Method for preparing high-silicon aluminum alloy rheological slurry

A high-silicon aluminum alloy and aluminum alloy technology, applied in the field of semi-solid metal forming, can solve the problems of large grain growth driving force, limited alloy quality, ineffective eutectic silicon, etc., and achieve excellent mechanical properties, good surface quality, inhibiting effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1Al-18

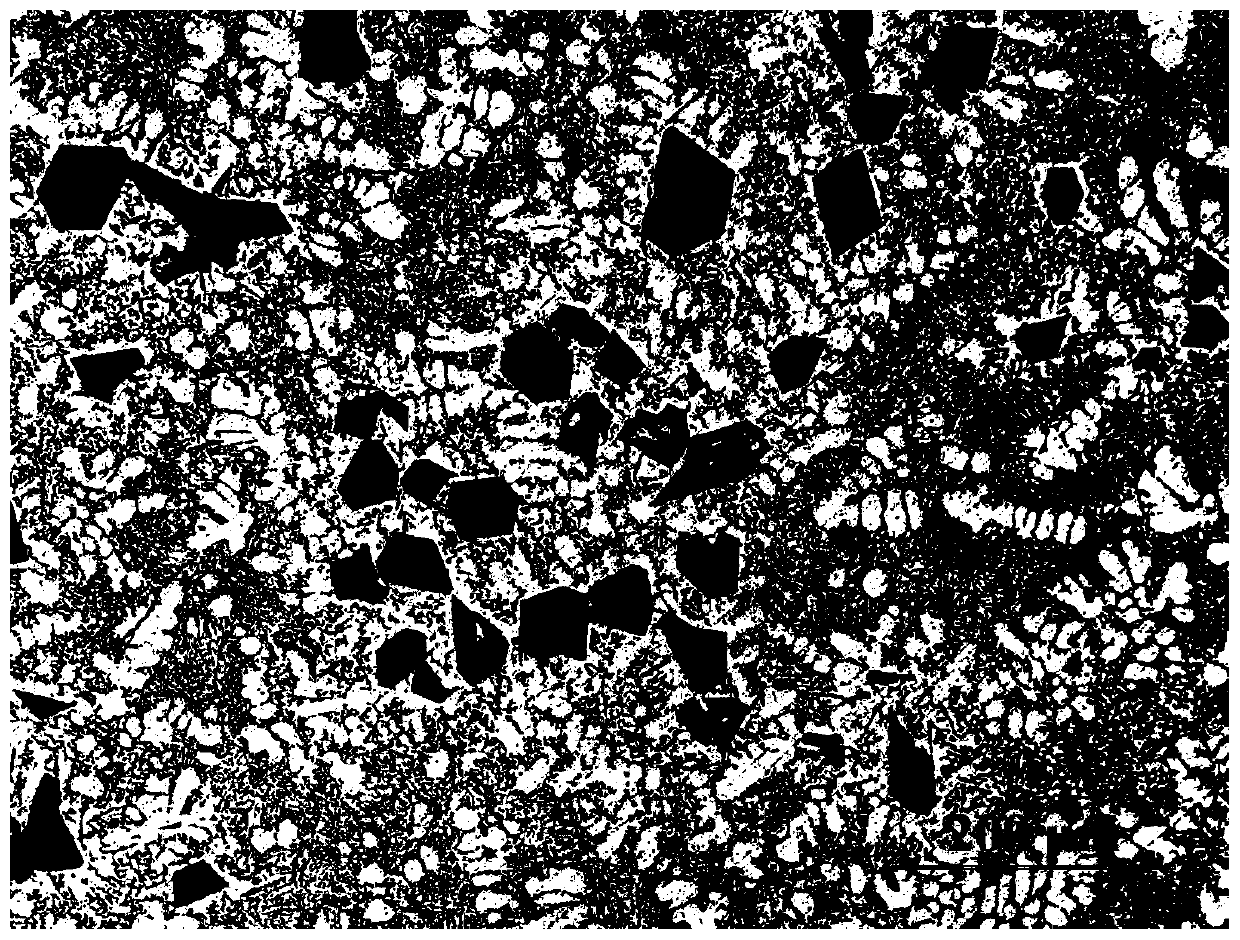

[0051] Example 1 Al-18Si alloy primary silicon refinement and preparation of rheological slurry

[0052] After the Al-18Si alloy is preheated for 1.5-2 hours to reach 150-200°C, the alloy is melted in an industrial electric furnace. After the alloy is melted, stir at a temperature of 50-70°C higher than the liquidus temperature, and let stand for 10-20 minutes for the first time. Preheat the rare earth lanthanum for 1-2 hours to reach 100-200°C, set the temperature of the Al-18Si alloy melt at 30-50°C higher than the liquidus temperature, and add lanthanum at 1 wt% of the mass of the Al-18Si alloy melt, Stir well and let stand for 10-20 minutes for the second time. Then, control the temperature of the Al-18Si alloy melt to 800° C. for refining, keep the temperature for 5 to 15 minutes for stirring, remove slag, and stand still for 10 minutes for the third time.

