Silicotungstic acid intercalated multi-component hydrotalcite-like lightweight thermal insulation material and preparation method thereof

A lightweight thermal insulation and hydrotalcite technology, applied in the field of biomass foam materials, can solve the problems of low strength and thermal difference, and achieve the effects of low thermal conductivity, reduced heat and smoke release, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a silicotungstic acid intercalated multi-element hydrotalcite / nanocellulose lightweight foam thermal insulation material in a specific embodiment of the present invention comprises the following steps:

[0037] (1) Prepare multi-component hydrotalcite-like precursors by co-precipitation method;

[0038] (2) modifying the hydrotalcite-like precursor in step (1) by an ion exchange method to obtain silicotungstic acid-multiple hydrotalcite-like;

[0039] (3) Mix silicotungstic acid obtained in step (2) with additives such as multi-component hydrotalcite, nanocellulose, and adhesive, and freeze-dry to obtain a lightweight foam material intercalated with silicotungstic acid and multi-component hydrotalcite nanocellulose .

[0040] The multi-element hydrotalcites are binary, ternary, quaternary or quinary hydrotalcites formed by divalent metal ions and trivalent metal ions, wherein the divalent metal ions M 2+ for Mg 2+ , Zn 2+ 、Ni 2+ , Ca 2+ , Fe...

Embodiment 1

[0059] (1) Press n(Zn 2+ ) / n(Mg 2+ ) / n(Al 3+ )=2:1:1 Weigh Zn(NO 3 ) 2 .9H 2 O, Mg(NO 3 ) 2 .6H 2 O and Al(NO 3 ) 3 .9H 2 O, adjust the pH value to 7.0, react at 70°C for 12h, and prepare ZnMgAl-NO by co-precipitation method 3 -LDHs.

[0060] (2) press m 主体 / m [SiW12O40]3 -=1:2 Accurately weigh a certain mass H 3 SiW 12 o 40 Dissolve in deionized water, neutralize with quantitative NaOH to obtain sodium silicotungstate solution. in N 2 Under the atmosphere, add the sodium silicotungstate solution drop by drop to the Zn / Al+-NO 3 - Stir vigorously in the LDHs main body slurry; make the reaction solution react at a set temperature of 60° C. for 14 hours. After repeated washing with deionized water, dry at 50°C under normal pressure for 24 hours to obtain ZnMgAl-SiW 12 o 40 -LDHs white solid.

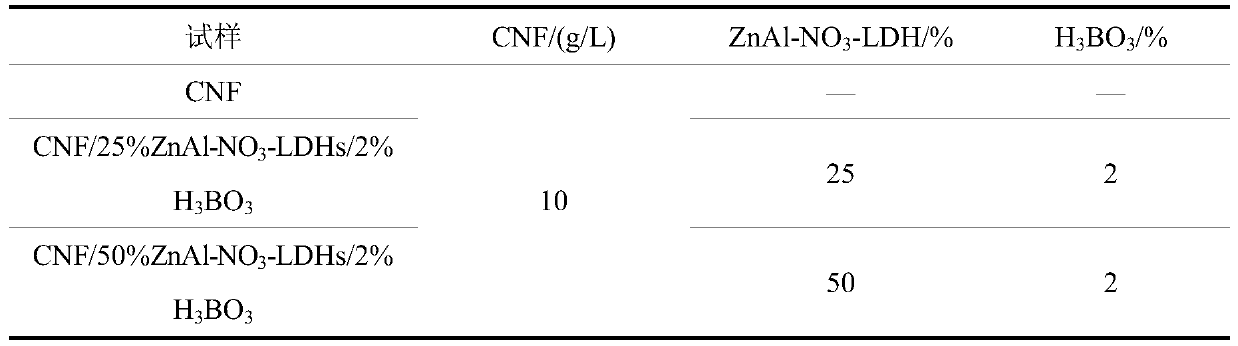

[0061] (3) According to the dry weight mass percentage ratio of Table 2 (CNF+ZnMgAl-SiW 12 o 40 -LDHs+H 3 BO 3 Total 100%), the ZnMgAl-SiW 12 o 40 - LDHs slurry ...

Embodiment 2

[0067] (1) Press n(Zn 2+ ) / n(Mg 2+ ) / n(Ca 2+ ) / n(Al 3+ )=1:1:1:1 Weigh Zn(NO 3 ) 2 .9H 2 O, Mg(NO 3 ) 2 .6H 2 O, Ca(NO 3 ) 2 .4H 2 O, Al(NO 3 ) 3 .9H 2 O, adjust the pH value to 7.0, react at 70°C for 12h, and prepare ZnMgCaAl-NO by co-precipitation method 3 -LDHs.

[0068] (2) press m 主体 / m [SiW12O40]3 -=1:2 Accurately weigh a certain mass H 3 SiW 12 o 40 Dissolve in deionized water, neutralize with quantitative NaOH to obtain sodium silicotungstate solution. in N 2 Under the atmosphere, add the sodium silicotungstate solution drop by drop to the Zn / Al+-NO 3 - Stir vigorously in the LDHs main body slurry; make the reaction solution react at a set temperature of 60° C. for 14 hours. After repeated washing with deionized water, dry at 50°C under normal pressure for 24 hours to obtain ZnMgCaAl-SiW 12 o 40 -LDHs white solid.

[0069] (3) According to the dry weight mass percentage ratio of Table 3, the ZnMgCaAl-SiW 12 o 40 - LDHs slurry and CNF are mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com