Antistatic self-recovery triple interpenetrating network silicon hydrogel and preparation method thereof

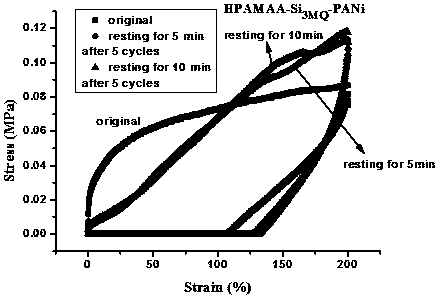

A technology of silicon hydrogel and interpenetrating network, which is applied in the field of antistatic self-recovery triple interpenetrating network silicon hydrogel and its preparation, can solve the problem of self-recovery performance and antistatic performance of silicon-containing polymers, which are easy to accumulate static electricity and prepare The process is complex and cannot have mechanical and mechanical properties at the same time, so as to achieve the effects of excellent self-recovery performance, excellent anti-fatigue performance, and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of antistatic self-restoring triple interpenetrating network silicon hydrogel, comprising the following steps:

[0042] 1) Add 24mL deionized water to a 100mL beaker, add 3.75g acrylamide AM, 0.47g acrylic acid AA, 2g cetyltrimethylammonium bromide and 0.31g octadecyl methacrylate, at a certain temperature Stir to make it dissolve, and then add 2mL of ethanol, 1g of hexamethyldisiloxane, 3.25g of ethyl orthosilicate and 3mL of concentrated hydrochloric acid in sequence after stirring evenly, and continue stirring. Dissolve 20 mg of potassium persulfate in 1 mL of deionized water and add it to the above solution, then transfer the above prepared solution to a self-made glass mold, and polymerize at 70 °C for 24 hours to obtain a double network silicone hydrogel HPAMAA -Si 3MQ Dumbbell-shaped spline (3 represents the amount of hydrochloric acid added, M and Q refer to hexamethyldisiloxane and tetraethylorthosilicate, respectively).

[0043] 2) Take ...

Embodiment 2

[0050] A preparation method of antistatic self-restoring triple interpenetrating network silicon hydrogel, comprising the following steps:

[0051] 1) Add 24mL deionized water to a 100mL beaker, add 3.75g acrylamide AM, 0.47g acrylic acid AA, 2g cetyltrimethylammonium bromide and 0.31g octadecyl methacrylate, at a certain temperature Stir to dissolve. After stirring evenly, add 2 mL of ethanol, 1 g of hexamethyldisiloxane, 3.25 g of ethyl orthosilicate and 3 mL of concentrated hydrochloric acid in sequence, and continue stirring. Dissolve 20 mg of potassium persulfate in 1 mL of deionized water and add to the above solution. Transfer the above-prepared solution to a self-made glass mold, and polymerize at 70°C for 24 hours to obtain a double-network silicon hydrogel HPAMAA-Si 3MQ Dumbbell-shaped spline (3 represents the amount of hydrochloric acid added, M and Q refer to hexamethyldisiloxane and tetraethylorthosilicate, respectively).

[0052] 2) Take 4 mL of 50% phytic aci...

Embodiment 3

[0061] A preparation method of antistatic self-restoring triple interpenetrating network silicon hydrogel, comprising the following steps:

[0062] 1) Add 24mL deionized water to a 100mL beaker, add 3.75g acrylamide AM, 0.47g acrylic acid AA, 2g cetyltrimethylammonium bromide and 0.31g octadecyl methacrylate, at a certain temperature Stir to dissolve. After stirring evenly, add 2 mL of ethanol, 1 g of hexamethyldisiloxane, 3.25 g of ethyl orthosilicate and 3 mL of concentrated hydrochloric acid in sequence, and continue stirring. Dissolve 20 mg of potassium persulfate in 1 mL of deionized water and add to the above solution. Transfer the above-prepared solution to a self-made glass mold and polymerize at 70°C for 24 hours to obtain a hydrophobic silicon hydrogel HPAMAA-Si 3MQ Dumbbell-shaped spline (3 represents the amount of hydrochloric acid added, M and Q refer to hexamethyldisiloxane and tetraethylorthosilicate, respectively).

[0063] 2) Take 4 mL of 50% phytic acid aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com