Treatment and reusing device for kitchen waste

A kitchen garbage and garbage technology, applied in the direction of transportation and packaging, solid waste removal, chemical instruments and methods, etc., can solve the problems of increasing the pressure of urban sewage treatment, clogging sewers, difficult to promote and use, etc., to achieve easy operation and maintenance, convenient The effect of processing and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

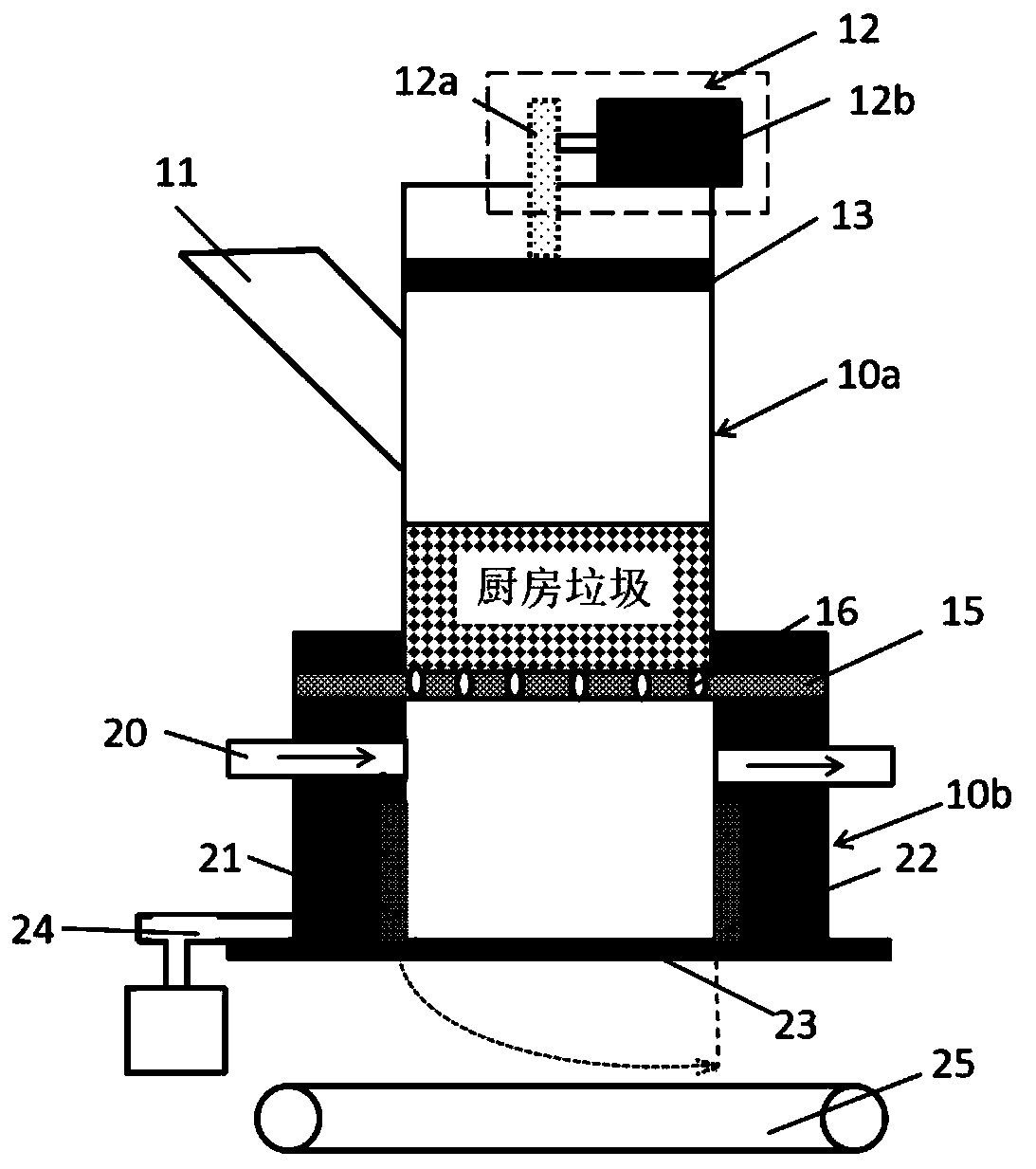

[0037] Such as figure 1 As shown, the compression crushing part and the drying and sterilization part are connected up and down for use, and the compression crushing part is mainly composed of a first cylinder 10a, a compression cover 13 and a compression bottom 15. A through hole 16 is provided on the compression bottom plate 15 . The compression bottom plate 15 is configured as a movable plate that can be pulled out horizontally from one side of the first cylindrical body 12a. After the garbage is put in from the feeding port 11, the compression cover plate 13 moves downward under the action of the drive unit 12 to compress the kitchen garbage into a cake shape while separating the solid and liquid from the compressed garbage. Then the compression bottom plate 15 is extracted from one side, and the treated garbage enters the drying and sterilization section below. Turn on the switch of the heating unit 21 and the sterilizing unit 22, and simultaneously blow air from the ai...

