Compound polymerized acrylate rubber and preparation method thereof

A technology of polymethyl methacrylate and acrylate, applied in the rubber field, can solve the problems of limiting the application field of acrylic rubber, insufficient hardness, etc., and achieve the effects of not easy separation, less auxiliary materials, and improved toughness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

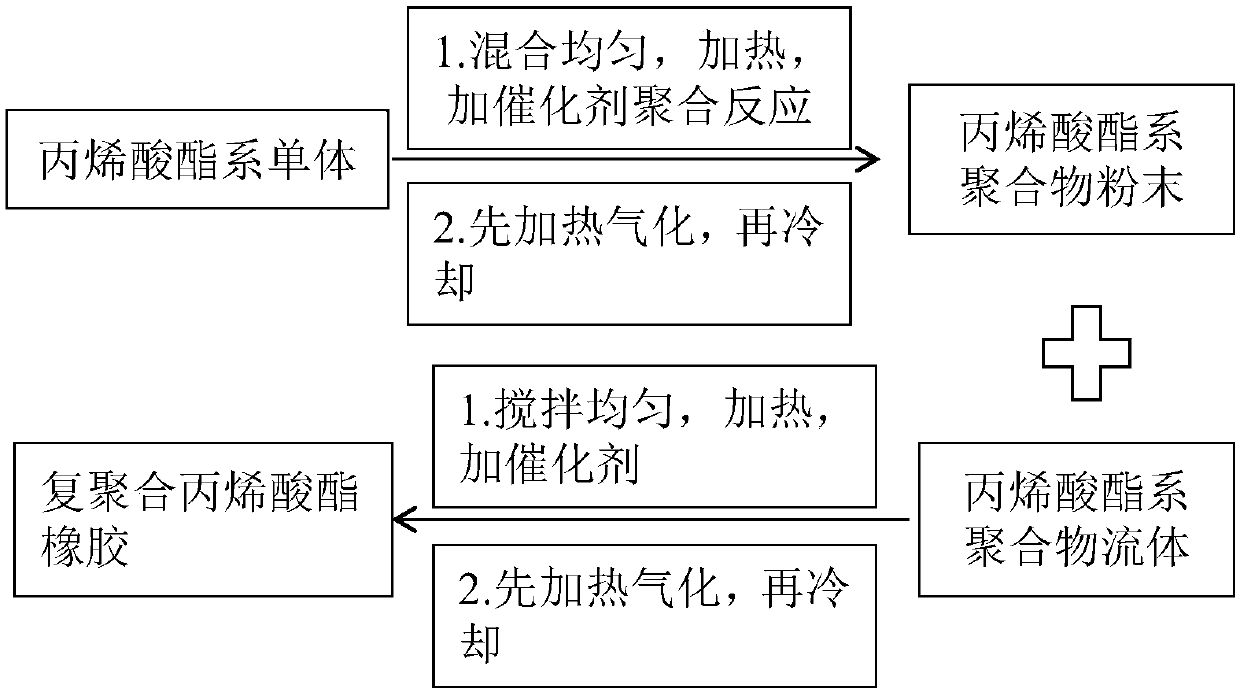

Method used

Image

Examples

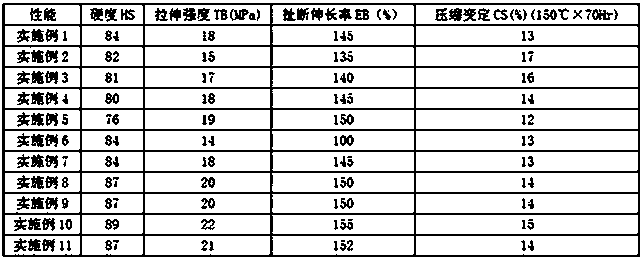

Embodiment 1

[0047] Repolymerized acrylate rubber, comprising a polymer core formed by polymerizing acrylate-based monomers and polymethyl methacrylate coated on the surface of the core; wherein the acrylate-based monomer is ethyl acrylate or butyl acrylate One or two of the combination, the mass fraction of the acrylate monomer accounts for 65% of the combined weight of the acrylate monomer and the polymethyl methacrylate core.

Embodiment 2

[0049] Repolymerized acrylate rubber, the difference between Example 2 and Example 1 is that the mass fraction of the acrylate-based monomer accounts for 50% of the combined weight of the acrylate-based monomer and the polymethyl methacrylate core.

Embodiment 3

[0051] Repolymerized acrylate rubber, the difference between Example 3 and Example 1 is that the mass fraction of the acrylate-based monomer accounts for 60% of the combined weight of the acrylate-based monomer and the polymethyl methacrylate core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com