Oxygen separation device and process

A separation device and process technology, applied in the application field of mixed conductor oxygen-permeable membrane, can solve the problems of large power plant energy consumption, energy consumption reduction, low purity, etc., achieve good economic and social effects, compact and reasonable structure, and widely used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

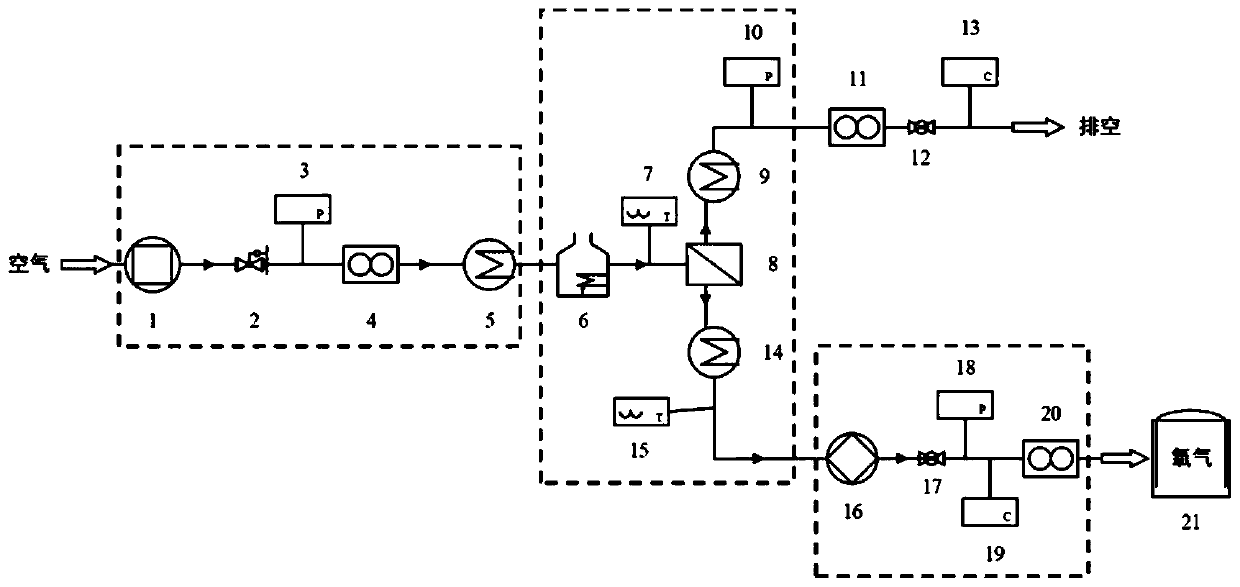

[0018] Such as figure 1 As shown, an oxygen separation device is characterized in that the device includes an air pressurization system, an oxygen separation system, a vacuum system and an air storage tank, wherein the air pressurization system is successively composed of an air compressor 1 through a pressure reducing valve 2, the first A pressure detector 3, the first flow detector 4 are connected with the first heat exchanger 5, and the feed side of the air compressor 1 is communicated with the atmosphere; the oxygen separation system consists of a heater 6, a membrane module 8, and a second heat exchanger 9. The third heat exchanger 14 is composed of one side of the heater 6 connected with the first heat exchanger 5, and the other side is connected with the membrane module 8 through the first temperature detector 7, and one side of the membrane module 8 is connected with the second heat exchanger 9, connected to the exhaust pipe through the second pressure detector 10, the...

Embodiment 2

[0021] The oxygen separation device and separation process are the same as in Example 1. After the air in the atmosphere is compressed by the air compressor 1 in the air pressurization system, it enters the membrane module 8 and the heater 6 of the oxygen separation system to be heated, and the air compressor The outlet pressure is 5atm, and the feed air is heated by the thermal energy of evacuating oxygen-depleted air and product oxygen. The first heat exchanger 5, the second heat exchanger 9, and the third heat exchanger 14 adopt partition wall heat exchangers, and exchange heat through a mixture of heat transfer medium water and ethanol. The energy required by the heater 6 and the first heat exchanger 5, the second heat exchanger 9, and the third heat exchanger 14 is supplemented by electricity, and the oxygen that is separated by the multi-channel mixed conductor oxygen-permeable membrane in the membrane module 8 is The temperature is controlled at 600°C. Among them, the ...

Embodiment 3

[0023] The oxygen separation device and separation process are the same as in Example 1. After the air in the atmosphere is compressed by the air compressor 1 in the air pressurization system, it enters the membrane module 8 and the heater 6 of the oxygen separation system to be heated, and the air compressor The outlet pressure is 30atm, and the heat energy of boiler exhaust gas and steam is used to heat the feed air. The first heat exchanger 5, the second heat exchanger 9, and the third heat exchanger 14 adopt hybrid heat exchangers, and exchange heat through a mixture of heat transfer medium ethylene glycol and oil. The energy required by the heater 6 and the first heat exchanger 5, the second heat exchanger 9, and the third heat exchanger 14 is supplemented by steam, and the temperature of the oxygen separated by the multi-channel mixed conductor oxygen-permeable membrane in the membrane assembly 8 Controlled at 1050°C. Among them, the multi-channel mixed conductor oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com