Gallium oxide vertical structure semiconductor electronic device and manufacturing method thereof

A vertical structure and electronic device technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as large breakdown voltage, lower production costs, buffer layer leakage, etc., achieve large saturation current, simple structure , the effect of high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

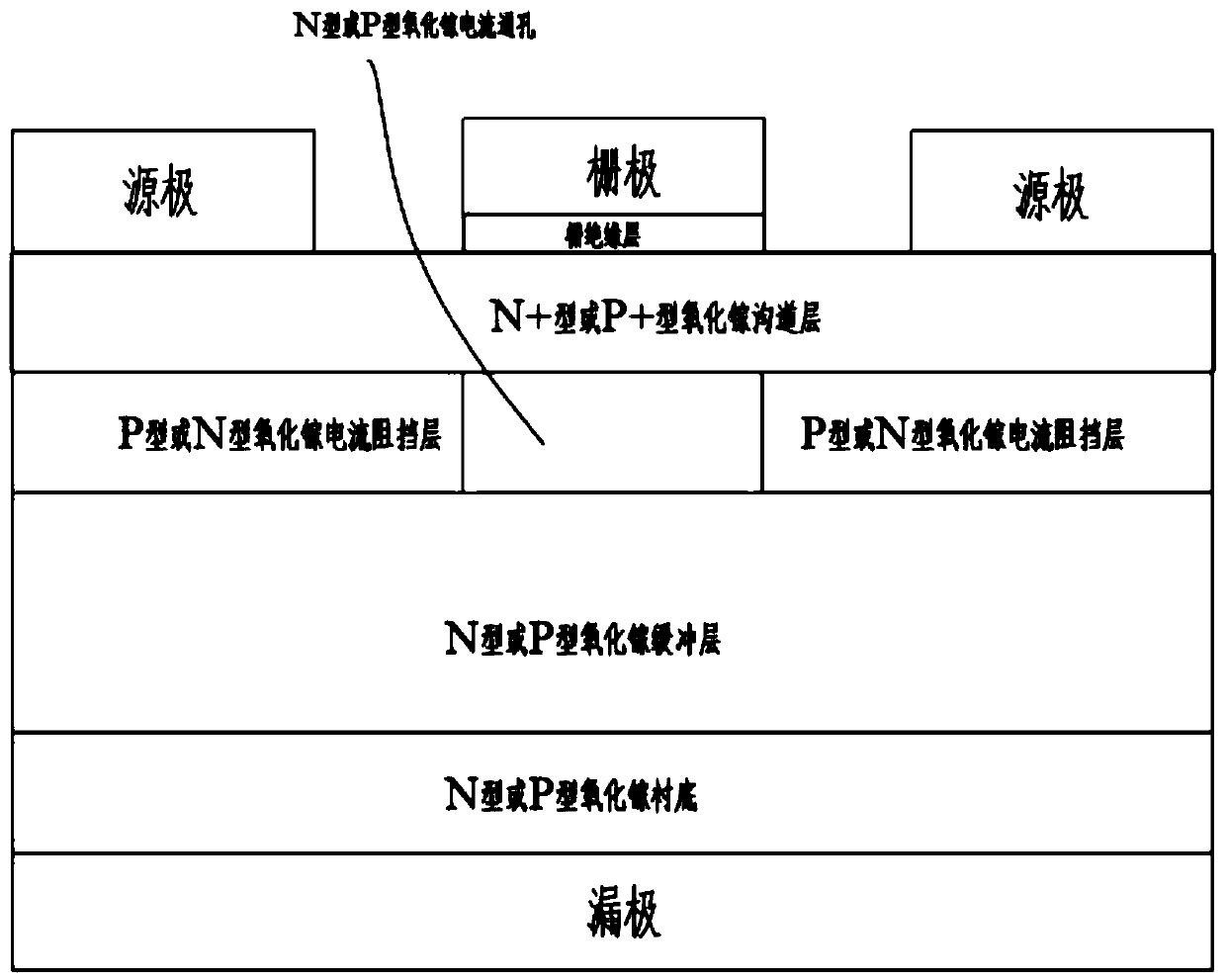

[0019] An embodiment of the present invention provides a semiconductor electronic device with a gallium oxide vertical structure, which includes a buffer layer, a current blocking layer, and a channel layer arranged in sequence, and the current blocking layer is also distributed with current formed by ion implantation. A through hole, the channel layer is provided with a source and a gate, the buffer layer is connected to the drain, the drain is arranged opposite to the current blocking layer, and the current through hole is located under the gate, so The channel layer is electrically connected to the buffer layer through the current via hole.

[0020] Further, when the device is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com