Preparation method of suspended assembled floor with adsorption function

A floor and functional technology, which is applied in the field of preparation of suspended assembled floors, can solve problems such as inability to achieve air purification and lack of adsorption capacity, and achieve the effect of retaining porous adsorption characteristics, good environmental protection significance, and reliable adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

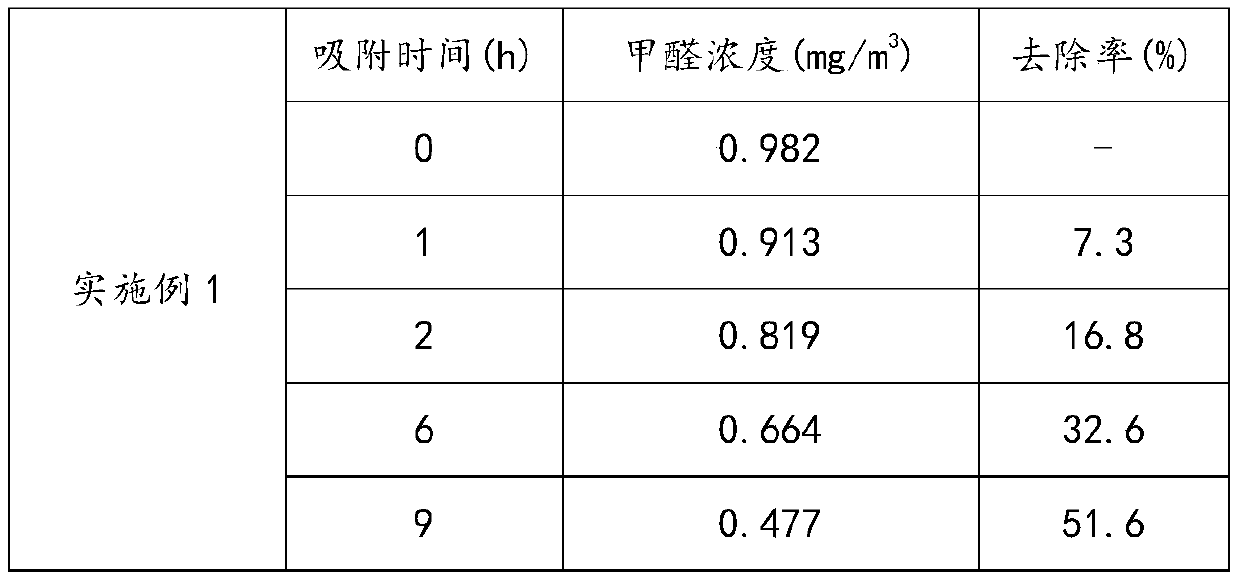

Embodiment 1

[0031] The suspended assembled floor provided in this embodiment includes, by mass percentage, 50% of modified sepiolite, 25% of SEBS, 35% of nano filler, and the balance is polypropylene.

[0032] Wherein, the SEBS is the YH-511 SEBS produced by Baling Petrochemical;

[0033] The model produced by Jing Kelin in the nano-filler is a novel inorganic filler of PO789;

[0034] Described polypropylene is No. 150 PP produced by Baling Petrochemical;

[0035] The preparation method of described modified sepiolite is as follows:

[0036] Crush and grind the natural sepiolite to 50 mesh, pass through 50 sieves, put the natural sepiolite powder and water into deionized water at a mass ratio of 1:25, and then stir evenly to obtain a sepiolite suspension. Then absolute ethanol (mass ratio of absolute alcohol to sepiolite is 1:2.3) and 3-mercaptopropyltrimethoxysilane (mass ratio of 3-mercaptopropyltrimethoxysilane to sepiolite is 1 : 4.7) mixed with each other evenly to make a mixing ...

