Method for directly growing two-dimensional hexagonal boron nitride on dielectric substrate

A two-dimensional hexagonal and boron nitride technology, applied in the field of material science, can solve the problems of h-BN nucleation difficulties, limited crystal quality, uneven nucleation, etc., achieve good controllability, improve crystal quality, and avoid transfer The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

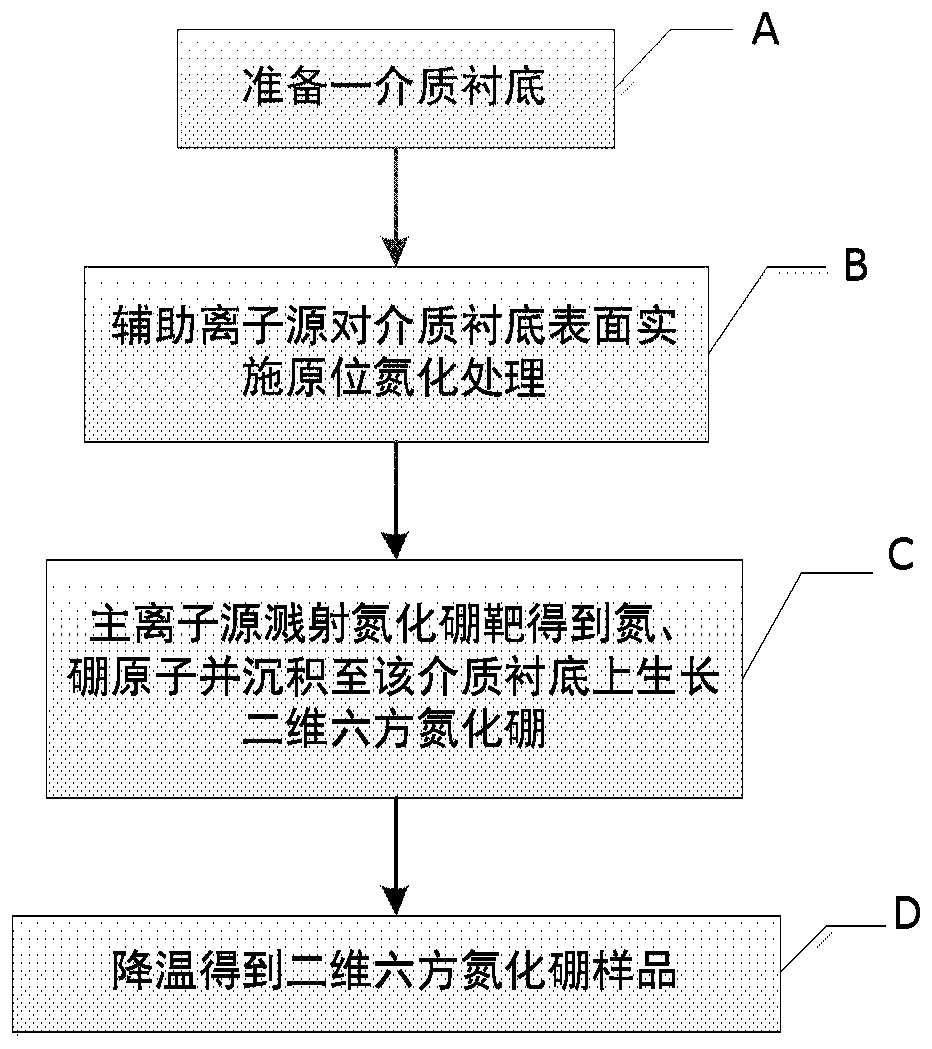

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

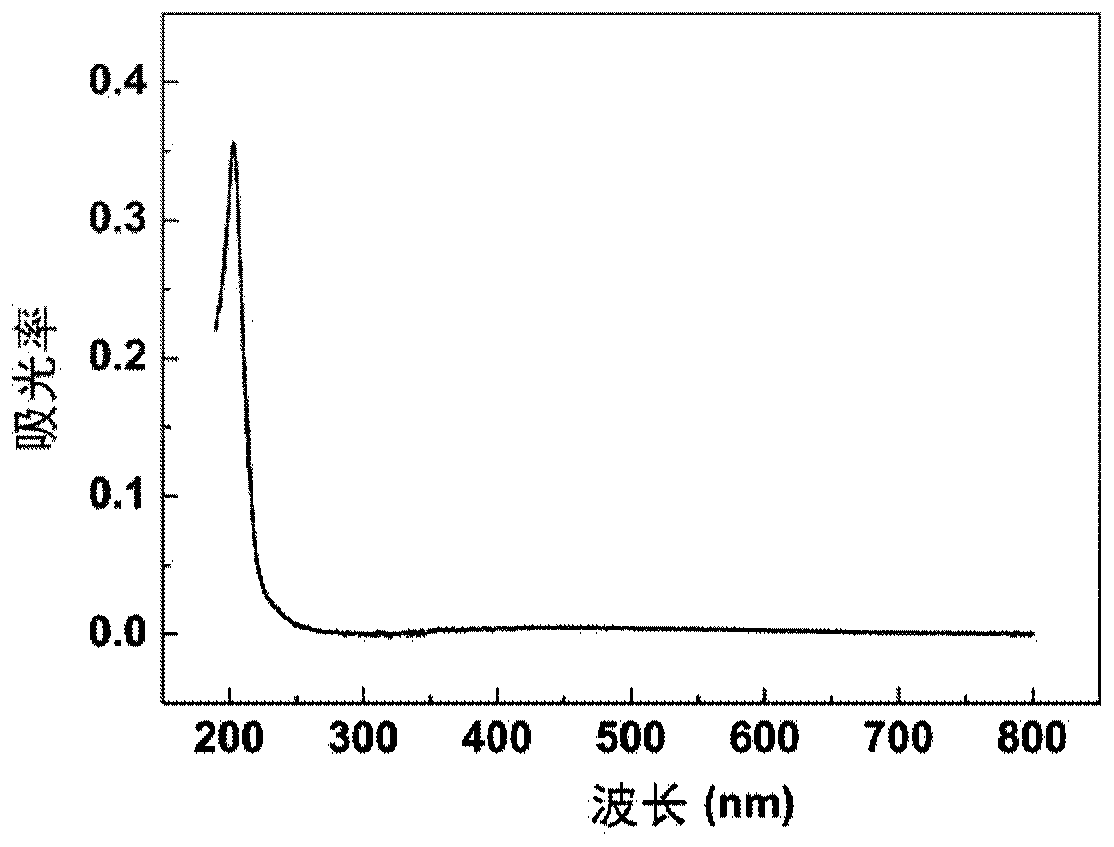

[0038] The invention adopts ion beam assisted deposition technology to directly grow two-dimensional h-BN on the dielectric substrate, promotes the nucleation of h-BN on the dielectric substrate through in-situ nitriding treatment of the substrate surface by the ion beam, and simultaneously uses nitrogen ions Beam sputtering grows h-BN, provides sufficient nitrogen source, improves the crystal quality of h-BN film, and grows h-BN two-dimensional atomic crystal directly on the dielectric substrate.

[0039] It should be noted that, in the drawings or descriptions of the specification, similar or identical parts all use the same figure numbers. Implementations not shown or described in the accompanying drawings are forms kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com