An ecological decorative diatom mud-artificial sandstone composite board and its preparation method

A technology of artificial sandstone and diatom mud, applied in ceramic products, building structures, other household appliances, etc., can solve the problems of easy detachment of diatom mud and photocatalyst components, shortened service life, reduced adsorption effect, etc., to achieve excellent breathing Humidity control function, easy to use, increase the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

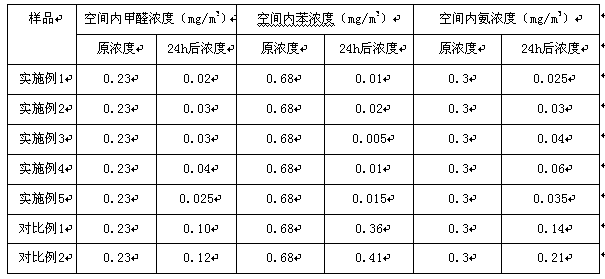

Examples

Embodiment 1

[0025] A method for preparing an ecologically decorated diatom mud-artificial sandstone composite board, comprising the following steps:

[0026] (1) 5 parts by weight of MoS with a particle size of less than 100 nanometers 2 Add 20 parts by weight of diatomaceous earth into water, stir and disperse evenly, dry, pass through a 0.1mm square hole sieve, pass through a laser scanning bed, use a carbon dioxide laser as the laser source, the power is 300W, and the welding scanning speed is 20mm / s; Grade photocatalyst is fixed in the micropores of diatomite to obtain modified diatomite powder;

[0027] (2) Mix the modified diatomite powder with 50 parts by weight of porous volcanic rock and 20 parts by weight of calcium hydroxide, and add water according to the solid-liquid volume ratio of 1:0.5 to make a mixed slurry;

[0028] (3) Mix the mixed slurry obtained in step (2) with 5 parts by weight of sodium bicarbonate capsules evenly, quickly transfer them to a mold, and conduct a h...

Embodiment 2

[0030] A method for preparing an ecologically decorated diatom mud-artificial sandstone composite board, comprising the following steps:

[0031] (1) Add 6 parts by weight of ZnO with a particle size of less than 100 nanometers and 25 parts by weight of diatomaceous earth into water, stir and disperse evenly, dry, pass through a 0.1mm square hole sieve, pass through a laser scanning bed, and use a carbon dioxide laser as a laser source. The power is 400W, and the welding scanning speed is 25mm / s; the nano-scale photocatalyst is fixed in the micropores of diatomite to obtain modified diatomite powder;

[0032] (2) Mix the modified diatomite powder with 60 parts by weight of porous volcanic rock and 20 parts by weight of calcium hydroxide, and add water according to the solid-liquid volume ratio of 1:0.5 to make a mixed slurry;

[0033](3) Mix the mixed slurry obtained in step (2) with 10 parts by weight of sodium bicarbonate capsules evenly, quickly transfer them to a mold, and...

Embodiment 3

[0035] A method for preparing an ecologically decorated diatom mud-artificial sandstone composite board, comprising the following steps:

[0036] (1) 8 parts by weight of TiO with a particle size less than 100 nanometers 2 Add 50 parts by weight of diatomaceous earth into water, stir and disperse evenly, dry, pass through a 0.1mm square hole sieve, pass through a laser scanning bed, use a carbon dioxide laser as the laser source, the power is 300W, and the welding scanning speed is 30mm / s; Grade photocatalyst is fixed in the micropores of diatomite to obtain modified diatomite powder;

[0037] (2) Mix the modified diatomite powder with 100 parts by weight of porous volcanic rock and 30 parts by weight of calcium hydroxide, and add water according to the ratio of solid-liquid volume ratio of 1:1 to make a mixed slurry;

[0038] (3) Mix the mixed slurry obtained in step (2) with 10 parts by weight of sodium bicarbonate capsules evenly, quickly transfer them to a mold, and condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com