A kind of preparation method of tin oxide nanosheet array supercapacitor cathode material

A nanosheet array and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of hindering high-performance pseudocapacitive electrode materials, poor capacitor rate performance, and nanostructure agglomeration. Good for rapid transfer, high capacitance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the alloying enhanced oxygen-deficient tin oxide nanosheet array supercapacitor positive electrode material proposed by the present invention comprises the following steps and contents:

[0039] (1) First put 40-80mL deionized water in a beaker, then dissolve 1.5-2.3g stannous chloride dihydrate and 2.5-3.5g trisodium citrate in it, and stir magnetically for 20-40min to obtain a uniform, Stable milky white suspension, then slowly add absolute ethanol into the beaker according to the volume ratio of absolute ethanol: deionized water 3:1-1:5, and continue to stir for 30-60min to obtain a slightly white precursor solution, set aside .

[0040] (2) Transfer the precursor solution to the polytetrafluoroethylene lining of the autoclave, and fix the clean foamed nickel sheet vertically in the reactor, and completely immerse it in the precursor solution. Then, after the reaction kettle is sealed and assembled, it is placed in an oven for heat preserva...

Embodiment

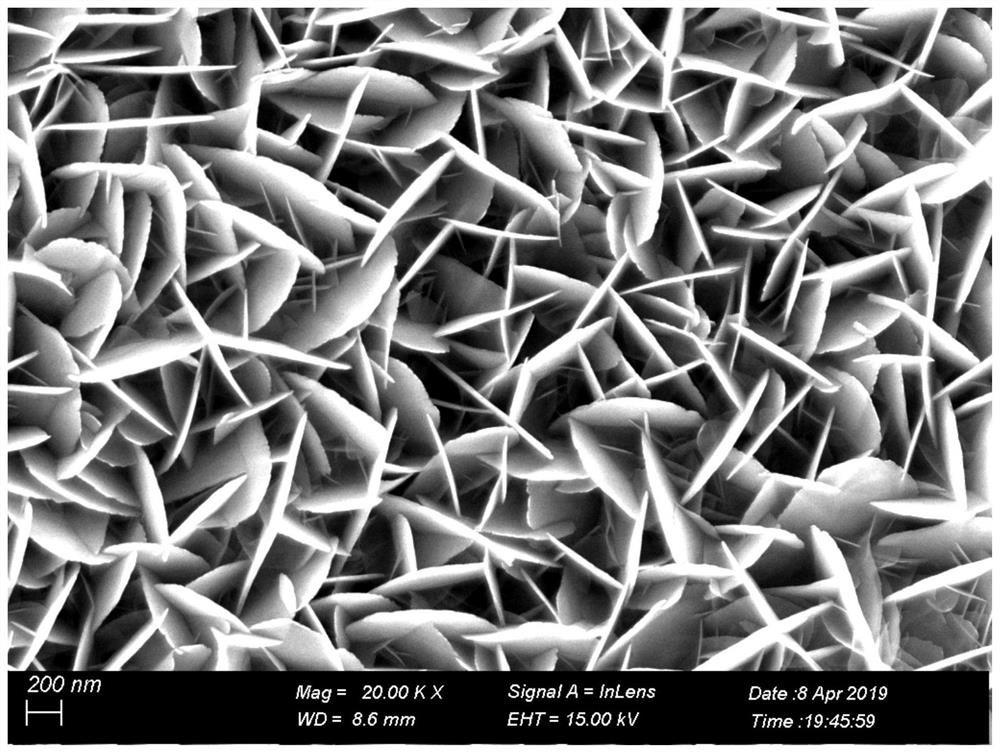

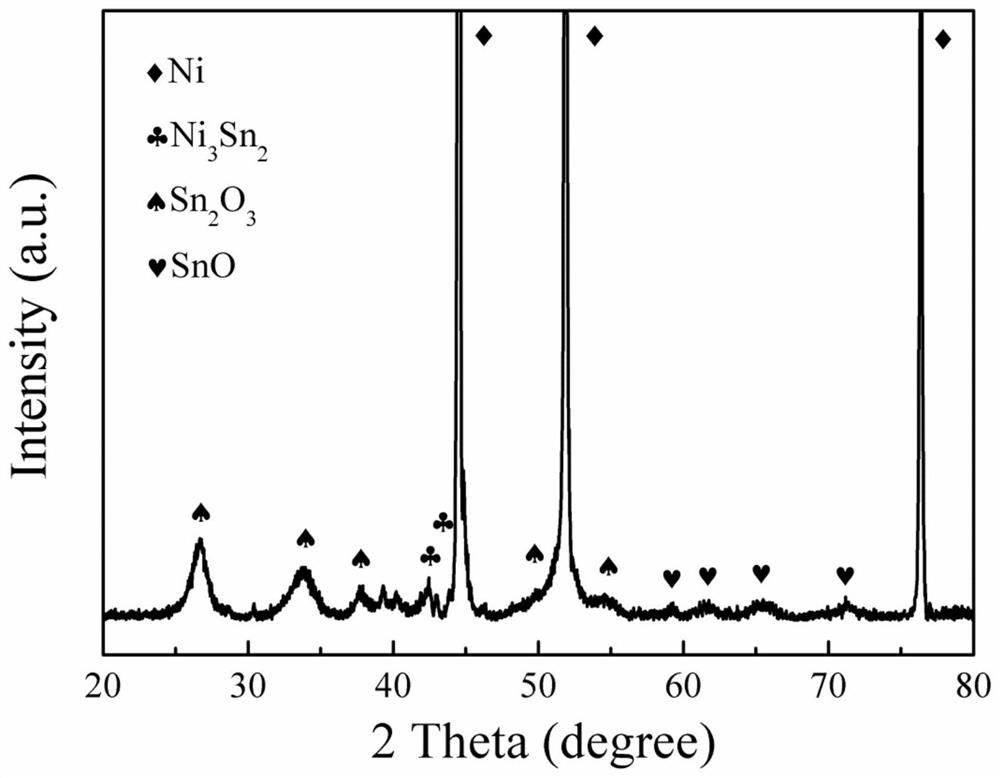

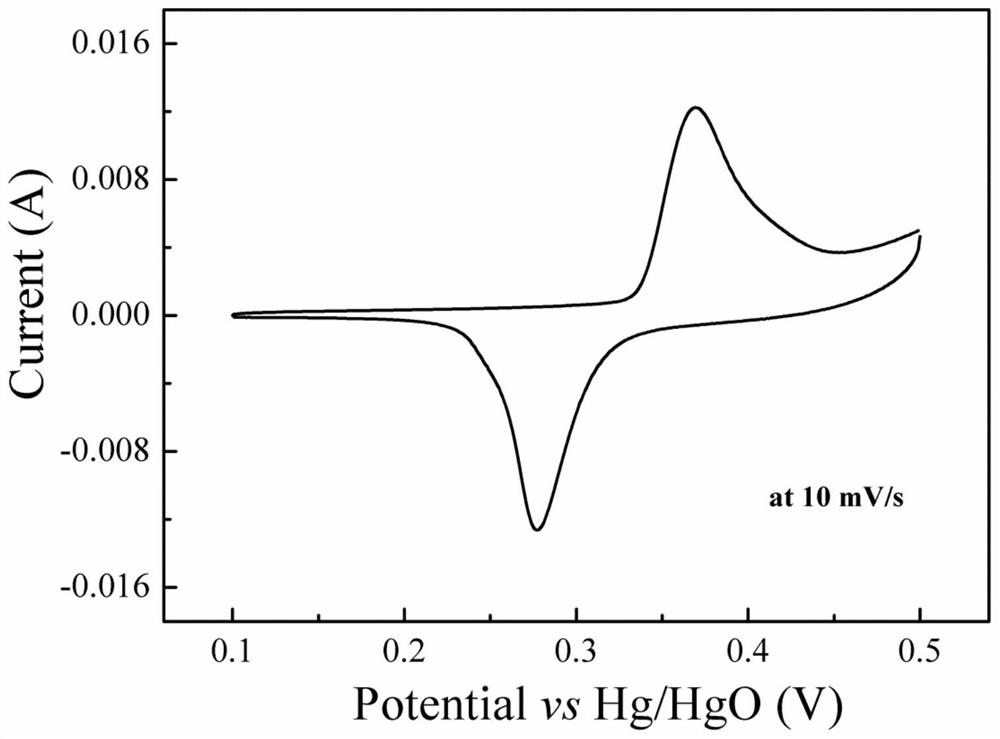

[0048] Embodiment: first fill in 40mL deionized water in the beaker, then 2.073g tin protochloride dihydrate and 2.971g trisodium citrate are dissolved therein, obtain uniform, stable milky white suspension after magnetic stirring 30min, again Slowly add 40 mL of absolute ethanol into the beaker, and continue stirring for 30 min to obtain a slightly white precursor solution. Then, the precursor solution was transferred to the polytetrafluoroethylene liner of a 100mL autoclave, and a piece of 3.5cm×3.5cm clean nickel foam was vertically fixed in the reactor and completely immersed in the in the precursor solution. Then, after the reaction kettle was sealed and assembled, it was placed in an oven and kept at 180° C. for 12 hours. After naturally cooling to room temperature, open the reaction kettle, take out the nickel foam sample, rinse it with deionized water for 5 times, and place it in an oven at 100°C for 4 hours to dry it. Then, place the nickel foam sample obtained at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com