Environment-friendly composite plastic with pearlescent effect and preparation method thereof

A pearlescent effect and composite plastic technology, applied in the field of polymer materials, can solve the problems of high cost, environmental protection, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

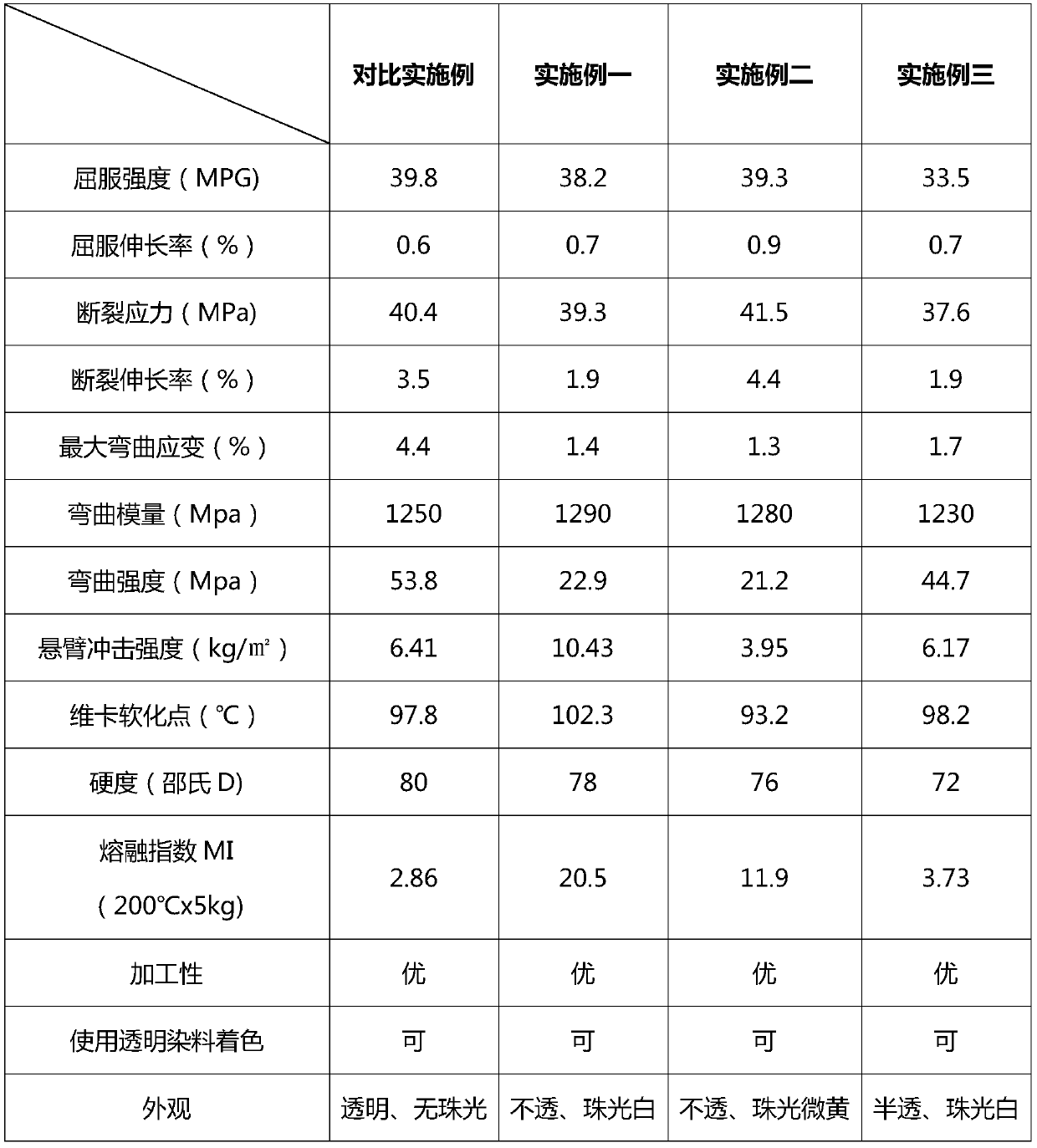

Examples

preparation example Construction

[0047]According to an embodiment of the present invention, there is also provided a preparation method for implementing the above-mentioned environment-friendly composite plastic with pearlescent effect, including:

[0048] Raw material pretreatment: dehumidify, crush and sieve each component in the raw material;

[0049] Raw material preparation: weigh each component in the raw material according to the ratio;

[0050] Raw material premixing: physically mix the components in the raw material;

[0051] Extruder processing: feed the raw materials into the extruder for melt homogenization, devolatilization treatment and extrusion granulation.

[0052] It should be noted that the processing steps of the extruder can also be completed in different equipments for melting homogenization, devolatilization treatment and extrusion granulation respectively. The extruder configuration should not limit the preparation method of the present application.

[0053] As a specific solution, ...

Embodiment 1

[0066] The components and proportioning ratio of Embodiment 1 are shown in Table 2.

[0067] Its specific preparation process is as follows: using the same equipment and operating conditions as the comparative example, the stirring speed is 2000rpm, and the time is divided into 2 minutes and 3 minutes (sampling observation in the middle). Adopt the same equipment with comparative example, and process condition is also similar. The maximum temperature and the template temperature were lowered by 10°C each. The screw speed was adjusted to 150 rpm.

[0068] name quantity name quantity 803 100 1010 0.6 POM 100 168 0.6 SAN 40 SiO2 0.5 HIPS 20 Interacid amide 0.5 P-G-MAH 5 376 0.2 PEG 3 Cast 0.2 POE 2 Microcrystalline Wax 0.1 EBS 0.7

[0069] Component composition and proportioning of table 2 embodiment one

Embodiment 2

[0071] The components and proportioning ratio of Embodiment 1 are shown in Table 3. Its specific preparation process is the same as the comparative example.

[0072] name quantity name quantity 803 100 1010 0.7 PBT 100 168 0.5 PP 25 PEST 0.2 SAN 25 531 0.15 P-G-MAH 8 Cast 0.1 POE 6 Hst 0.2 EBS 0.8 Microcrystalline Wax 0.1

[0073] Component constitution and proportioning of table 3 embodiment two

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com