temperature roasting (high-temperature roasting process is: under nitrogen Under atmosphere, the temperature was raised from room temperature to 350 °C at 3 °C / min, followed by 3 hours of heat preservation, and then naturally cooled to room temperature), that is, nano-scale Ti rich in unsaturated coordination was obtained. 3 Al x C 2 (x=0~1) Catalyst.

[0035] The nanoscale Ti rich in unsaturated coordination prepared above 3 Al x C 2 (x=0~1) The catalyst is used to catalyze the cracking of 1,1-difluoroethane (HFC-152a) to prepare vinyl fluoride, and the reaction formula is as follows:

[0036]

[0037] The reaction conditions are: the catalyst is loaded into the fixed bed reactor, the catalyst load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com