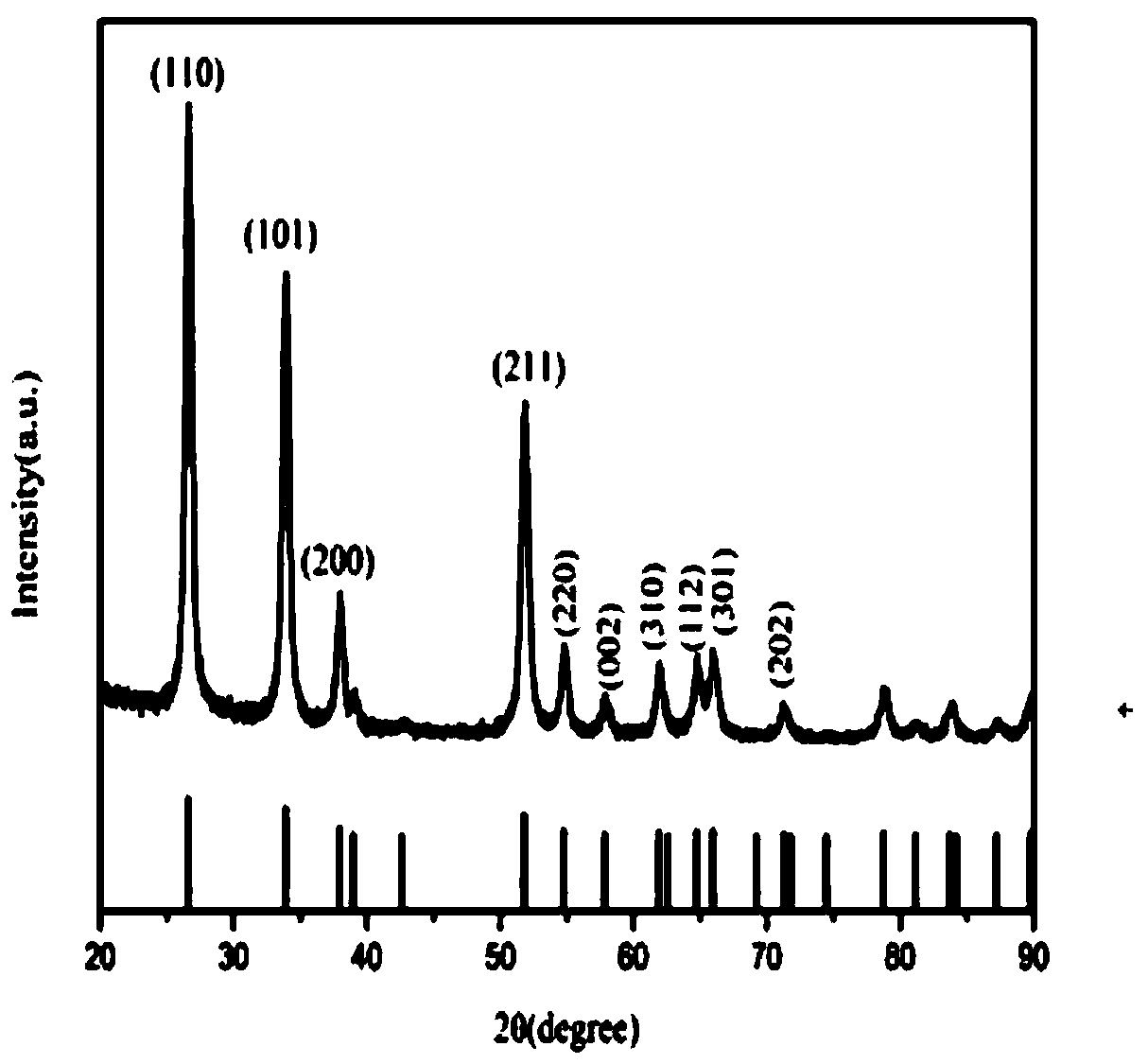

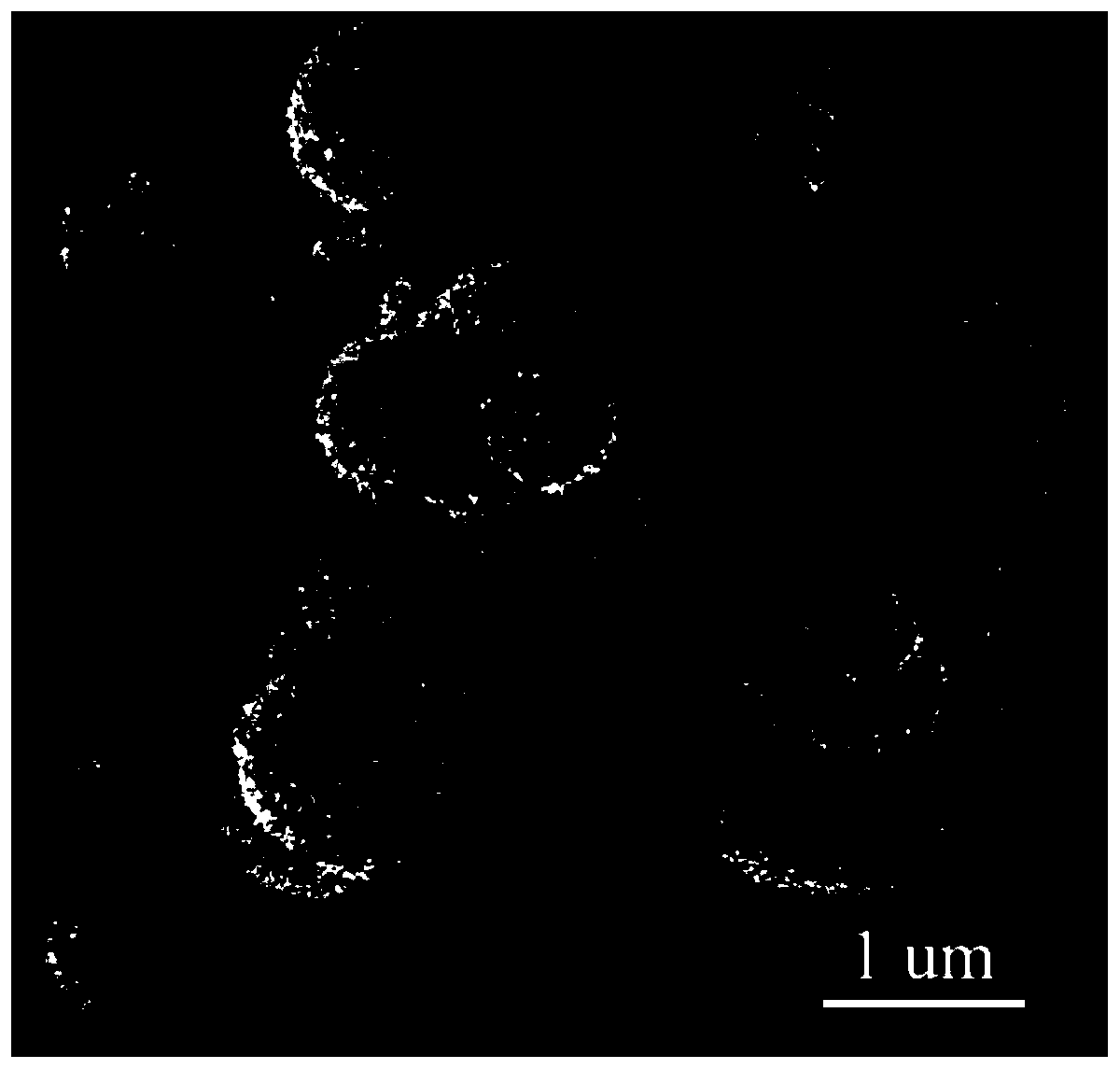

Graded core-shell SnO2 microspheres as well as preparation method and application thereof

A technology of microspheres and cores, applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of long response recovery time, high working temperature, poor sensitivity, etc., and achieve the promotion of adsorption and transmission, large pores The effect of high efficiency and raw materials is environmentally friendly and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A Hierarchical Core-Shell SnO 2 Microsphere, its preparation method comprises the steps:

[0046] 1) Weigh 0.65g SnSO with an analytical balance 4 Put the powder in a 50ml beaker, then use a measuring cylinder to measure 30ml of deionized water and pour it into the beaker, then place the beaker on a magnetic stirrer to stir, then continue to weigh 1.19g of D-glucose powder with a balance and slowly pour it into the In the stirring beaker, finally weigh 0.36g of urea particles and slowly pour it into the stirring beaker, and continue magnetic stirring for 60min to obtain a suspended precursor solution;

[0047] 2) Transfer the obtained precursor liquid into a 100ml hydrothermal reaction kettle, and react in a constant temperature box at 180°C for 12 hours. After the reaction is completed and cooled naturally, use deionized water and ethanol to cross-centrifuge and wash 3 times each to obtain a dark brown precipitate. The precipitate was dried overnight at 80°C, and the d...

Embodiment 2

[0050] A Hierarchical Core-Shell SnO 2 Microsphere, its preparation method comprises the steps:

