Gallic acid production waste biomass fuel and preparation method thereof

A technology of biomass fuel and gallic acid, which is applied in the direction of waste fuel, fuel, petroleum industry, etc., to achieve the effect of reducing space, reducing labor intensity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for producing biomass fuel by utilizing the waste residue of preparing gallic acid, wherein, the waste residue of preparing gallic acid includes wood fiber, activated carbon and water; the mass percentage of wood fiber in the waste residue is 25% to 30%; the mass percentage of waste activated carbon in the waste residue 30-40%; the mass percentage of water in the slag is 30-45%.

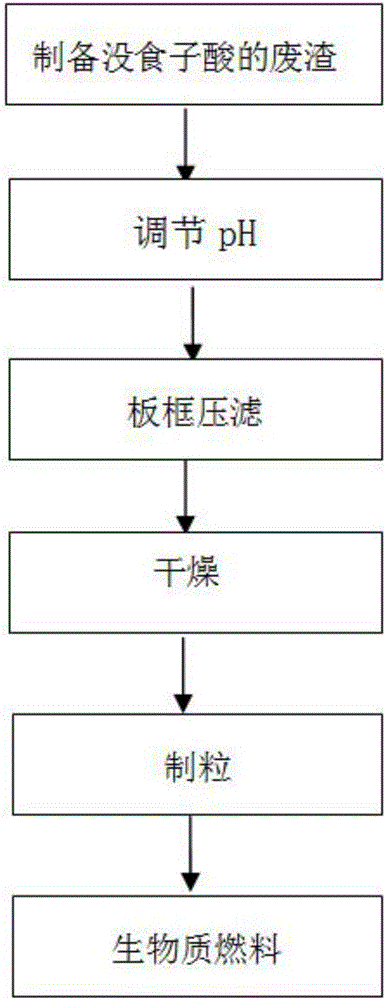

[0033] Such as figure 1 As shown, the method specifically includes the following steps:

[0034] (1) Add 1500L tap water in the enamel reactor of 3000L, turn on the stirring paddle, and add gallic acid waste residue 1000Kg (the water content is 45% in the assay) into the reactor; be heated to 85°C; The fraction is 30% sodium hydroxide solution, adjust the pH to pH 6, and keep warm for 10 minutes;

[0035] (2) Utilize plate and frame filter press to separate slag material and water, the pressure of plate and frame filter press is controlled at 0.2Mpa, obtain slag material (moisture c...

Embodiment 2

[0039] A kind of method utilizing the waste residue of preparing gallic acid to produce biomass fuel, described method specifically comprises the following steps:

[0040] (1) Add 1000L tap water in a 3000L enamel reaction kettle, turn on the stirring paddle, and add 1000Kg of gallic acid waste slag (moisture content is 45% as tested) into the reaction kettle with tara powder as raw material; heat to 95°C; Add a sodium hydroxide solution with a mass fraction of 50%, adjust the pH to 6.5, and keep warm for 30 minutes;

[0041](2) Utilize plate and frame filter press to separate slag material and water, the pressure of plate and frame filter press is controlled at 0.3Mpa, obtain slag material (assay to get water content to be 45%);

[0042] (3) the slag material that step (2) is obtained is dried through a vacuum drier, and the vacuum drier is controlled to be dried for 5 hours under the condition of -0.08~-0.09Mpa; %);

[0043] (4) Press the dried slag, and press it into gran...

Embodiment 3

[0045] A kind of method utilizing the waste residue of preparing gallic acid to produce biomass fuel, described method specifically comprises the following steps:

[0046] (1) Add 1750L tap water in the enamel reaction kettle of 3000L, open the stirring paddle, will be the waste residue 1000Kg (the moisture content is 45% that is tested to get water content) to add in the reaction kettle with Galla gall or tara powder as raw material production gallic acid; Heat to 90 ℃; add a sodium hydroxide solution with a mass fraction of 40%, adjust the pH to a pH of 7, and keep warm for 20 minutes;

[0047] (2) Using a plate and frame filter press to separate the slag from water, controlling the pressure of the plate and frame filter at 0.2 to 0.3Mpa to obtain the slag;

[0048] (3) The slag material that step (2) is obtained is dried through a vacuum drier, and the vacuum drier is controlled to dry for 4 hours under the condition of -0.08~-0.09Mpa; %);

[0049] (4) Press the dried sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com