Low-temperature-resistant liquid alkali-free accelerator and preparation method thereof

An accelerator and anti-low temperature technology, applied in the field of concrete admixtures, can solve the problems of easy crystallization, injury and stimulation of construction personnel, etc., and achieve the effects of improving product stability, solving easy freezing and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

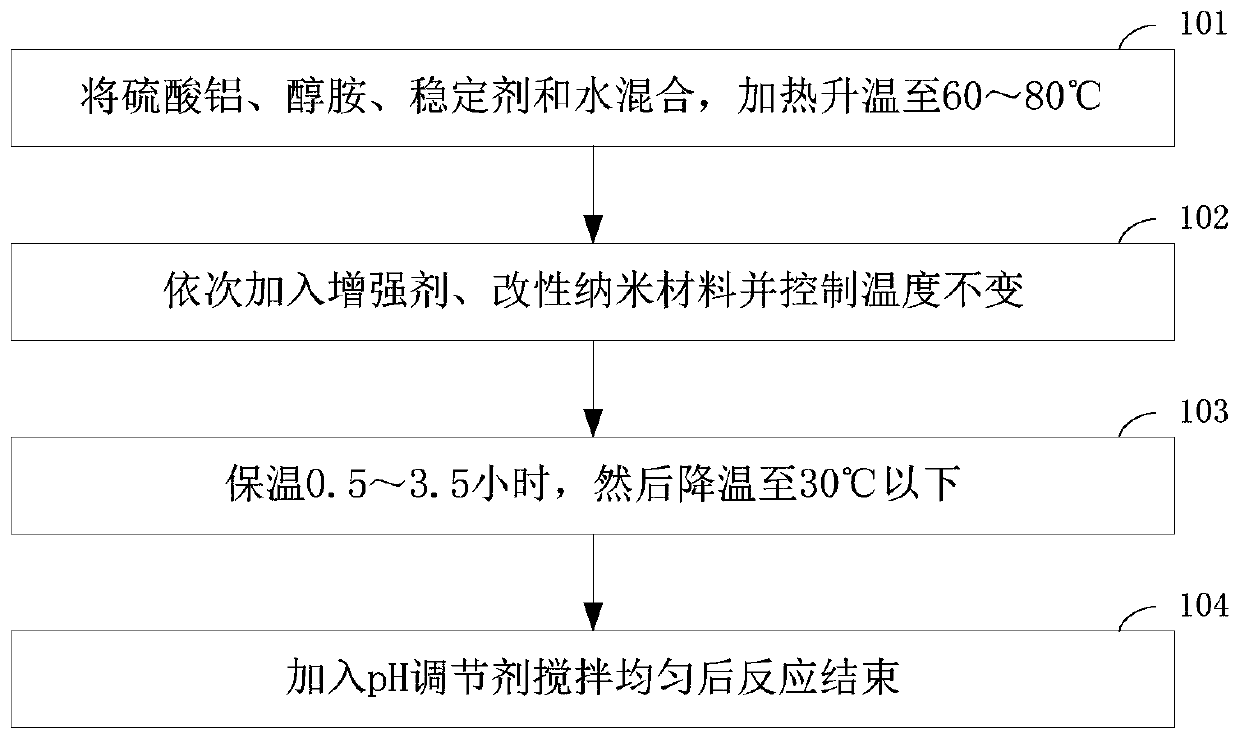

[0052] figure 1 It is a schematic flow chart of the preparation method of the low temperature resistant liquid alkali-free accelerator in the embodiment of the present invention. like figure 1 As shown, the preparation method of the anti-low temperature type liquid alkali-free accelerator in the embodiment of the present invention comprises the following steps:

[0053] Step 101, mixing aluminum sulfate, alcohol amine, stabilizer and water, and heating to 60-80°C.

[0054] Step 102, adding reinforcing agent and modified nanomaterials in sequence while controlling the temperature to remain constant.

[0055] Step 103, keep warm for 0.5-3.5 hours (h), and then lower the temperature to below 30°C.

[0056] Step 104, adding a pH regulator and stirring evenly, and then the reaction ends.

[0057] Through the above-mentioned steps 101-104, the above-mentioned anti-low temperature type liquid alkali-free accelerator can be prepared.

specific Embodiment 1

[0060] In this specific example one, the preparation method of anti-low temperature type liquid alkali-free quick-setting agent comprises the following steps:

[0061] Step 11, mix 50 grams (g) of aluminum sulfate, 10 g of alcohol amine, 0.05 g of stabilizer and 29.95 g of water, and heat up to 80°C.

[0062] In step 12, add 4 g of reinforcing agent and 1 g of modified nanomaterial in sequence and keep the temperature constant.

[0063] Step 13, keep warm for 3.5 hours, and then lower the temperature to below 30°C.

[0064] Step 14, add 1g of pH adjuster and stir evenly, and then the reaction ends.

[0065] Through the above-mentioned steps 11-14, the above-mentioned anti-low temperature type liquid alkali-free accelerator can be prepared.

specific Embodiment 2

[0067] In this specific example two, the preparation method of anti-low temperature type liquid alkali-free accelerator comprises the following steps:

[0068] Step 21, mix 40g of aluminum sulfate, 5g of alcohol amine, 0.01g of stabilizer and 45.99g of water, and heat up to 60°C.

[0069] In step 22, add 6 g of reinforcing agent and 2 g of modified nanomaterials in sequence and keep the temperature constant.

[0070] Step 23, keep warm for 2.5 hours, and then lower the temperature to below 30°C.

[0071] Step 24, add 1g of pH adjuster and stir evenly, and then the reaction ends.

[0072] Through the above-mentioned steps 21-24, the above-mentioned anti-low temperature type liquid alkali-free accelerator can be prepared.

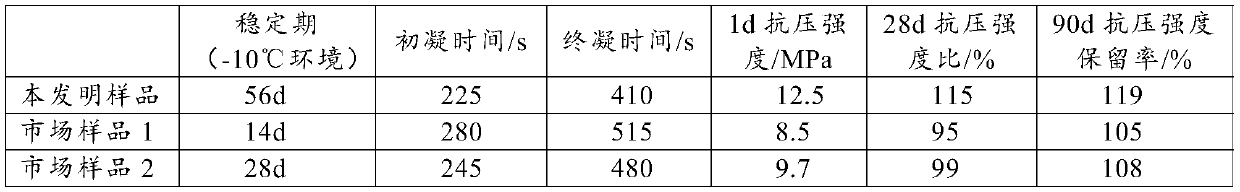

[0073] The anti-low temperature type alkali-free accelerator provided in the technical solution of the present invention can significantly reduce the freezing point of the alkali-free accelerator solution, thereby preventing the accelerator from freezing or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com