Ultra-fine montmorillonite-based core-shell structure anti-explosion agent and preparation method thereof

A technology of montmorillonite and shell structure, which is used in earth-moving drilling, mining equipment, dust prevention, etc., can solve the problem of poor explosion suppression effect, and achieve the effect of excellent explosion suppression performance, low process energy consumption and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The raw materials of the superfine montmorillonite-based core-shell structure antiknock agent in this embodiment are: 6 parts of montmorillonite, 3 parts of ammonium dihydrogen phosphate, and 1 part of hydrophobic fumed silica.

[0041] Its preparation method is as follows:

[0042] Step 1: Ball mill the montmorillonite and ammonium dihydrogen phosphate for 15 minutes respectively, the ball-to-material ratio is 2.5:1, and the frequency is 40Hz. After ball milling, put it into a drying oven to dry for 8 hours, and control the temperature to be 80 degrees Celsius.

[0043]Step 2: Dissolve 43.9g of dried ammonium dihydrogen phosphate into 100mL of distilled water; under magnetic stirring, disperse 87.8g of dried montmorillonite into 300mL of absolute ethanol, and then slowly pour saturated phosphoric acid After the addition of ammonium dihydrogen aqueous solution, continue magnetic stirring for 4 hours, then age and precipitate for 4 hours, filter out the precipitate, and...

Embodiment 2

[0049] The raw materials of the superfine montmorillonite-based core-shell structure antiknock agent in this embodiment are: 6 parts of montmorillonite, 3 parts of sodium bicarbonate, and 1 part of hydrophobic fumed silica.

[0050] Its preparation method is as follows:

[0051] Step 1: Ball mill the montmorillonite and sodium bicarbonate for 12 minutes respectively, the ball-to-material ratio is 3:1, and the frequency is 42.5Hz. After ball milling, put it into a drying oven to dry for 8 hours, and control the temperature at 60 degrees Celsius.

[0052] Step 2: Dissolve 22.5g of dried sodium bicarbonate into 200mL of distilled water; under magnetic stirring, disperse 45g of dried montmorillonite into 400mL of absolute ethanol, and then slowly pour saturated sodium bicarbonate After the addition of the aqueous solution, continue magnetic stirring for 4 hours, then age and precipitate for 4 hours, filter out the precipitate, and dry at 30 degrees Celsius for 8 hours to obtain a...

