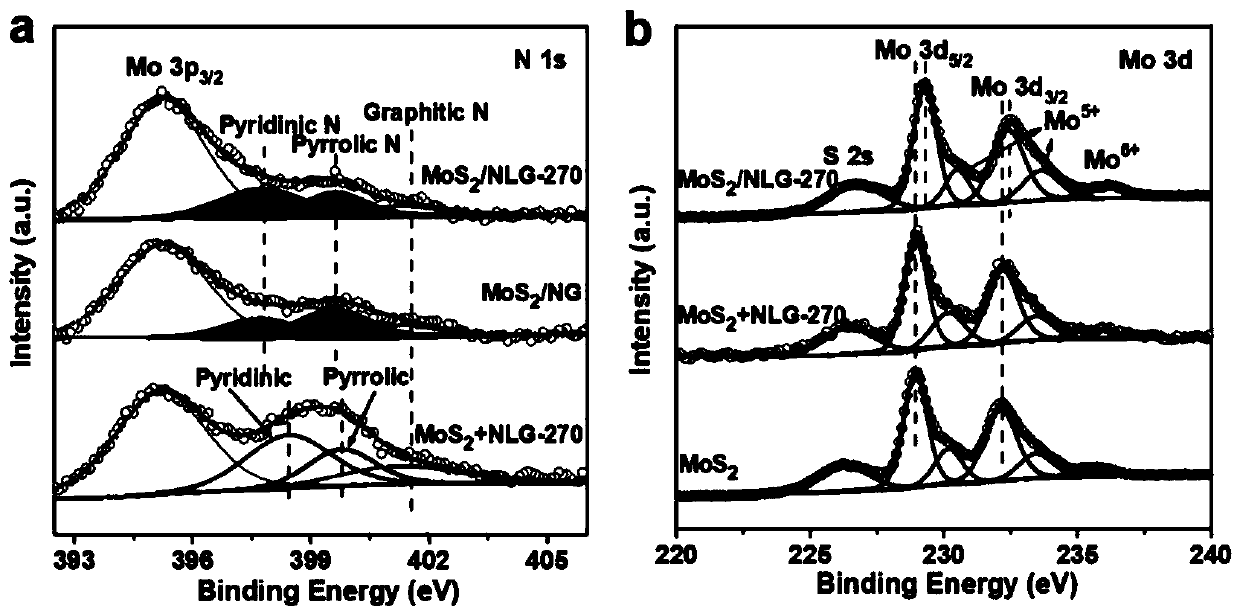

Preparation method of mesoporous nitrogen-doped graphene-loaded molybdenum disulfide synthesized by laser irradiation and application of mesoporous nitrogen-doped graphene-loaded molybdenum disulfide in electrocatalytic hydrogen production

A nitrogen-doped graphene, laser irradiation technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve problems such as the inability to effectively control the content of carbon pyridine nitrogen metal bonds, and achieve easy control and operation. The effect of convenient and efficient catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Put 10 mg of graphene oxide in 30 mL of absolute ethanol (purity is analytically pure), ultrasonically crush to obtain a uniformly dispersed suspension, pour the suspension into a 50 mL Erlenmeyer flask, and control the magnetic stirring speed at 400 rpm, and irradiated with 270mJ nanosecond parallel pulsed laser for 25min in an ice-water bath to obtain graphene oxide after laser irradiation.

[0037] (2) After the graphene oxide after the laser irradiation of the step (1) gained is centrifuged (18000 rpm) for 15 minutes, add deionized water to clean the precipitate, centrifuge at a speed of 18000 rpm for 15 minutes, and then Add deionized water and centrifuge at 18,000 rpm for 15 minutes, repeat the operation until the product smells odorless, and then freeze-dry the product with a lyophilizer.

[0038] (3) Graphene oxide and 20 mg ammonium tetrathiomolybdate after freeze-drying obtained in step (2) are dispersed in 10 mL of N,N-dimethylformamide, then 200 mg of ur...

Embodiment 2

[0043] (1) Put 7.5mg of graphene oxide in 30mL of absolute ethanol (purity is analytically pure), ultrasonically crush to obtain a uniformly dispersed suspension, and ultrasonically crush to obtain a uniformly dispersed suspension, pour the suspension into 50mL The Erlenmeyer flask, the magnetic stirring speed is controlled at 300 rpm, and irradiated with 177mJ nanosecond parallel pulsed laser for 30min in an ice-water bath to obtain graphene oxide after laser irradiation.

[0044] (2) After the graphene oxide after the laser irradiation of the step (1) gained is centrifuged (15000 rpm) for 20 minutes, add deionized water to clean the precipitate, centrifuge at a speed of 15000 rpm for 20 minutes, and then Add deionized water and centrifuge at 15,000 rpm for 20 minutes, repeat the operation until the product smells odorless, and then freeze the product with a lyophilizer.

[0045] (3) Graphene oxide and 15 mg ammonium tetrathiomolybdate after the lyophilized laser irradiation ...

Embodiment 3

[0050] (1) Put 9.5 mg of graphene oxide in 30 mL of absolute ethanol (purity is analytically pure), ultrasonically crush to obtain a uniformly dispersed suspension, ultrasonically to obtain a uniformly dispersed suspension, and ultrasonically to obtain a uniformly dispersed suspension For turbid liquid, pour the suspension into a 50mL Erlenmeyer flask, control the magnetic stirring speed at 400 rpm, and irradiate with 220mJ nanosecond parallel pulsed laser in an ice-water bath for 28min to obtain graphene oxide after laser irradiation.

[0051] (2) After the graphene oxide after the laser irradiation of the step (1) gained is centrifuged (16000 rpm) for 20 minutes, add deionized water to clean the precipitate, centrifuge at a speed of 16000 rpm for 20 minutes, and then Add deionized water and centrifuge at 16,000 rpm for 20 minutes, repeat the operation until the product smells odorless, and then freeze-dry the product with a lyophilizer.

[0052] (3) Graphene oxide and 19 mg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com