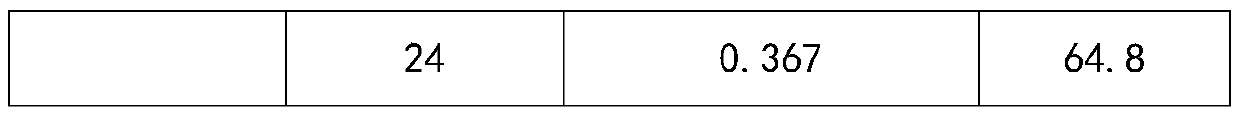

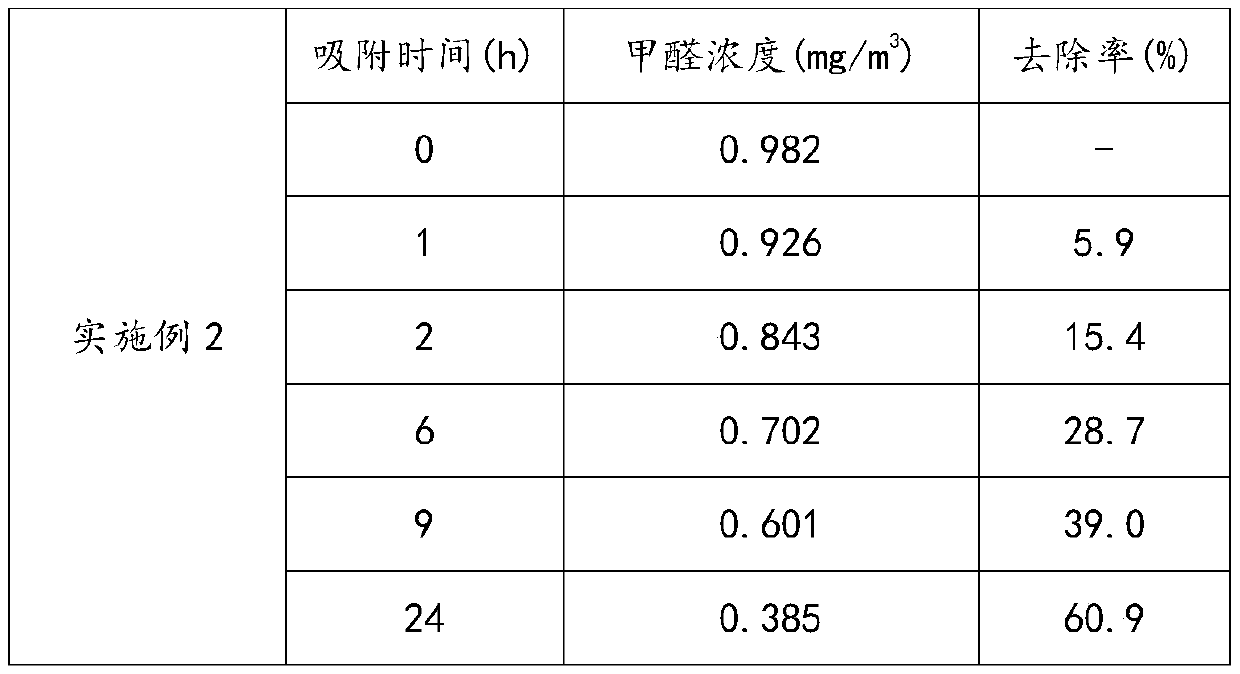

Embodiment 2

[0041] The suspended assembled floor provided in this embodiment includes, by mass percentage, 16% of modified sepiolite, 15% of SEBS, 20% of nano filler, and the balance is polypropylene.

[0042] Wherein, the SEBS is the YH-511 SEBS produced by Baling Petrochemical;

[0043] The model produced by Jing Kelin in the nano-filler is a novel inorganic filler of PO789;

[0044] Described polypropylene is No. 150 PP produced by Baling Petrochemical;

[0045] The preparation method of described modified sepiolite is as follows:

[0046] Crush and grind the natural sepiolite to 50 mesh, pass through 50 sieves, put the natural sepiolite powder and water into deionized water at a mass ratio of 1:25, and then stir evenly to obtain a sepiolite suspension. Then absolute ethanol (mass ratio of absolute alcohol to sepiolite is 1:2.3) and 3-mercaptopropyltrimethoxysilane (mass ratio of 3-mercaptopropyltrimethoxysilane to sepiolite is 1 : 4.7) mixed with each other evenly to make a mixing ...

Embodiment 3

[0051] The suspended assembled floor provided in this embodiment includes, by mass percentage, 46% of modified sepiolite, 22% of SEBS, 30% of nano filler, and the balance is polypropylene.

[0052] Wherein, the SEBS is the YH-511 SEBS produced by Baling Petrochemical;

[0053] The model produced by Jing Kelin in the nano-filler is a novel inorganic filler of PO789;

[0054] Described polypropylene is No. 150 PP produced by Baling Petrochemical;

[0055] The preparation method of described modified sepiolite is as follows:

[0056] Crush and grind the natural sepiolite to 50 mesh, pass through 50 sieves, put the natural sepiolite powder and water into deionized water at a mass ratio of 1:25, and then stir evenly to obtain a sepiolite suspension. Then absolute ethanol (mass ratio of absolute alcohol to sepiolite is 1:2.3) and 3-mercaptopropyltrimethoxysilane (mass ratio of 3-mercaptopropyltrimethoxysilane to sepiolite is 1 : 4.7) mixed with each other evenly to make a mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com