A method for preparing cobalt-sulfur thin films on copper surfaces based on reverse displacement

A technology of reverse displacement and copper surface, applied in chemical instruments and methods, physical/chemical process catalysts, liquid chemical plating, etc., can solve problems such as complex processes, and achieve the effect of less operation process, short time consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

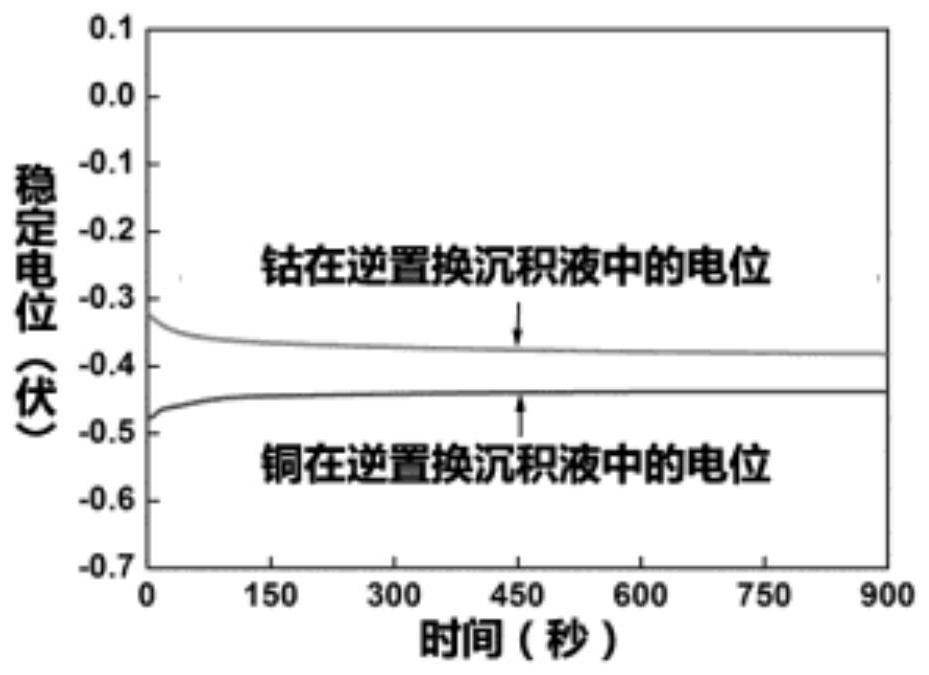

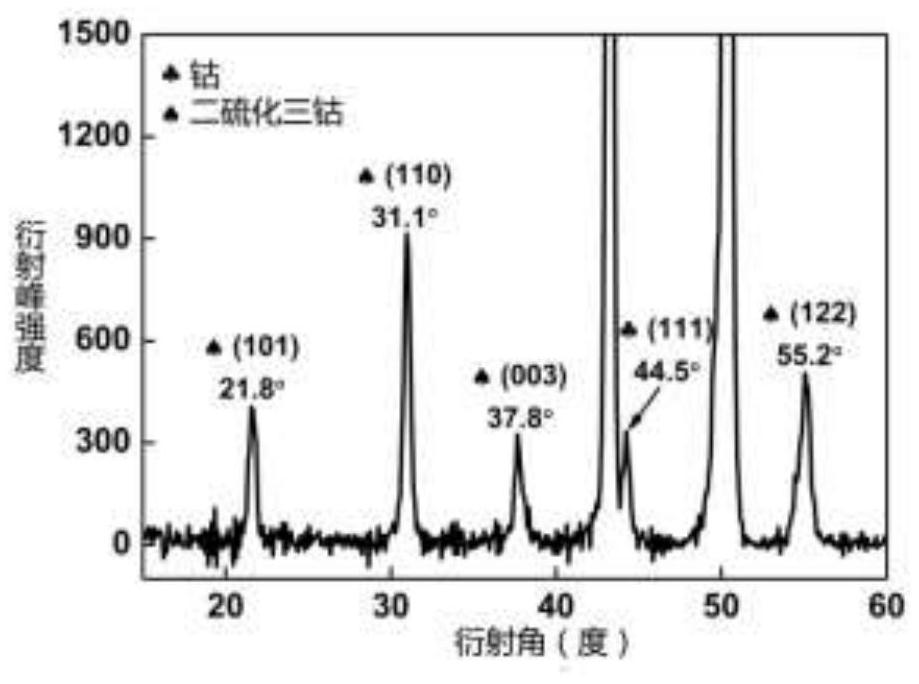

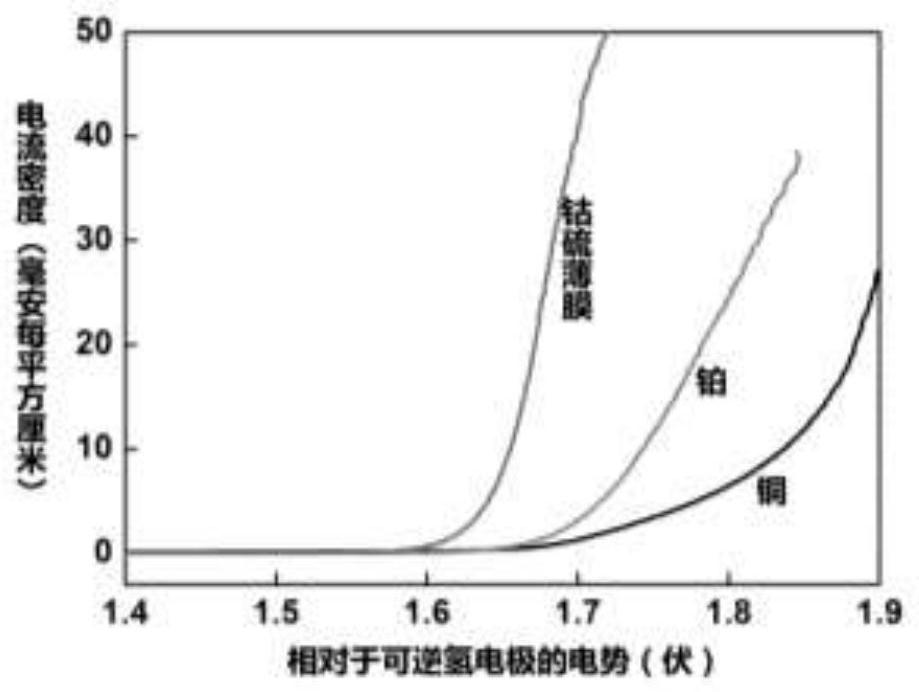

[0023] The present invention designs a method for preparing cobalt-sulfur thin films on copper surfaces based on reverse displacement. The composition of reverse displacement deposition solution and the content of each component are: cobalt chloride 20g / L, sodium thiosulfate 120g / L, dilute Sulfuric acid, etc. to adjust the pH value of the deposition solution to 5. Polish the copper substrate with 400#, 800#, and 1200# sandpaper to remove surface oxides and pollutants; then ultrasonically clean in ethanol solution and dry with nitrogen; then put the polished and cleaned copper sample into reverse displacement deposition The deposition conditions are as follows: reverse displacement deposition solution temperature 20°C, deposition time 10 minutes; after the deposition is completed, take out the copper sheet, wash the residual deposition solution with deionized water, and dry it with nitrogen, then the copper A cobalt-sulfur film is obtained on the surface.

[0024] Because sodi...

Embodiment 2

