Method and device for desulfurization of high-temperature flue gas through forced grinding and on-line decomposition CaCO3

A high-temperature flue gas and flue gas technology, applied in the field of flue gas desulfurization, can solve the problems of not being widely used in commercial applications, easy formation of wet ash and pulp lumps, and high capital investment costs, so as to improve the utilization rate of calcium base, increase the The effect of large residence time, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

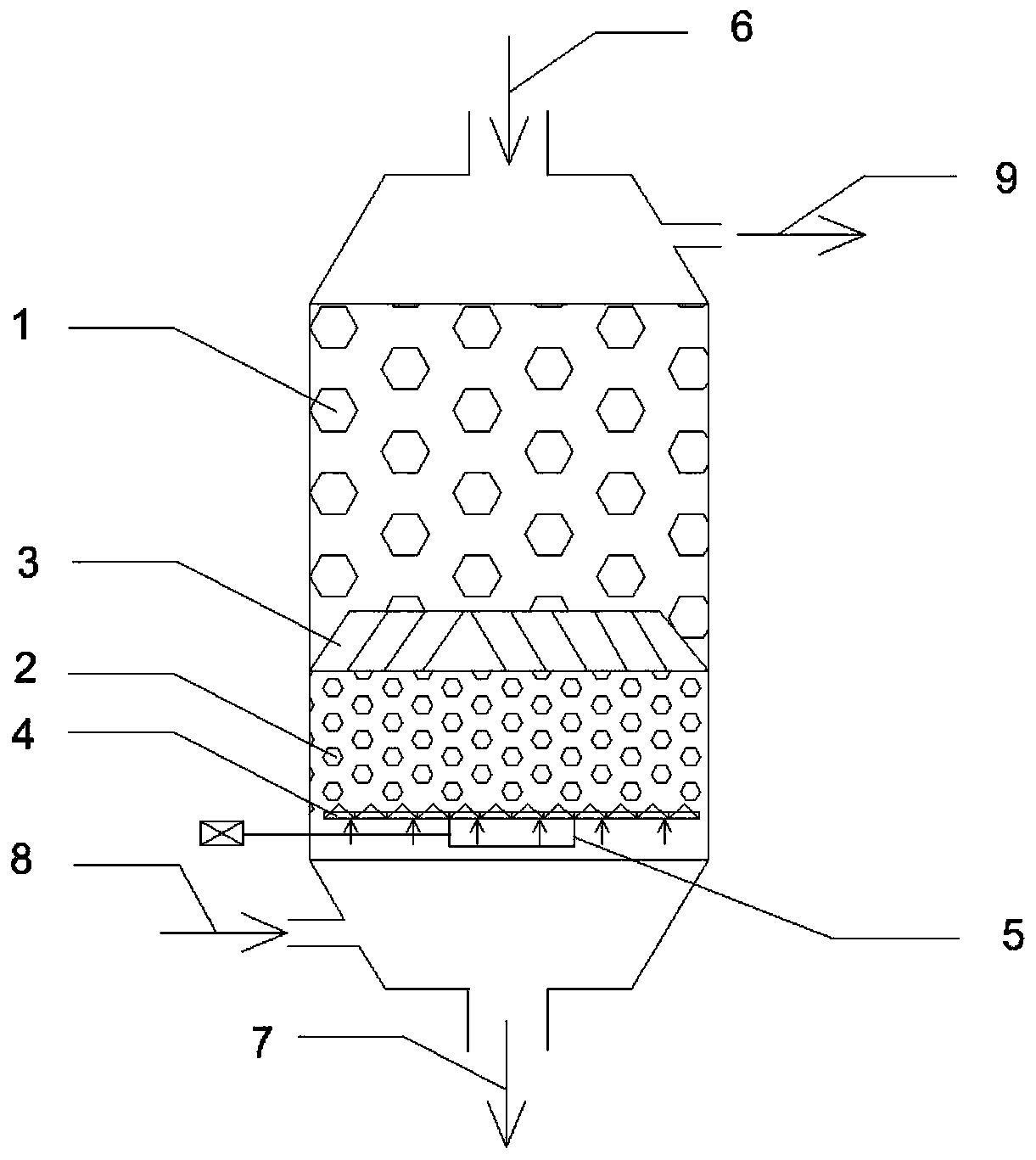

[0024] The simulated flue gas temperature is 700°C, SO 2 Concentration 1000mg / Nm 3 , flue gas volume 400Nm 3 / h, the simulated flue gas enters the desulfurization tower through the flue gas inlet 8, CaCO 3 The height of decomposition zone 1 is 1.0m, the height of desulfurization section 2 is 0.5m, the particle size of desulfurizer is 0.1mm, the flow rate of flue gas is 3.8m / s, and the flue gas after desulfurization treatment flows out from flue gas outlet 9. The calculated desulfurization efficiency is 90.1%.

Embodiment 2

[0026] The simulated flue gas temperature is 700°C, SO 2 Concentration 1000mg / Nm 3 , flue gas volume 400Nm 3 / h, the simulated flue gas enters the desulfurization tower through the flue gas inlet 8, CaCO 3 The height of decomposition zone 1 is 1.2m, the height of desulfurization section 2 is 1.0m, the particle size of desulfurizer is 0.05mm, the flow rate of flue gas is 3.8m / s, and the flue gas after desulfurization treatment flows out from flue gas outlet 9. The calculated desulfurization efficiency is 92.3%.

Embodiment 3

[0028] Simulated flue gas temperature 900°C, SO 2 Concentration 1000mg / Nm 3 , flue gas volume 400Nm 3 / h, the simulated flue gas enters the desulfurization tower through the flue gas inlet 8, CaCO 3 The height of decomposition zone 1 is 1.0m, the height of desulfurization section 2 is 0.5m, the particle size of desulfurizer is 0.1mm, the flow rate of flue gas is 3.8m / s, and the flue gas after desulfurization treatment flows out from flue gas outlet 9. The calculated desulfurization efficiency is 92.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com