Advanced treatment system and method for textile printing and dyeing sewage

A technology for textile printing and dyeing and advanced treatment, which is used in textile industry wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc. High problems, to achieve the effect of reducing aeration energy consumption, good removal effect and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Sewage:

[0061] A textile printing and dyeing park directly receives the effluent after pretreatment of the enterprise, the characteristic pollutant indicators: COD: 400-500mg / L, SS: 100-200mg / L, pH value: 8.5.

[0062] Sewage treatment system:

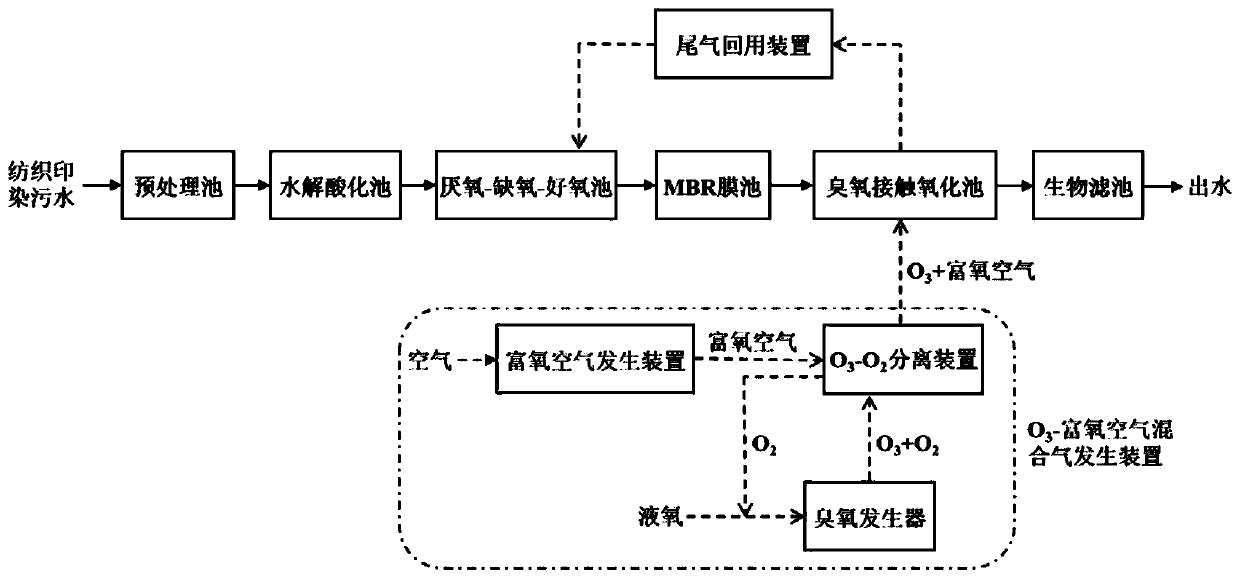

[0063] The selected advanced treatment system for textile printing and dyeing wastewater includes coagulation sedimentation tanks, hydrolytic acidification tanks, anaerobic-anoxic-aerobic tanks, MBR membrane tanks (equipped with submerged hollow fiber membrane modules), ozone contact oxidation pool and biological aerated filter; the coagulation sedimentation tank is connected with water inlet; the ozone contact oxidation tank is connected with O 3 -Oxygen-enriched air mixture generating device; said O 3 -Oxygen-enriched air mixture generating device consists of ozone generator, O 3 -O 2 Composed of separation device and oxygen-enriched air generator, O 3 -O 2 A silicate molecular sieve is installed in the separation devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com