Embodiment 3

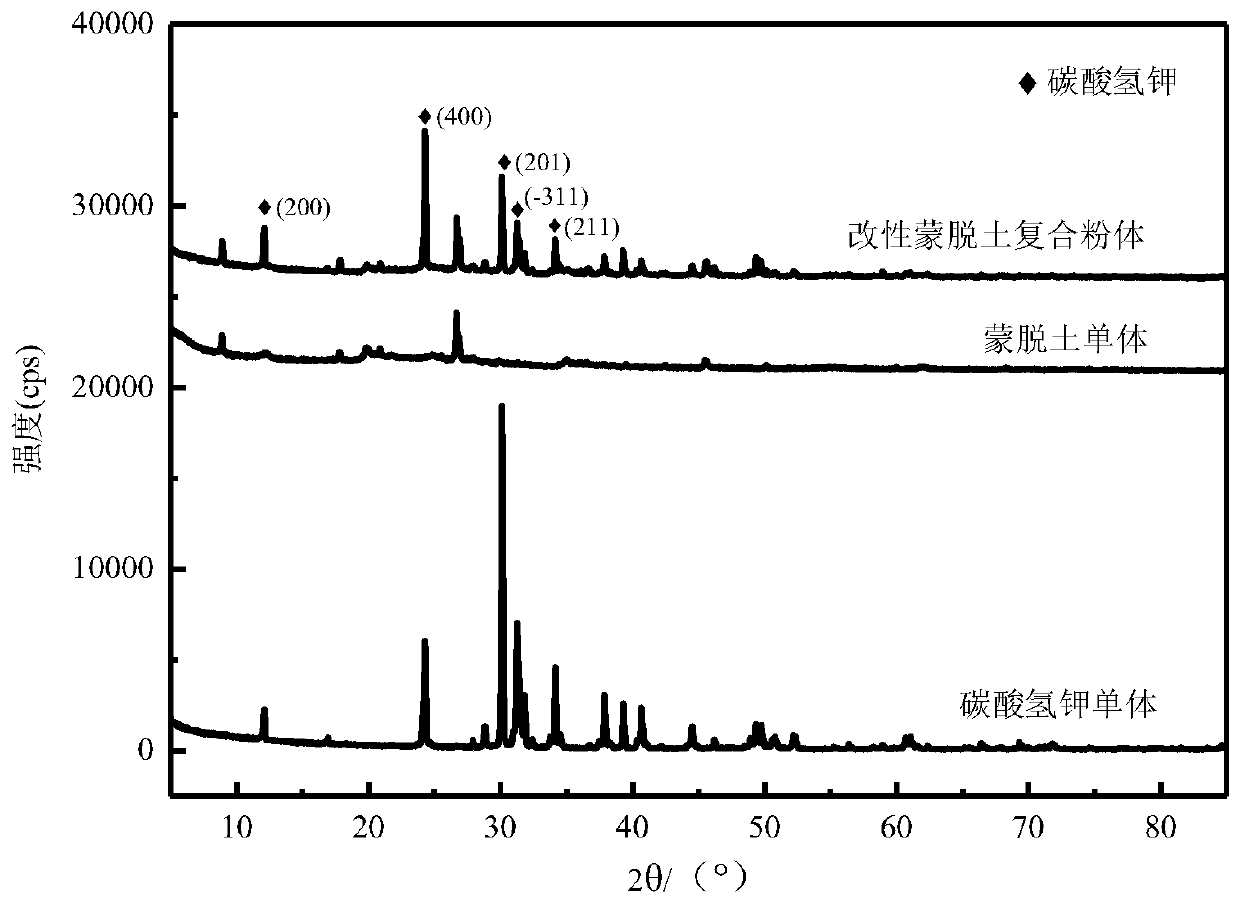

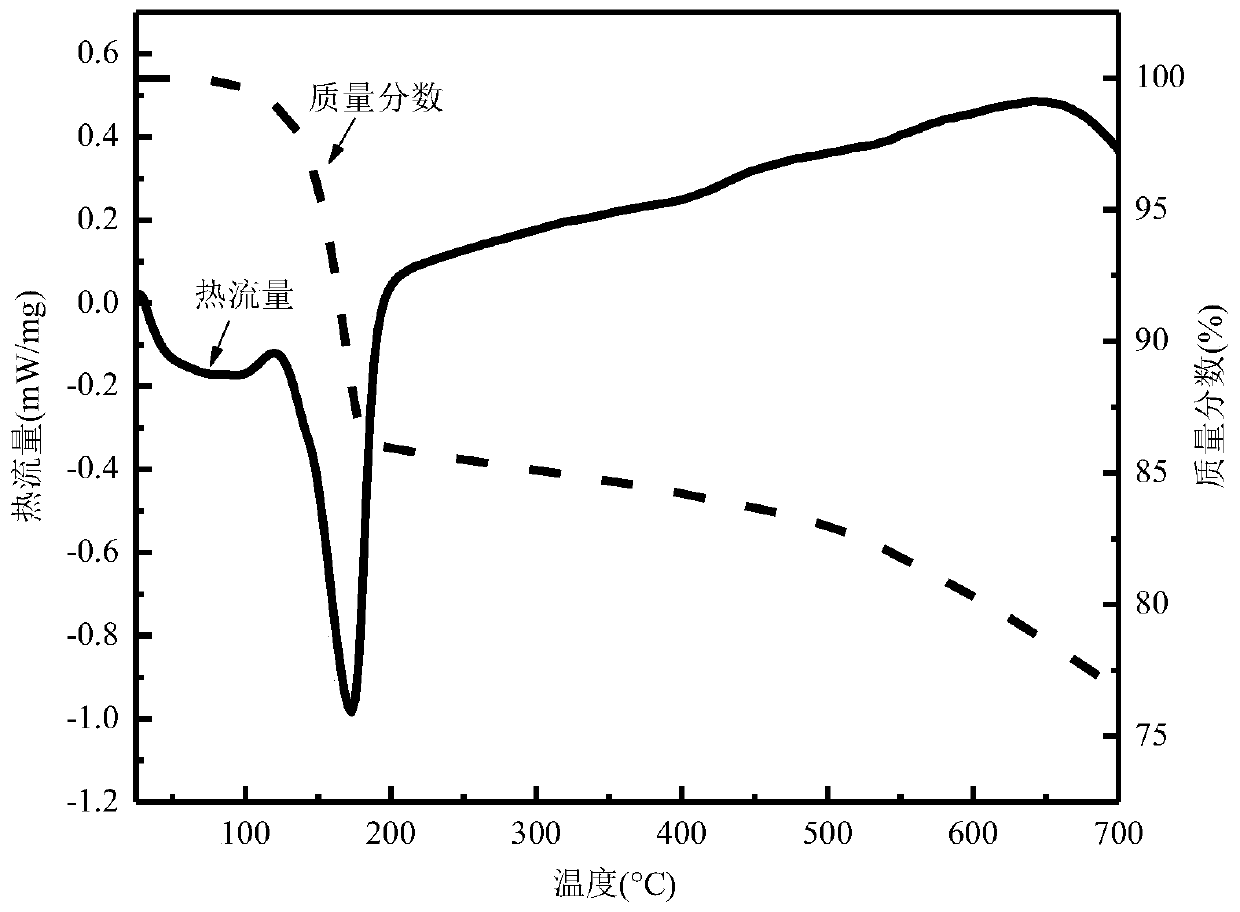

[0057] The raw materials of the superfine montmorillonite-based core-shell structure antiknock agent in this embodiment are: 6 parts of montmorillonite, 3 parts of potassium bicarbonate, and 1 part of hydrophobic fumed silica.

[0058] Its preparation method is as follows:

[0059] Step 1: Ball mill the montmorillonite and potassium bicarbonate for 15 minutes respectively, the ball-to-material ratio is 2.5:1, and the frequency is 40Hz. After ball milling, put it into a drying oven to dry for 8 hours, and control the temperature at 40 degrees Celsius.

[0060] Step 2: Dissolve 39.1g of dried potassium bicarbonate into 100mL of distilled water; under magnetic stirring, disperse 78.2g of dried montmorillonite into 250mL of absolute ethanol, and then slowly pour saturated hydrogencarbonate After the addition of the potassium aqueous solution, continue magnetic stirring for 4 hours, then age the precipitate for 4 hours, filter out the precipitate, and dry at 30 degrees Celsius for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com