A kind of preparation method of ultra-low dielectric constant glass microsphere/resin composite material

A resin composite material and ultra-low dielectric constant technology, applied in the field of material science, can solve the problems of high dielectric constant and unstable performance, and achieve the effect of improving performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

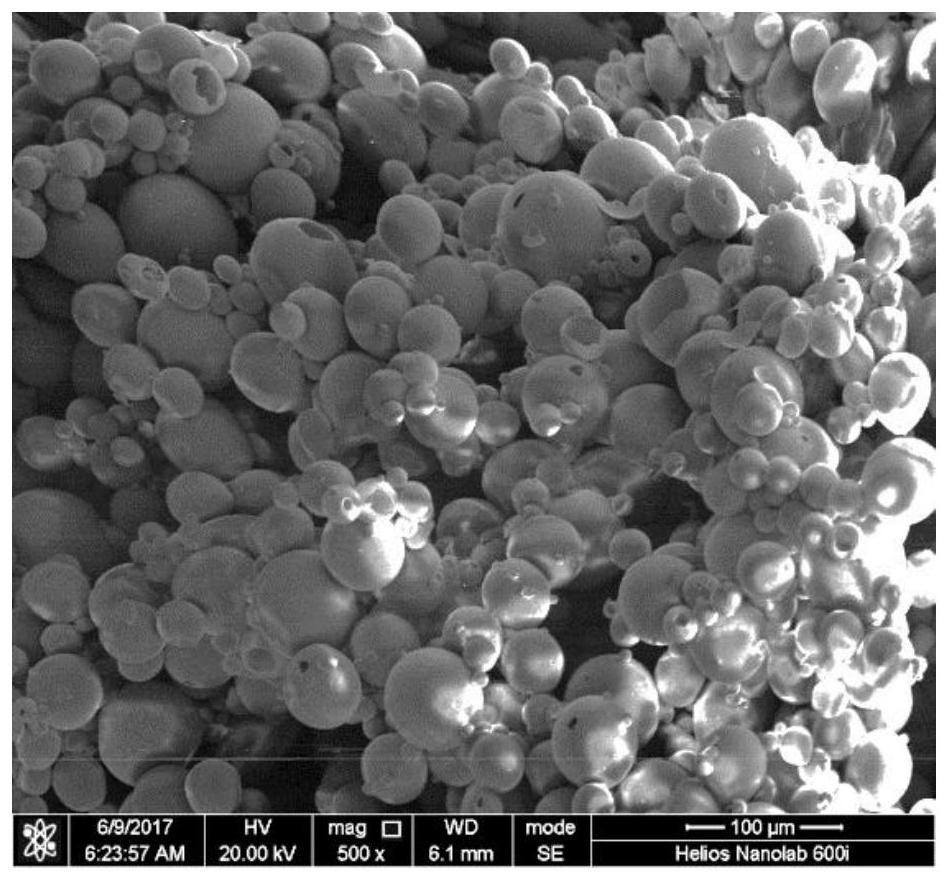

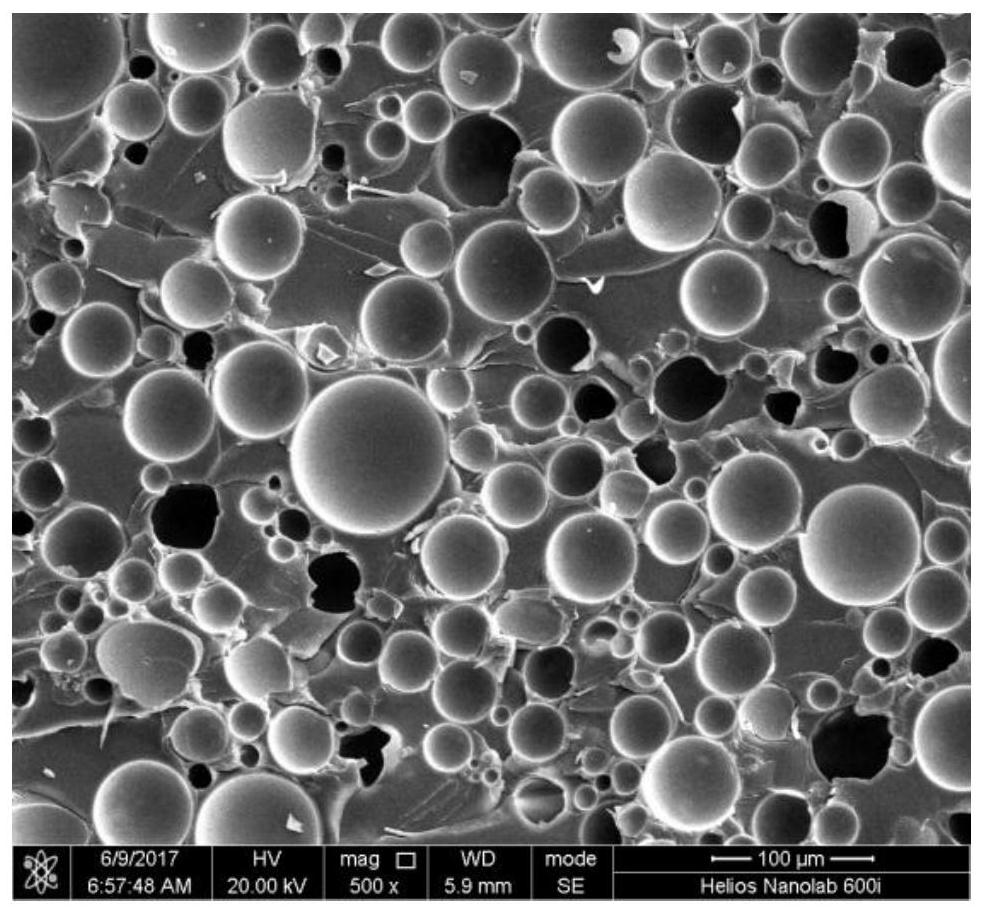

Image

Examples

Embodiment 1

[0023] In the preparation method provided in this embodiment, the dielectric constant of the glass microsphere / resin composite material is 1.85 to 2.93, and the specific steps are as follows:

[0024] Step 1. Add 0.2-0.4wt% thickener polyacrylamide (PAM), 8-12wt% monomer acrylamide (AM) and 0.8-1.2wt% cross-linking agent N-N' to deionized water - Methylenebisacrylamide (MBAM), configured as a solvent for water-based slurry;

[0025] Step 2, adding glass microspheres into the above solvent, wherein the volume fraction of glass microspheres in the slurry is 15-55vol%, and stirring for 1-2 hours;

[0026] Step 3, add initiator ammonium persulfate (APS) and catalyst tetramethylethylenediamine (TEMED) in slurry, the mass ratio of initiator and monomer is 1:(3~10), the ratio of catalyst to monomer The mass ratio is 1:(30-200), continue to stir for 2 minutes; vacuum defoam the slurry, and pour it into the mold for cross-linking and solidification;

