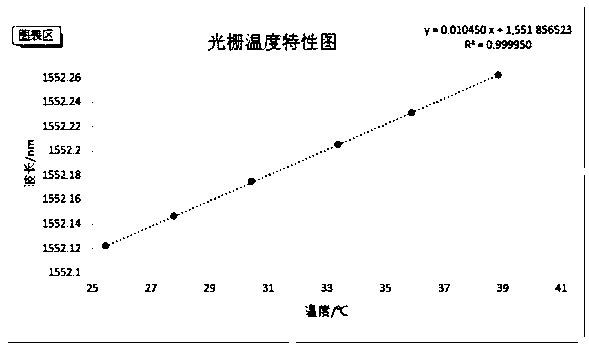

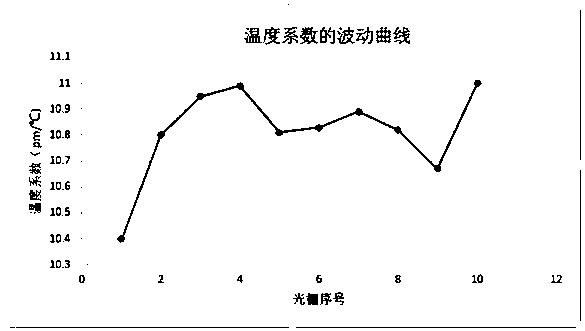

Ultra-weak fiber grating optical cable used for water temperature monitoring

A technology of weak fiber gratings and fiber grating arrays, applied in the field of ultra-weak fiber grating optical cables, can solve the problems of complex structure, poor waterproofness, and low temperature measurement accuracy of temperature-sensing optical cables, and achieve good application prospects, good waterproofness, and suppression of accumulation distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

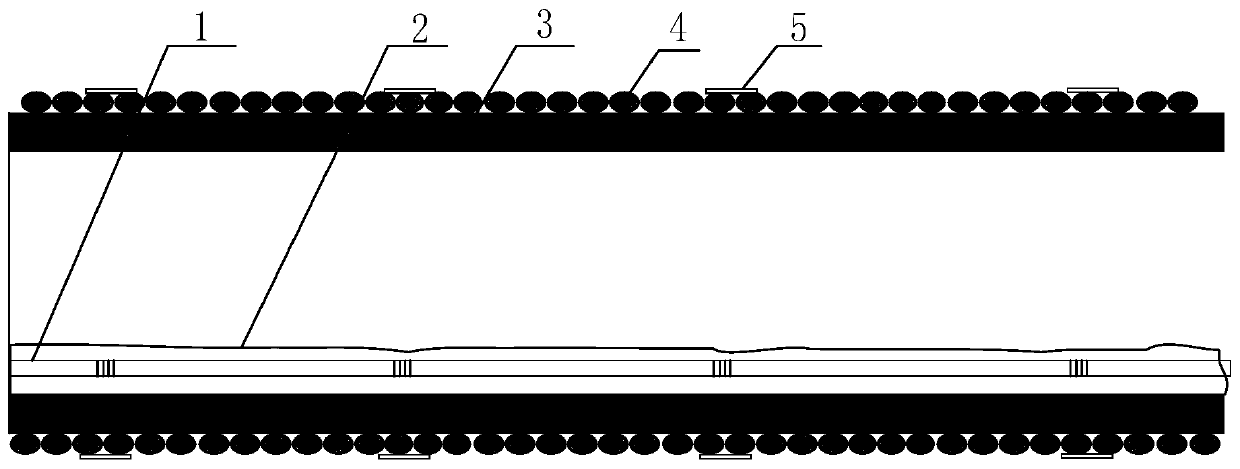

[0039] An ultra-weak fiber grating optical cable applied to water temperature monitoring, including:

[0040] The ultra-weak fiber grating array 1 in the center;

[0041] A small amount of grease layer 2 uniformly covering the ultra-weak fiber grating array 1 along the axial direction;

[0042] Wrap the metal tube 3 surrounding the ultra-weak fiber grating array 1, the ointment layer 2;

[0043] A reinforcing member 4 that is twisted around the metal tube 3 in a spiral form;

[0044] The sensor mark 5 is coated on the outside of the reinforcement 4.

[0045] The ultra-weak fiber grating array 1 includes a low elastic modulus single-layer coating 8 with a thickness of less than 30 um, preferably modified acrylate, and no obvious glass transition temperature at -25°C to 100°C. Traditional fiber grating adopts double-layer coating. The temperature nonlinearity of the coating material affects the temperature-sensing characteristics of the grating. The single-layer coating layer 8 with low e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com