[0027] The present invention designs a method for preparing cobalt-sulfur thin films on copper surfaces based on reverse displacement. The composition of the reverse displacement deposition solution and the content of each component are: cobalt sulfate 200g / L, sodium thiosulfate 90g / L, dilute sulfuric acid Adjust the pH value of the deposition solution to 7. Polish the copper substrate with 400#, 800#, and 1200# sandpaper to remove surface oxides and pollutants; then ultrasonically clean in ethanol solution and dry with nitrogen; then put the polished and cleaned copper sample into reverse displacement deposition The deposition conditions are as follows: the temperature of the reverse displacement deposition solution is 40°C, and the deposition time is 20 minutes; after the deposition is completed, the copper sheet is taken out, the residual deposition solution is cleaned with deionized water, and dried with nitrogen, which can be deposited on the copper surface A cobalt-sulfu...

Embodiment 3

[0029] The present invention designs a method for preparing cobalt-sulfur thin films on the copper surface based on reverse displacement. The composition of the reverse displacement deposition solution and the content of each component are: cobalt nitrate 10g / L, sodium thiosulfate 320g / L, dilute sulfuric acid Adjust the pH value of the deposition solution to 3. Polish the copper substrate with 400#, 800#, and 1200# sandpaper to remove surface oxides and pollutants; then ultrasonically clean in ethanol solution and dry with nitrogen; then put the polished and cleaned copper sample into reverse displacement deposition Deposition in the liquid, the deposition conditions are: the temperature of the reverse displacement deposition liquid is 80 ° C, and the deposition time is 5 minutes; after the deposition is completed, the copper sheet is taken out, the residual deposition liquid is cleaned with deionized water, and dried with nitrogen, which can be deposited on the copper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com