Method of preparing polyacrylonitrile-based carbon raw fibers by dry-wet method

A polyacrylonitrile-based carbon fiber, dry and wet technology, applied in wet spinning, fiber chemical characteristics, stretch spinning, etc., can solve the problem of easily disturbed coagulation bath level, inconsistent residence time, and insufficient coagulation of silk strands. It can solve the problem of atmospheric disturbance of the coagulation bath, improve the uniformity and adhesion problems, and facilitate stable and continuous effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A dry-wet method for preparing polyacrylonitrile-based carbon fiber precursors, comprising the following steps:

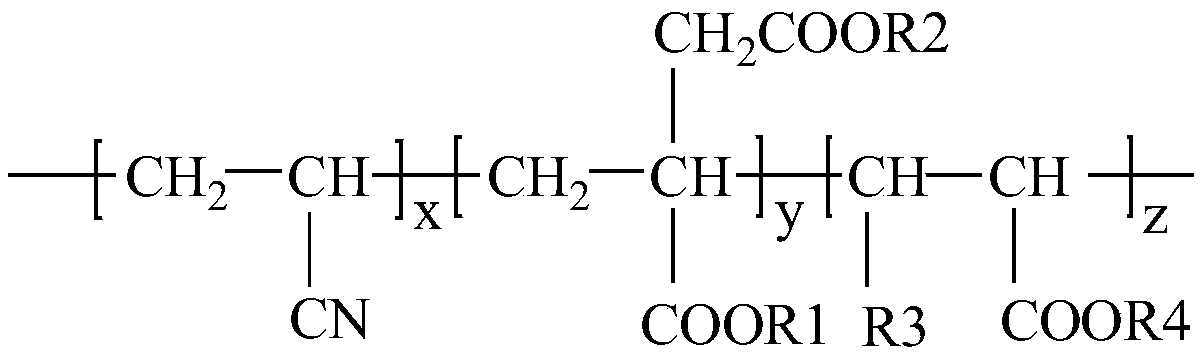

[0033] (1) Preparation of spinning stock solution: spinning stock solution is composed of acrylonitrile copolymer and solvent dimethyl sulfoxide, wherein the acrylonitrile copolymer is a binary copolymer of acrylonitrile and itaconic acid, and the structural formula is as follows:

[0034]

[0035] In the formula: R1 is H; R2 is H; R 3 for CH 3 ; R4 is CH 3 CH 2 ;x=99.5mol%, y=0.5mol%, z=0;

[0036] The dynamic viscosity of the above-mentioned spinning dope is 50 Pa·s, the intrinsic viscosity of the acrylonitrile copolymer is 1.6 dL / g, and the temperature is 80°C.

[0037] (2) Spinning: the spinning dope is sent to the spinneret assembly through a primary filter and a secondary filter by a metering pump and a booster pump. The jacket water of the spinneret assembly is kept at a constant temperature of 30°C, and the distance between the spinneret and t...

Embodiment 2

[0048] A dry-wet method for preparing polyacrylonitrile-based carbon fiber precursors, comprising the following steps:

