A kind of antibacterial formaldehyde removal catalytic material and its preparation method and application

A catalytic material and formaldehyde technology, applied in the field of antibacterial formaldehyde removal catalytic materials and its preparation, can solve the problems of unsatisfactory effect and safety of formaldehyde removal coatings, achieve long-term and complete removal of formaldehyde, good prospects, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

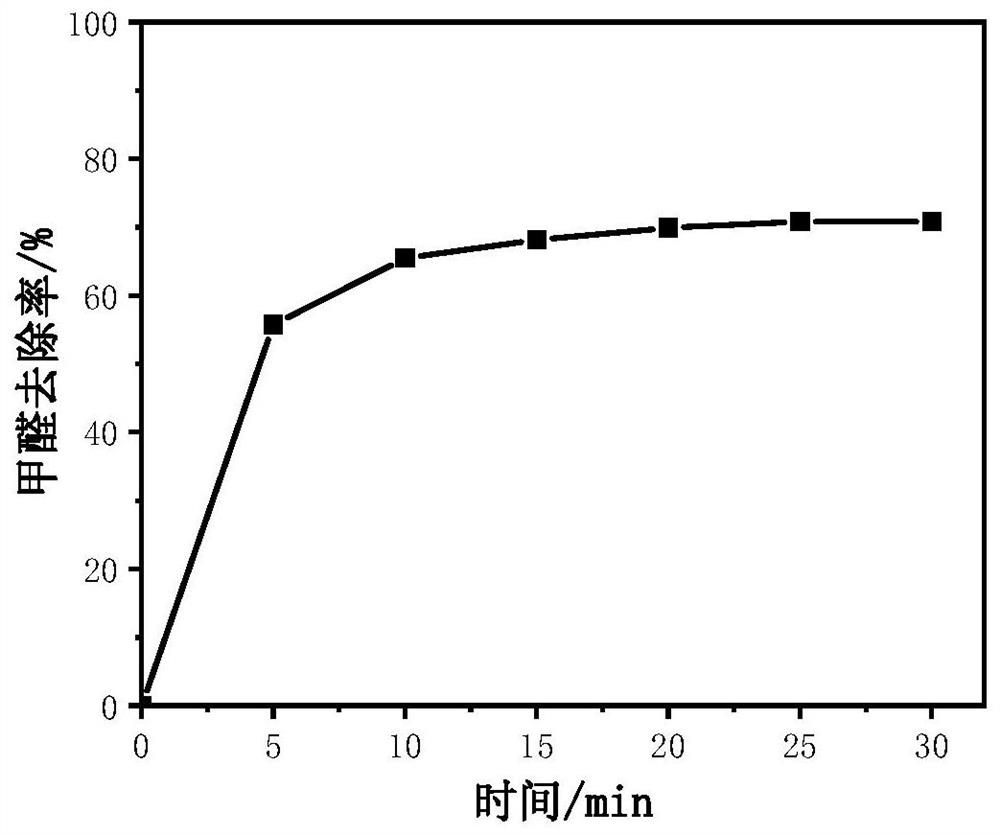

Embodiment 1

[0032] (1) Weigh 3.0kg of potassium permanganate, 3.0kg of ferric chloride, 4.0kg of ammonium oxalate, and 3.0kg of silver nitrate in a reaction kettle, and add 100L of distilled water into the reaction kettle, stir and mix until evenly mixed. Heat and stir in water at 100°C for 9 hours, and cool to room temperature naturally after the reaction. Soak and stir the modified material after reaction with pure water for 30 minutes, and pour off the upper layer of water after the material slowly settles. Put the cleaned material into an oven and dry it at 70°C to obtain an antibacterial and formaldehyde-removing catalytic material.

[0033] (2) Take 0.4 kg of titanium dioxide and put it into a grinder, grind it for 20 minutes, and sieve it to obtain powder. Then take the prepared 1.2kg antibacterial and formaldehyde-removing catalytic material, 2.0kg styrene-acrylic emulsion and 0.28kg water to the mixer A and stir for 20 minutes, after mixing evenly, stir for 20 minutes to obtain ...