[0053] Lower the temperature of the Al-18Si alloy melt to 750°C, set the inclination angle of the mechanical drum...

Embodiment 2

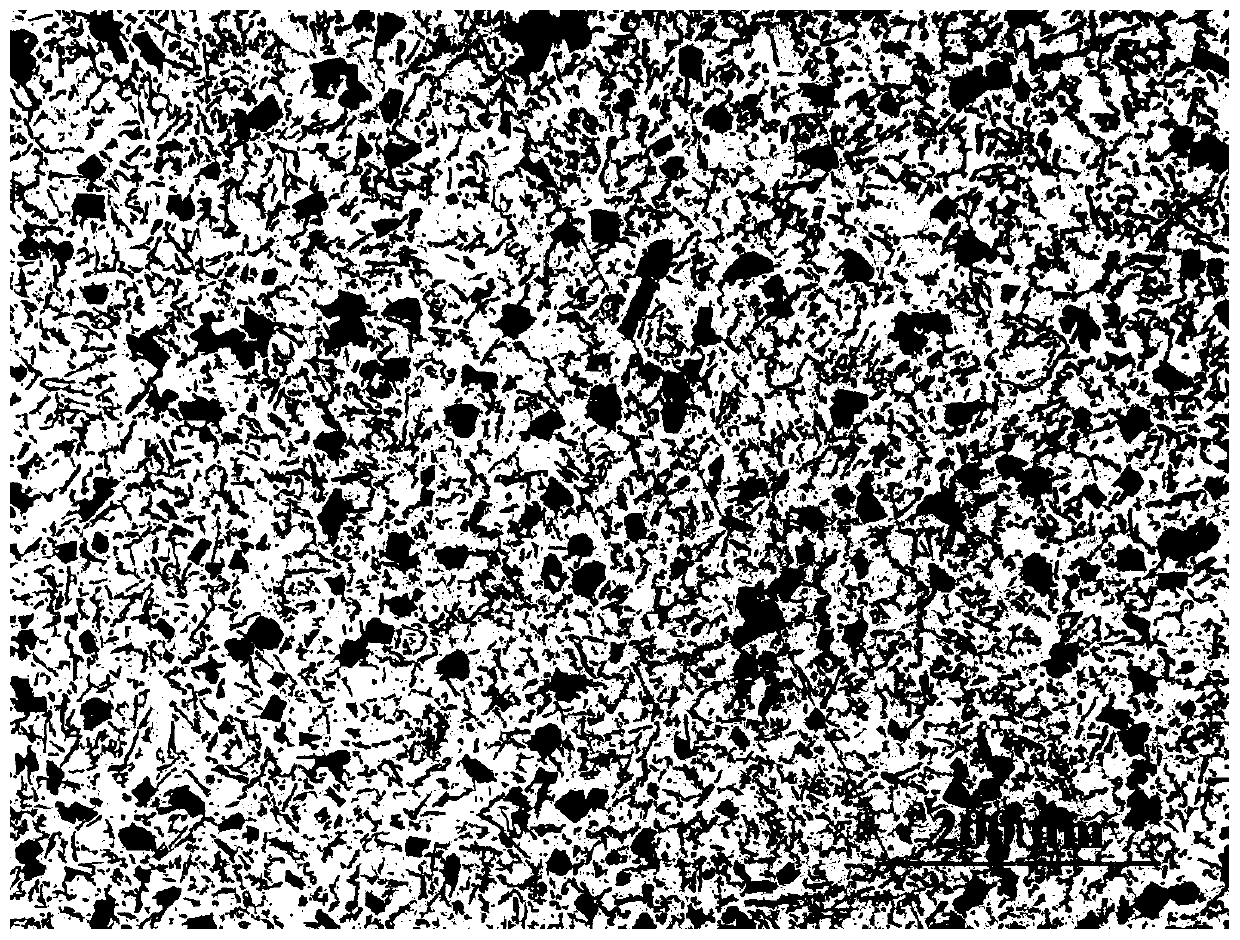

[0055] Example 2 2Al-18Si Alloy Primary Silicon Refinement and Preparation of Rheological Slurry

[0056] After the Al-18Si alloy is preheated for 1.5-2 hours to reach 150-200°C, the alloy is melted in an industrial electric furnace. After the alloy is melted, stir at a temperature of 50-70°C higher than the liquidus temperature, and let stand for 10-20 minutes for the first time. Preheat the rare earth cerium to 100-200°C for 1-2 hours, set the temperature of the Al-18Si alloy melt at 30-50°C higher than the liquidus temperature, and add cerium at 0.1wt% of the mass of the Al-18Si alloy melt , stir well, and let stand for 10-20 minutes for the second time. Then, control the temperature of the Al-18Si alloy melt to 780° C. for refining, keep the temperature for 5 to 15 minutes for stirring, remove slag, and stand still for 15 minutes for the third time.