Embodiment 2

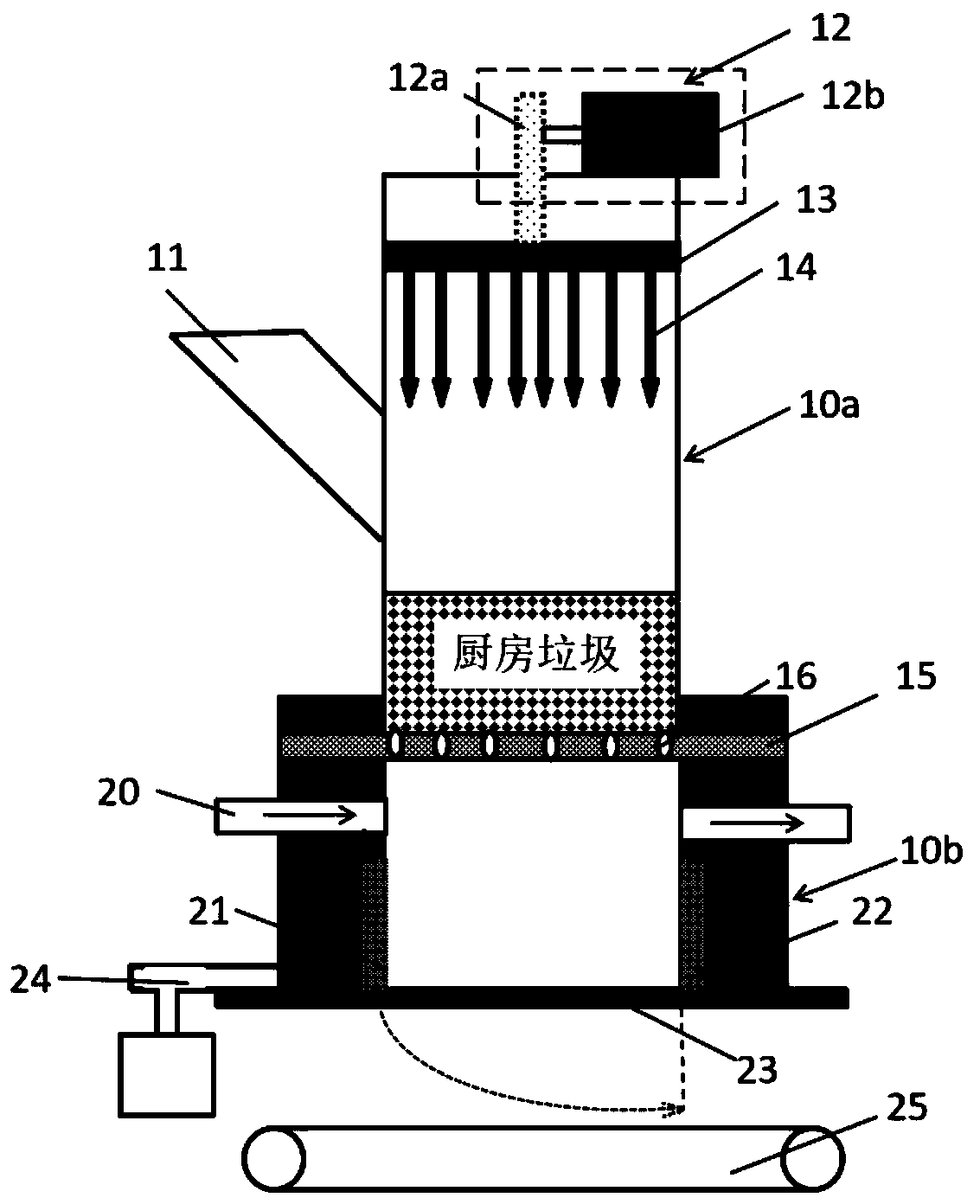

[0039] Such as figure 2 A kitchen garbage treatment and reuse device is shown, which includes a compression crushing part and a drying and sterilization part; the lower bottom surface of the compression cover 13 is provided with evenly distributed thorns 14, and the compression bottom 15 is provided with an adapter for the thorns 14 to pass through. Through hole 16, and the positions of thorn bar 14 and through hole 16 are corresponding. After putting in the garbage, the compression cover 13 moves under the action of the drive unit 12. While the compressed garbage is separated from solid and liquid, the stabbing rod 14 crushes the garbage. If there is hard garbage, repeat the operation several times, and finally the kitchen garbage is completely crushed. And compressed into a cake with honeycomb holes. The compression bottom plate 15 is extracted from one side, and the cake-shaped garbage enters the drying and sterilization section below. The honeycomb holes on the cake-sha...

