Preparation process and application of Fe-based metal organic framework solid acid catalyst

A technology of solid acid catalyst and organic framework, which is applied in the direction of preparation of organic compounds, catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, etc. It can solve the problems of short service life and achieve long service life, Improve catalyst activity and repeated use times, and facilitate the effect of product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation technology of Fe-based metal organic framework solid acid catalyst, comprises the steps:

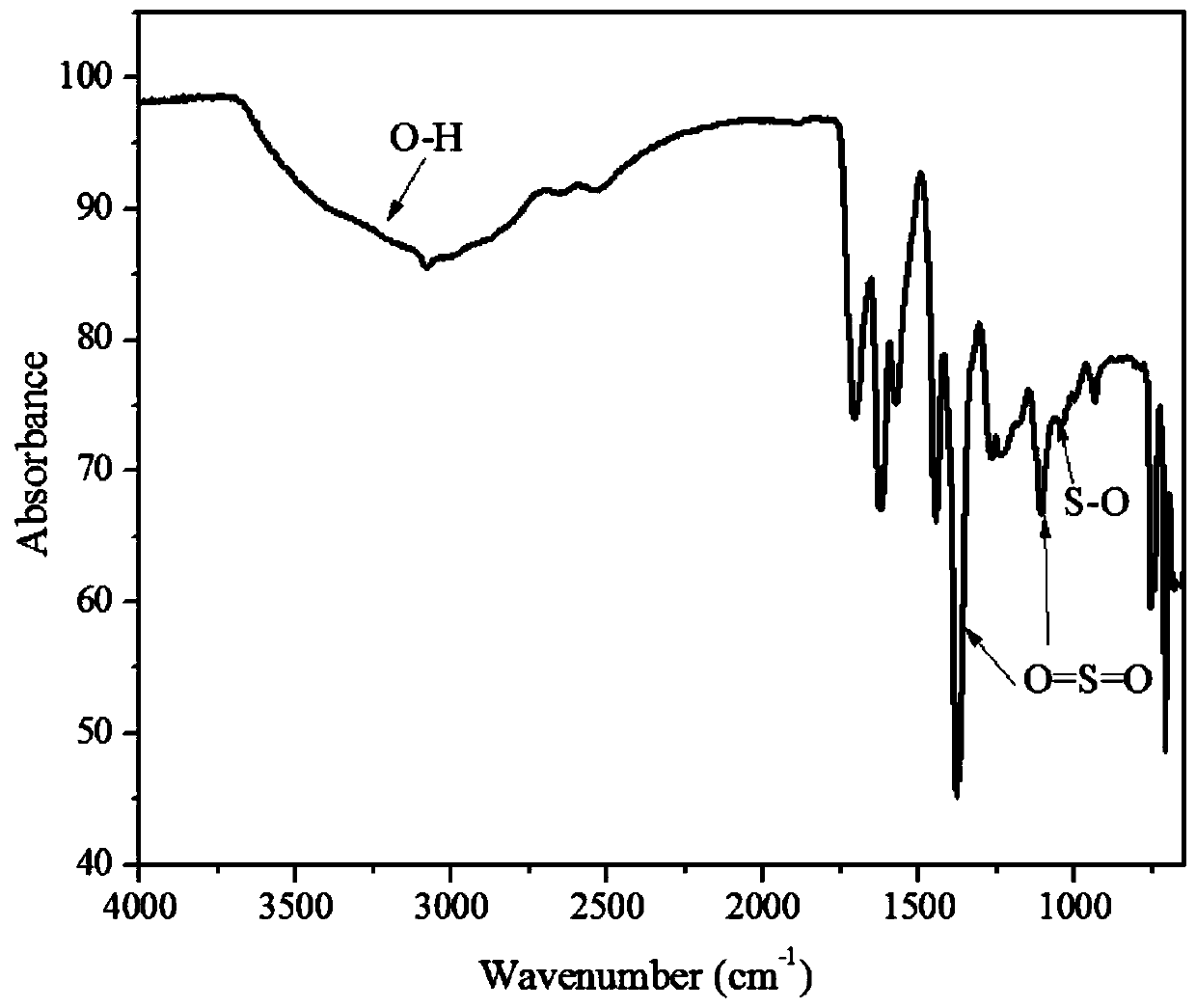

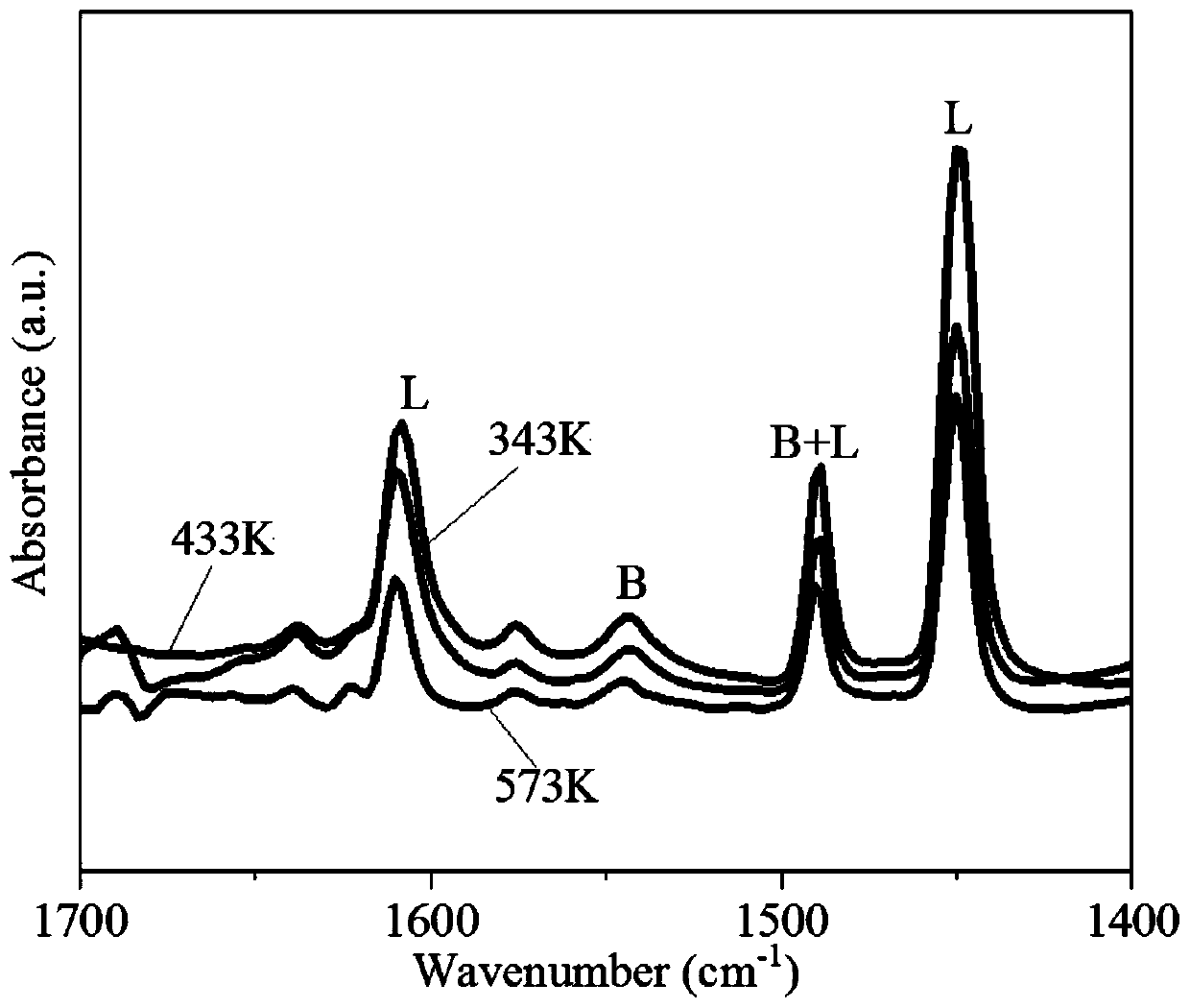

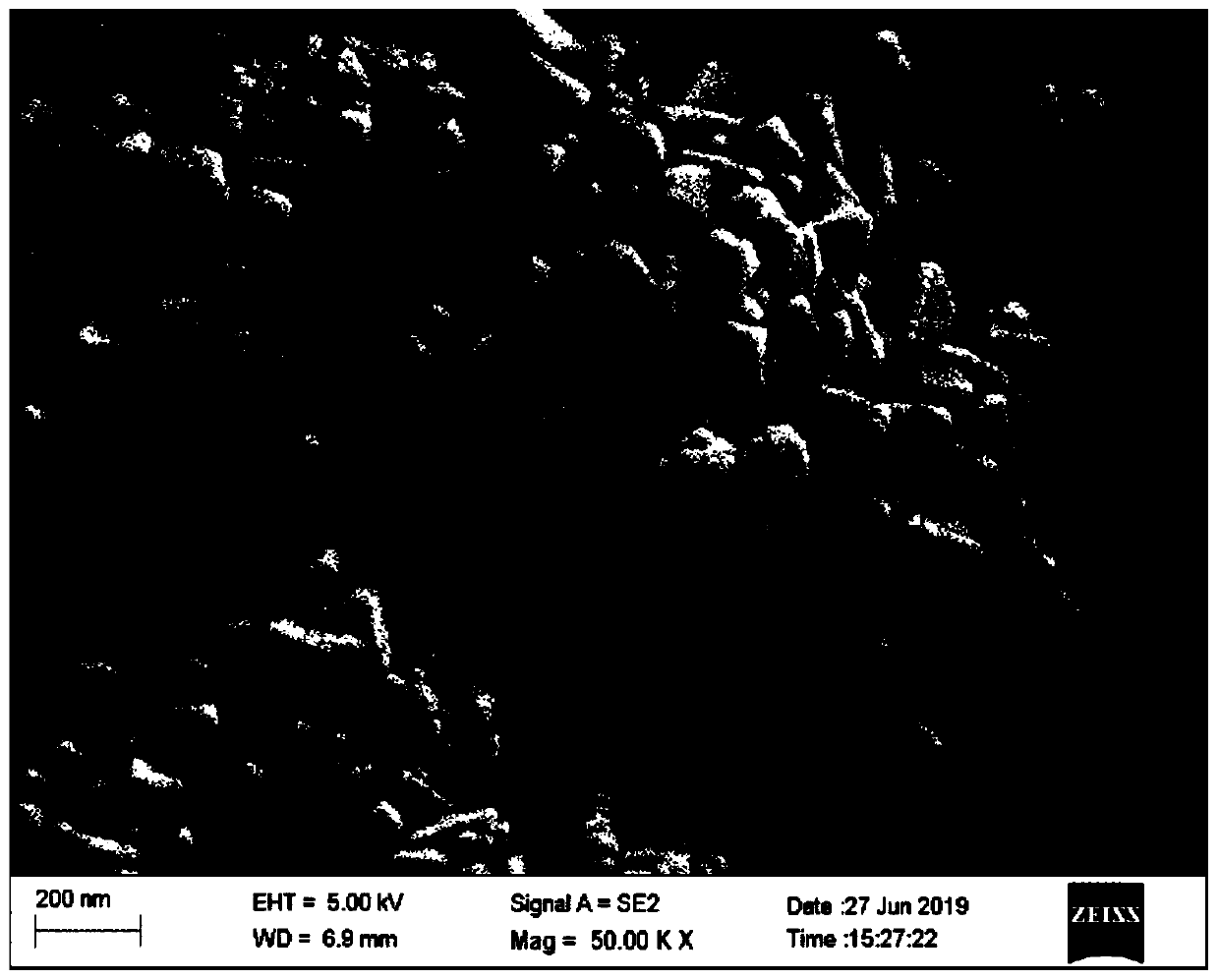

[0038] (1) Prepare a dilute sulfuric acid solution with a concentration of 0.8mol / L, then weigh 2gMIL-100(Fe) and add it to 25mL dilute sulfuric acid solution, stir at room temperature for 60min, pour the mixture into the hydrothermal reaction kettle, and use Heat the reactor to 60°C in a blast drying oven, heat for 30 hours and then cool to room temperature.