[0057] Lower the temperature of the Al-18Si alloy melt to 770°C, set the inclination angle of the mechanical drum relativ...

Embodiment 3Al-30

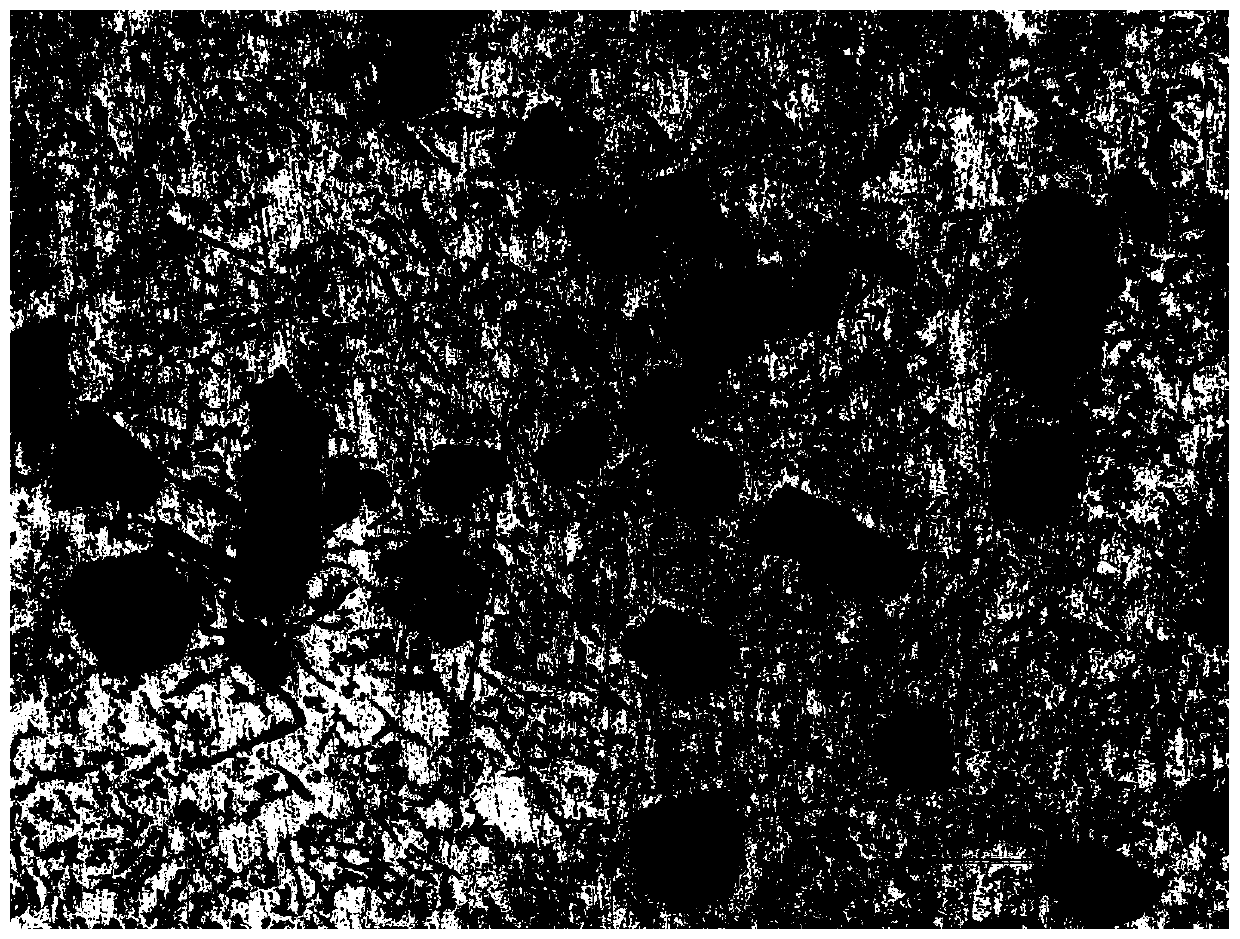

[0058] Example 3 Al-30Si alloy primary silicon refinement and preparation of rheological slurry

[0059] After the Al-30Si alloy is preheated for 1.5-2 hours to reach 150-200°C, the alloy is melted in an industrial electric furnace. After the alloy is melted, stir at a temperature of 50-70°C higher than the liquidus temperature, and let stand for 10-20 minutes for the first time. Preheat the rare earth lanthanum for 1-2 hours to reach 100-200°C, set the temperature of the Al-30Si alloy melt at 30-50°C higher than the liquidus temperature, and add lanthanum at 3 wt% of the mass of the Al-30Si alloy melt, Stir well and let stand for 10-20 minutes for the second time. Then, control the temperature of the Al-30Si alloy melt to be refined at 850° C., keep the temperature for 5 to 15 minutes for stirring, remove slag, and stand still for 15 minutes for the third time.

[0060] Adjust the temperature of the Al-30Si alloy melt to 850°C, set the inclination angle of the mechanical dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com