Embodiment 3

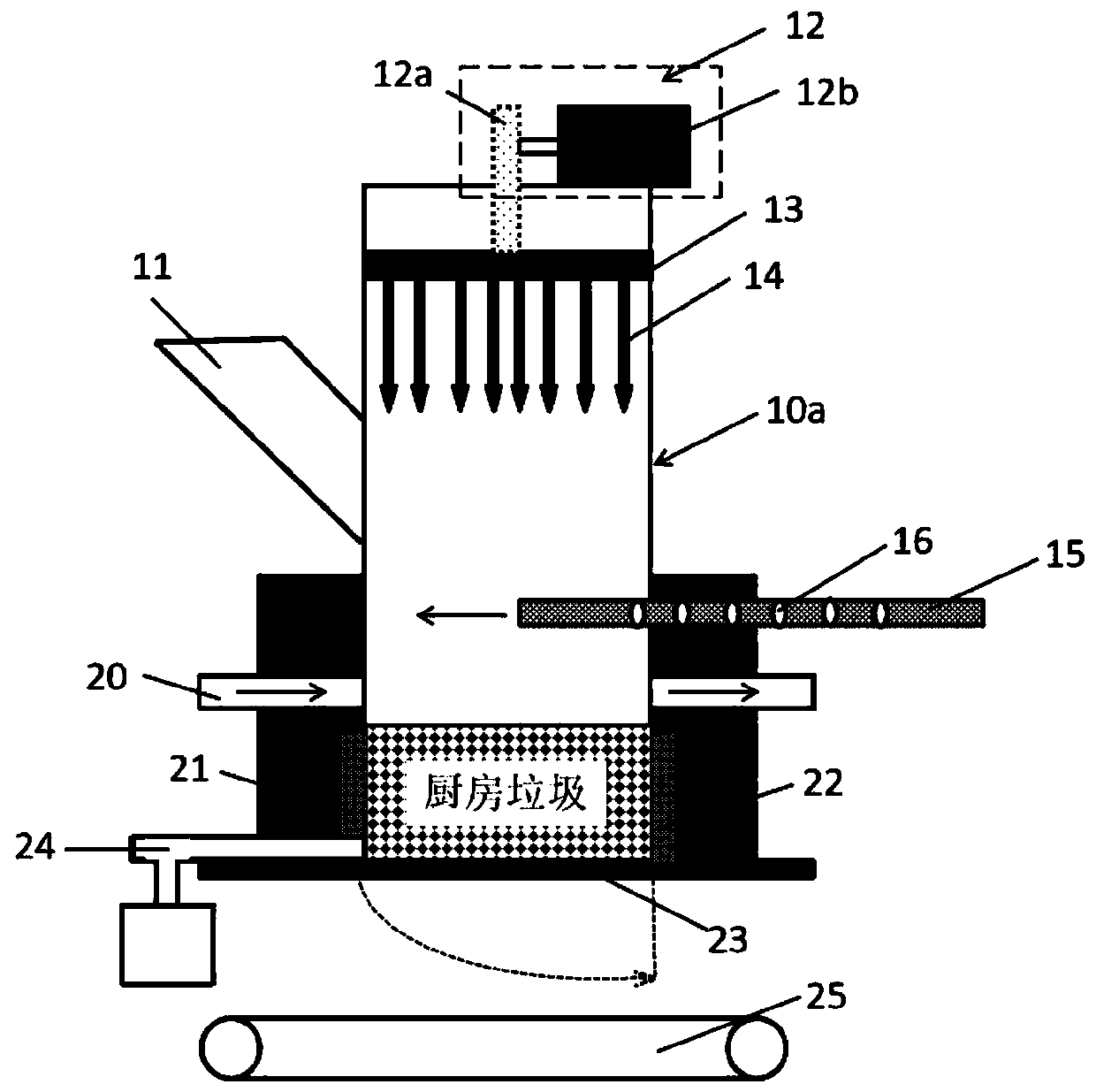

[0041] When the thorn bar 14 repeatedly compresses and pulverizes the kitchen waste, the waste may be stuck in the through hole 16 on the compression bottom plate 15, causing the through hole 16 to be blocked. Such as image 3 As shown, after the garbage enters the drying and sterilizing part, the compression bottom plate 15 is pushed back into the cylinder body 10a, the drive unit is opened to drive the compression cover plate 13 to move downward, and the thorn rod 14 passes through the through hole 16 on the compression bottom plate to clean up. The clogged garbage, thereby dredging the through hole 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com