[0039] (2) Place the mixed material in the reaction kettle in a centrifuge, centrifuge at 3000r / min for 30min, remove the supernatant, put the obtained solid material in 200mL deionized water, stir and wash at 60°C for 30min, and filter to separate the solid product , if the filtrate pH<7, repeat this step until the filtrate pH=7, then filter to obtain the washing material.

[0040] (3) Dry the washed material in a blast drying oven at 130° C. for 20 hours, then transfer to a vacuum drying oven, and d...

Embodiment 2

[0043] A kind of preparation technology of Fe-based metal organic framework solid acid catalyst, comprises the steps:

[0044] (1) Prepare a dilute sulfuric acid solution with a concentration of 0.9mol / L, then weigh 2gMIL-100(Fe) and add it to 25mL of dilute sulfuric acid solution, stir at room temperature for 60min, pour the mixture into a hydrothermal reaction kettle, and use Heat the reactor to 160°C in a blast drying oven, heat for 15 hours and then cool to room temperature.

[0045] (2) Put the mixed material in the reaction kettle in a centrifuge, centrifuge at 3000r / min for 30min, remove the supernatant, put the obtained solid material in 200mL deionized water, stir and wash at 80°C for 20min, filter and separate the solid product , if the filtrate pH<7, repeat this step until the filtrate pH=7, then filter to obtain the washing material.

[0046] (3) The washed material was dried in a blast drying oven at 120° C. for 24 hours, then transferred to a vacuum drying oven,...

Embodiment 3

[0049] A kind of preparation technology of Fe-based metal organic framework solid acid catalyst, comprises the steps:

[0050] (1) Prepare a dilute sulfuric acid solution with a concentration of 1.0mol / L, then weigh 2gMIL-100(Fe) and add it to 25mL of dilute sulfuric acid solution, stir at room temperature for 60min, pour the mixture into a hydrothermal reaction kettle, and use Heat the reactor to 300°C in a blast drying oven, heat for 1 hour and then cool to room temperature.

[0051] (2) Put the mixed material in the reaction kettle in a centrifuge, centrifuge at 3000r / min for 30min, remove the supernatant, put the obtained solid material in 200mL deionized water, stir and wash at 40°C for 35min, and filter to separate the solid product , if the filtrate pH<7, repeat this step until the filtrate pH=7, then filter to obtain the washing material.

[0052] (3) Dry the washed material in a blast drying oven at 100° C. for 24 hours, then transfer to a vacuum drying oven, and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com