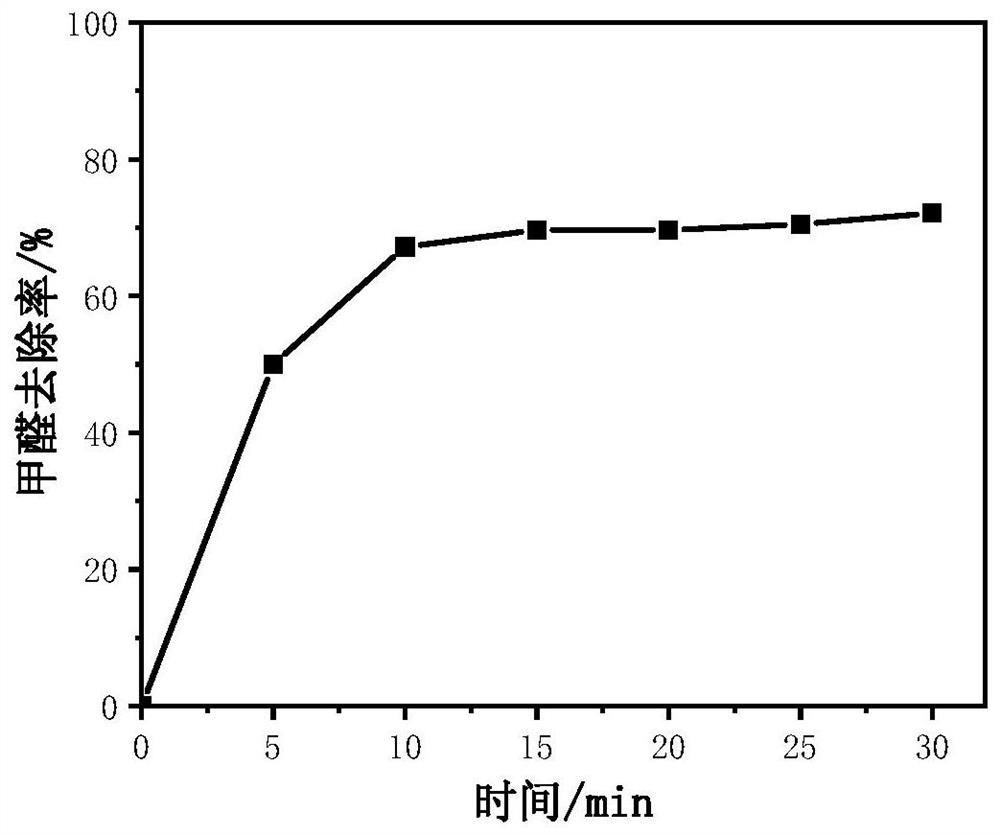

Embodiment 2

[0036] (1) Weigh 3.0kg of potassium permanganate, 3.0kg of ferric chloride, 4.0kg of ammonium oxalate, and 3.0kg of silver nitrate in a reaction kettle, and add 100L of distilled water into the reaction kettle, stir and mix until evenly mixed. Heat and stir in water at 100°C for 9 hours, and cool to room temperature naturally after the reaction. Soak and stir the modified material after reaction with pure water for 30 minutes, and pour off the upper layer of water after the material slowly settles. Put the cleaned material into an oven and dry it at 70°C to obtain an antibacterial and formaldehyde-removing catalytic material.

[0037](2) Take 1.0 kg of titanium dioxide and put it into a grinder, grind it for 20 minutes, and sieve it to obtain a powder. Then take the prepared 3.0kg antibacterial and formaldehyde-removing catalytic material, 5.0kg styrene-acrylic emulsion and 0.7kg water to the mixer A and stir for 20 minutes, after mixing evenly, stir for 20 minutes to obtain ...

Embodiment 3

[0040] (1) Weigh 3.0kg of potassium permanganate, 3.0kg of ferric chloride, 4.0kg of ammonium oxalate, and 3.0kg of silver nitrate in a reaction kettle, and add 100L of distilled water into the reaction kettle, stir and mix until evenly mixed. Heat and stir in water at 100°C for 9 hours, and cool to room temperature naturally after the reaction. Soak and stir the modified material after reaction with pure water for 30 minutes, and pour off the upper layer of water after the material slowly settles. Put the cleaned material into an oven and dry it at 70°C to obtain an antibacterial and formaldehyde-removing catalytic material.

[0041] (2) Take 0.4 kg of titanium dioxide and put it into a grinder, grind it for 20 minutes, and sieve it to obtain powder. Then take the prepared 3.0kg antibacterial and formaldehyde-removing catalytic material, 2.0kg styrene-acrylic emulsion and 0.7kg water to the mixer A and stir for 20 minutes. After mixing evenly, stir for 20 minutes to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com