A kind of technological method of utilizing pentaerythritol tetraacrylate waste water to prepare polyester antistatic agent

A technology of pentaerythritol tetraacrylate and antistatic agent, which is applied in fiber treatment, textile and papermaking, fiber type, etc., can solve the problems of high cost of waste liquid treatment, aggravating the operation burden of manufacturers, and high treatment cost, so as to save waste. Liquid treatment input, obvious antistatic effect, simple preparation method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0034] One embodiment of the present invention provides a kind of process that utilizes pentaerythritol tetraacrylate wastewater to prepare polyester antistatic agent, comprising steps:

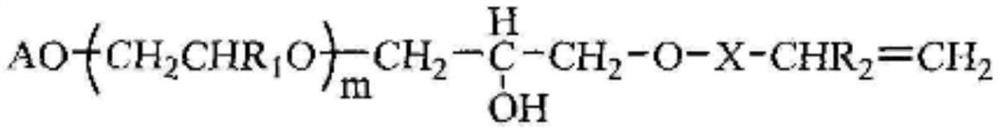

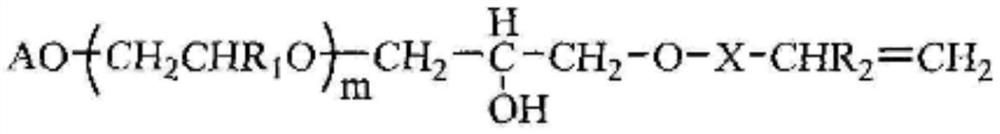

[0035] Put the waste liquid containing acrylic acid and its acrylate, the alkoxy polyether with double bond at the end and water into the reactor and mix to obtain the mixed liquid;

[0036] Using nitrogen to replace the gas phase part in the above reactor, heating the mixed solution to 75°C-85°C;

[0037] The initiator sodium persulfate aqueous solution is regularly added to the reactor several times to carry out free radical polymerization;

[0038] cooling the reactor;

[0039] Add aqueous sodium hydroxide solution and pure water to the reactor, adjust the pH value and concentration of the reaction solution, and obtain an antistatic agent for polyester fabrics;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com