A melt polycondensation reactor

A melt polycondensation and reactor technology, applied in the field of melt polycondensation reactor equipment, can solve the problems of limiting melt film forming efficiency and surface renewal frequency, insufficient material reaction temperature, poor melt flow conditions, etc., to achieve film formation The effect of large area and surface renewal rate, uniform and controllable residence time, simple feasibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

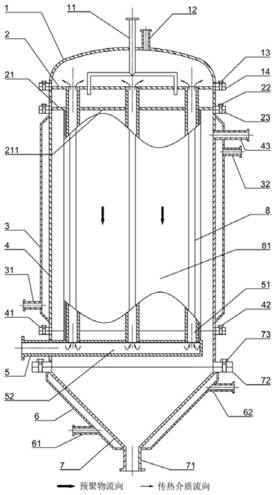

[0037] Example 1: Falling film channel with semi-circular cross-section is used for polyester (PET) melt polycondensation to increase viscosity

[0038] The structure and principle of the reactor are as described above, and the present embodiment adopts figure 1 The first structure of the polycondensation reactor shown, the cross-section of the falling film channel of the plate falling film element is semicircular, and the structure of part of the reactor is as follows: there are six semicircular falling film channels on the plate falling film element, each The opening distance (L) of the falling film flow channel is 10-50 mm, the depth (H) is L / 2, and the center-to-center distance (D) of two adjacent flow channels on the same side is 20-70 mm. The polyester (PET) prepolymerization material with a viscosity of 0.65 dL / g flows into the melt polycondensation reactor through the feed pipe, and flows down to the semicircular falling film channel of the plate falling film element t...

Embodiment 2

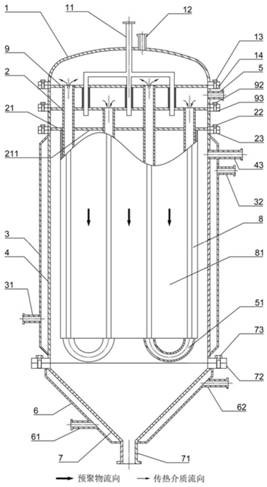

[0039] Example 2: Trapezoidal cross-section falling film flow channel is used for PET melt polycondensation to increase viscosity

[0040] In this embodiment, a plate-type falling film element with a trapezoidal cross-section of the falling film flow channel is used, and the opening distance of each falling film flow channel (L 1 ) is 10~50 mm, concave straight wall (L 2 ) is 5~40 mm, the depth (H) is 10~15 mm, the center-to-center distance (D) of two adjacent flow channels on the same side is 20~70 mm, and there are six flow channels on the element; the rest of the reactor structure is the same as the implementation The same as Example 1, the PET prepolymer forms a film on the falling film flow channel and slides down to complete the polycondensation and increase the viscosity. 0.87 dL / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com