[0027] Step 4: Submerge the soli...

Embodiment 2

[0033] In the preparation method provided in this example, the dielectric constant of the glass microsphere / resin composite material is 2.93, and the specific steps are as follows:

[0034] Step 1. Add 0.4wt% thickener polyacrylamide (PAM), 12wt% monomeric acrylamide (AM) and 1.2wt% crosslinker N-N'-methylenebispropylene to deionized water Amide (MBAM), configured as a solvent for water-based slurry;

[0035] Step 2, glass microspheres are added in the above-mentioned solvent, wherein the volume fraction of glass microspheres in the slurry is 15vol%, stir for 2 hours, then add initiator and catalyst, wherein the initiator is ammonium persulfate (APS), initiate The mass ratio of agent and monomer is 1:5, and catalyzer is tetramethylethylenediamine (TEMED), and the mass ratio of catalyzer and monomer is 1:100, continues to stir 2 minutes;

[0036] Step 3. Vacuum defoam the above slurry, inject it into the mold for cross-linking and solidification; submerge the solidified blank ...

Embodiment 3

[0043] The difference between this embodiment and embodiment 2 is that the resin monomer in step five is BT monomer, and the others are the same as in embodiment 2. The prepared ceramics have a dielectric constant of 2.91 and a dielectric loss of 4.87×10 -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com