Crane operation mechanism rail gnawing prevention device, crane operation mechanism rail gnawing prevention deviation rectification control system, and crane operation mechanism rail gnawing prevention deviation rectification control method

A technology of operating mechanism and control system, applied in the direction of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problems of not easy to replace the guide wheel, large impact force, sudden contact with the side of the rail, etc. Economic and safety benefits, the effect of reducing lateral frictional resistance and eliminating major safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

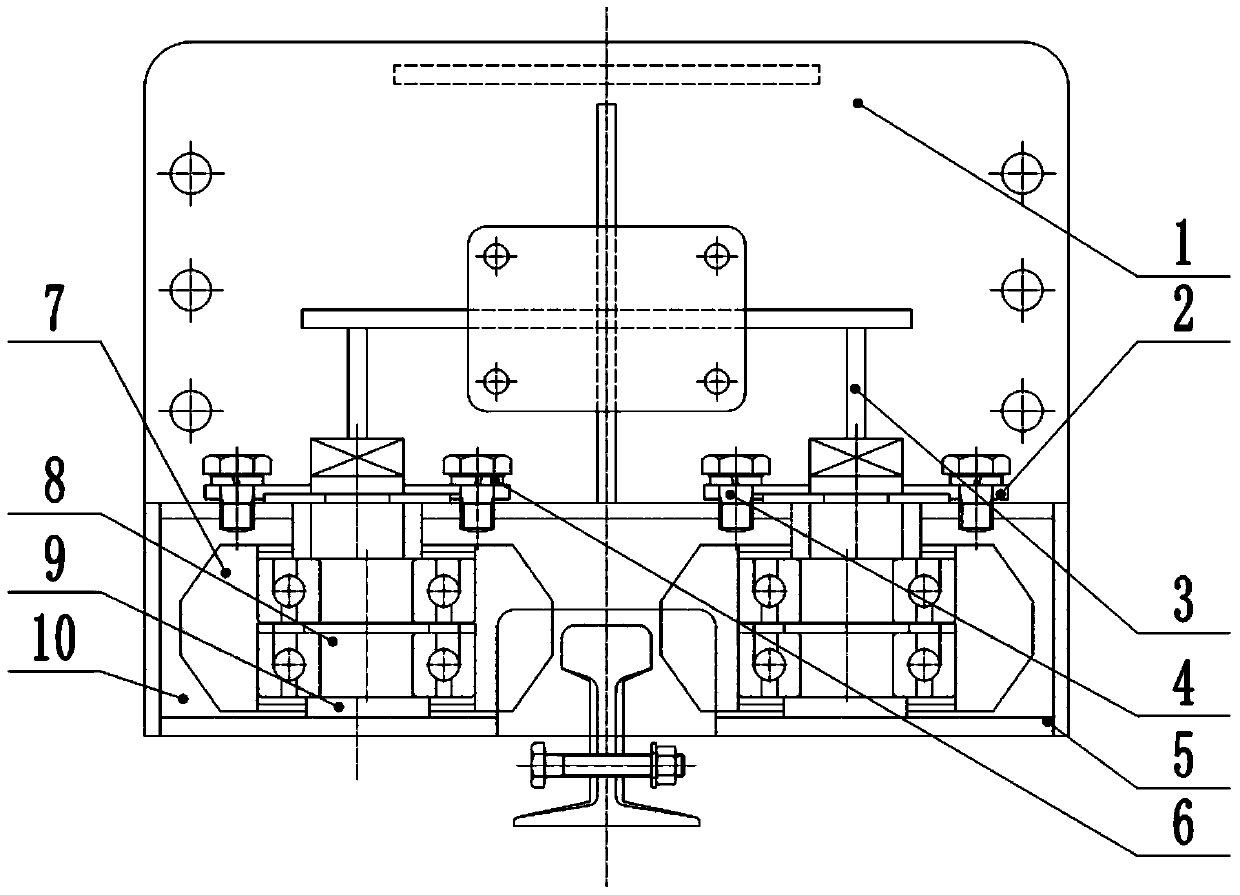

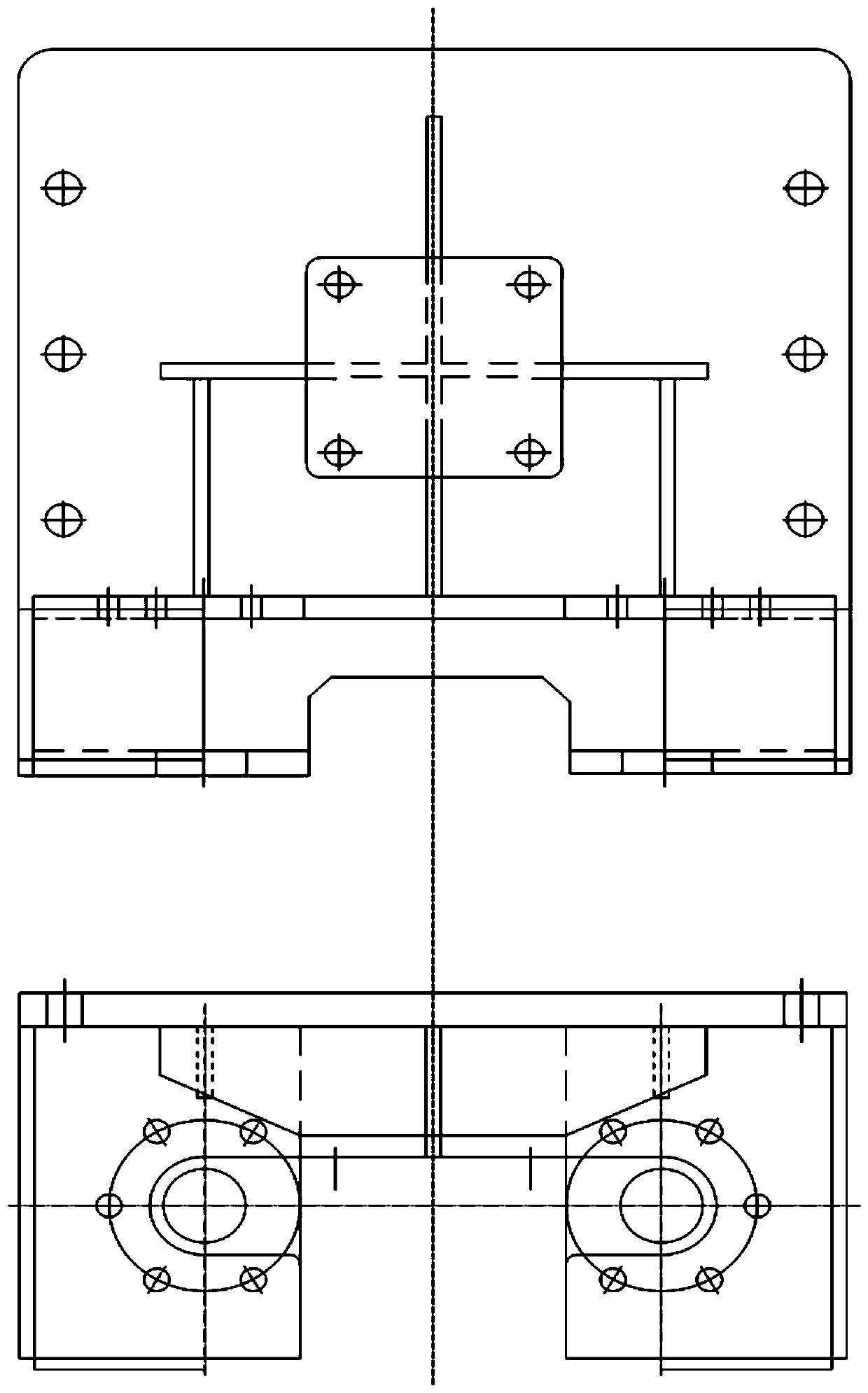

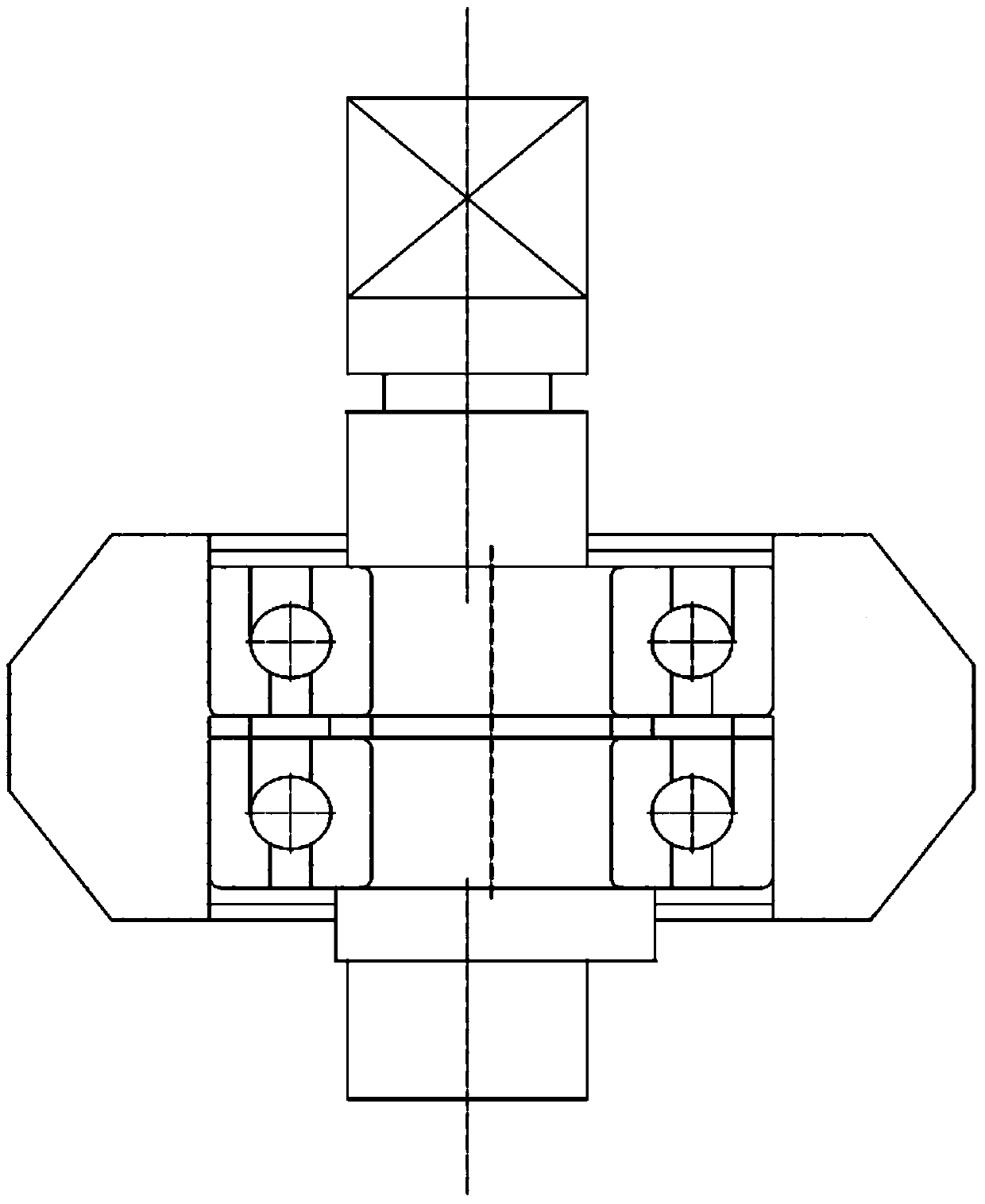

[0051] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0052] In the prior art, the rail gnawing phenomenon of the crane operating mechanism (cart or trolley) cannot be solved, without installing the side guide wheel assembly on the underside of the wheel rim, using the side guide wheel to withstand the side of the rail and not making the crane wheel There is a small gap between the wheel rim and the side of the rail, which causes wear between the wheel rim and the track during the operation of the wheel set. The stability of the crane is poor during operation, and the lateral frictional resistance of the crane cannot be reduced, so that the friction between the small wheel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com