[0051] 1) Weigh 0.64gSnSO4 with an analytical balance 4 Put the powder in a 50ml beaker, then use a measuring cylinder to measure 30ml of deionized water and pour it into the beaker, then place the beaker on a magnetic stirrer to stir, then continue to weigh 1.18g of D-glucose powder with a balance and slowly pour it into the stirring Finally, weigh 0.36g of urea particles and slowly pour it into the stirring beaker, and continue magnetic stirring for 60min to obtain a suspension of the precursor solution;

[0052] 2) Transfer the obtained precursor solution into a 100ml hydrothermal reaction kettle, and react in a constant temperature box at 180°C for 24 hours. After the reaction is completed and cooled naturally, use deionized water and ethanol to cross-centrifuge and wash 3 times each to obtain a dark brown precipitate. The precipitate was dried overnight at 80°C, and the dri...

Embodiment 3

[0055] A Hierarchical Core-Shell SnO 2 Microsphere, its preparation method comprises the steps:

[0056] 1) Weigh 0.62gSnSO4 with an analytical balance 4 Put the powder in a 50ml beaker, then use a measuring cylinder to measure 30ml of deionized water and pour it into the beaker, then put the beaker on a magnetic stirrer to stir, then continue to weigh 1.19g of D-glucose powder with a balance and slowly pour it into the stirring Finally, weigh 0.35g of urea particles and slowly pour it into the stirring beaker, and continue magnetic stirring for 60min to obtain a suspension of the precursor solution;

[0057] 2) Transfer the precursor liquid into a 100ml hydrothermal reaction kettle, and react in a constant temperature box at 180°C for 18 hours. After the reaction is completed and cooled naturally, use deionized water and ethanol to cross-centrifuge and wash 3 times each to obtain a dark brown precipitate. The precipitate was dried overnight at 80°C, and the dried precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com