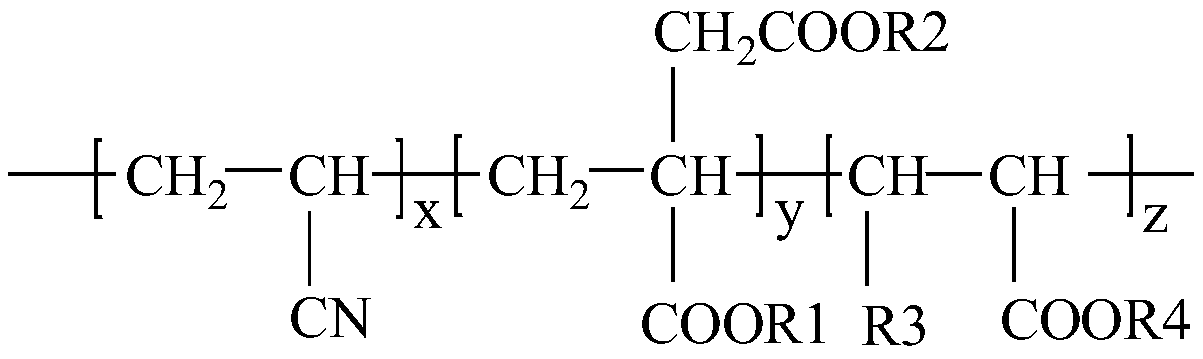

[0049] (1) Preparation of spinning stock solution: spinning stock solution is composed of acrylonitrile copolymer and solvent dimethyl sulfoxide, wherein the acrylonitrile copolymer is a terpolymer of acrylonitrile, itaconic acid derivatives, and acrylic acid derivatives, and the structural formula As follows:

[0050]

[0051] In the formula: R1 is NH 4 ; R2 is CH 3 CH 2 ; 3 Is H; R4 is H; x=97.6mol%, y=0.4mol%, z=2mol%;

[0052] The dynamic viscosity of the above-mentioned spinning dope is 250 Pa·s, the intrinsic viscosity of the acrylonitrile copolymer is 5 dL / g, and the temperature is 45°C.

[0053] (2) Spinning: The spinning dope is sent to the spinneret assembly through a primary filter and a secondary filter by a metering pump and a booster pump. The jacket water of the spinneret assembly is kept at a constant temperature of 50°C, and the dist...

Embodiment 3

[0064] A dry-wet method for preparing polyacrylonitrile-based carbon fiber precursors, comprising the following steps:

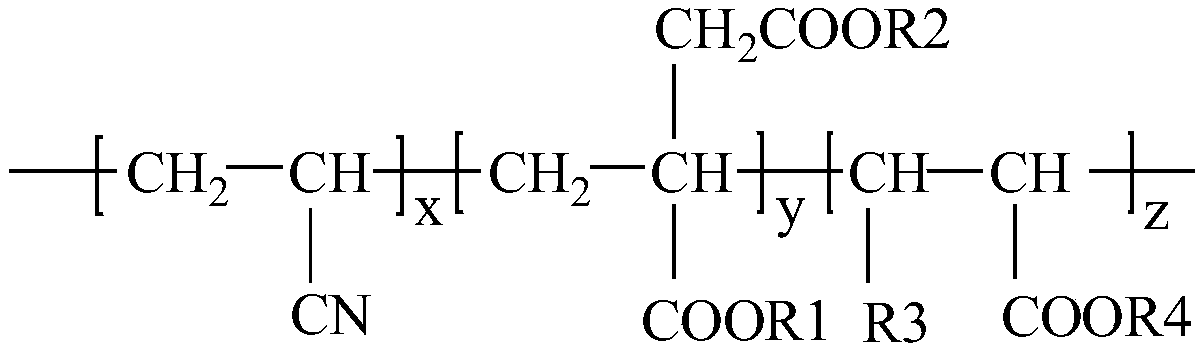

[0065] (1) Preparation of spinning stock solution: spinning stock solution is composed of acrylonitrile copolymer and solvent dimethyl sulfoxide, wherein the terpolymer of acrylonitrile copolymer acrylonitrile and itaconic acid derivatives and acrylic acid derivatives has the following structural formula Shown:

[0066]

[0067] In the formula: R1 is H; R2 is CH 3 ; 3 for CH 3 ; R4 is CH3; x=90mol%, y=9mol%, z=1mol%;

[0068] The dynamic viscosity of the above-mentioned spinning dope is 150 Pa·s, the intrinsic viscosity of the acrylonitrile copolymer is 3.5 dL / g, and the temperature is 55°C.

[0069] (2) Spinning: the spinning dope is sent to the spinneret assembly through a primary filter and a secondary filter by a metering pump and a booster pump. The jacket water of the spinneret assembly is kept at a constant temperature of 40°C, and the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com