Nitrogen-phosphorus-doped carbon-coated metal phosphide as well as preparation method and application thereof

A technology of metal phosphide and carbon wrapping, which is applied in the direction of nanotechnology, electrodes, nanotechnology, etc. for materials and surface science, can solve the problems of increasing the cost of catalyst materials, environmental pollution, etc., and achieve easy operation, environmental friendliness and environmental protection The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a metal phosphide catalyst Co wrapped with nitrogen and phosphorus doped carbon 2 P@NPC, which is prepared by the following steps:

[0046] Weigh 0.2 g of biological material DNA and dissolve it in 50 mL of water, heat and stir at 110 °C for 10 min, then quickly put the reacted solution into a cold well at a temperature of -25 °C.

[0047] After maintaining at -25°C for 30min, take it out, return to room temperature and add 20mL of CoCl with a concentration of 20mol / L dropwise 2 The solution was stirred at room temperature for 12h. The solution was then lyophilized to obtain a purple fluffy object after the water was removed. The material was calcined at 800 °C for 2 h under the protection of argon to obtain a nitrogen-phosphorus-doped carbon-wrapped metal phosphide catalyst Co 2 P@NPC.

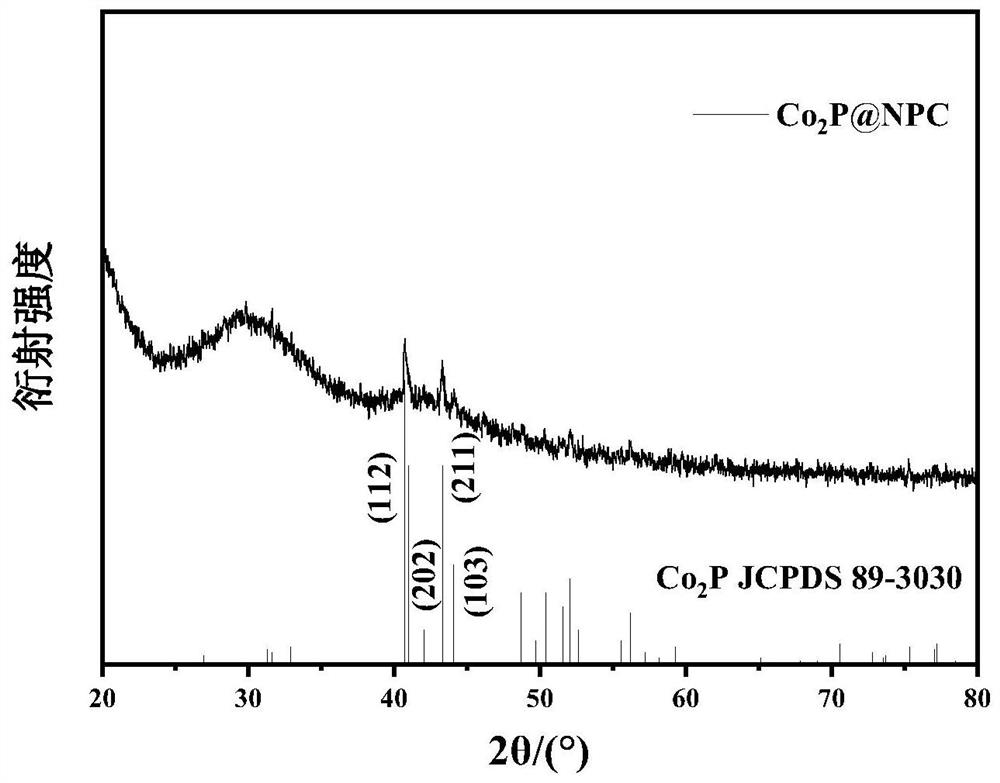

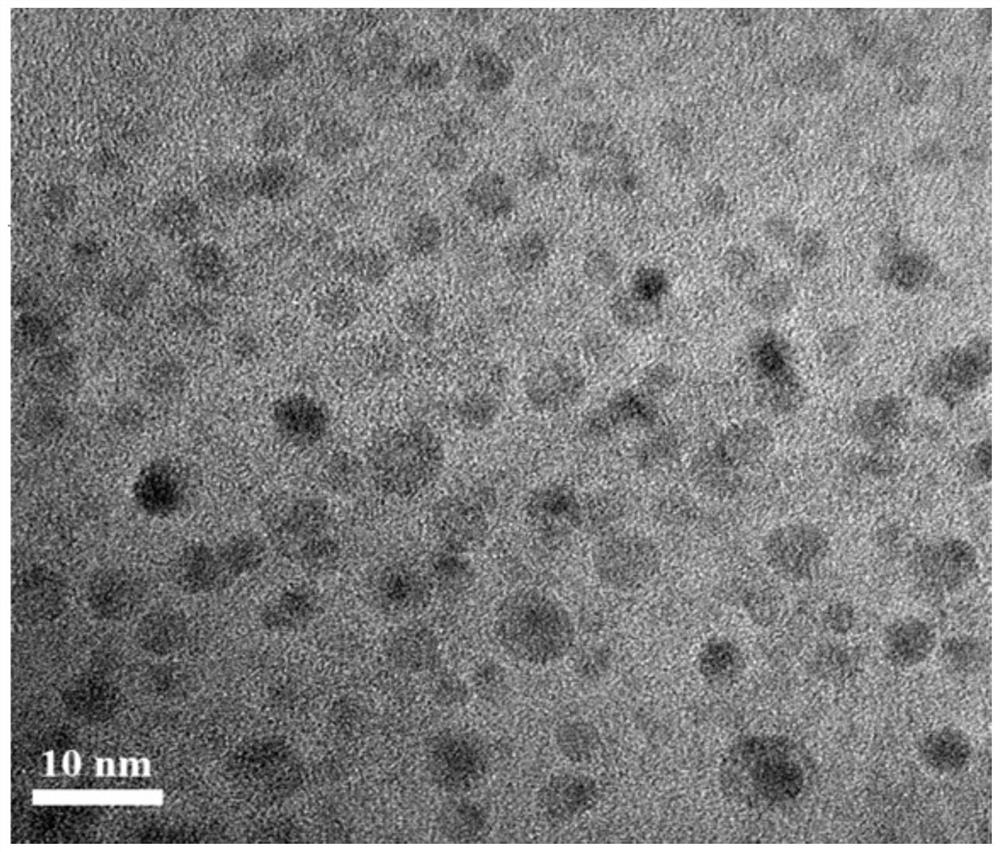

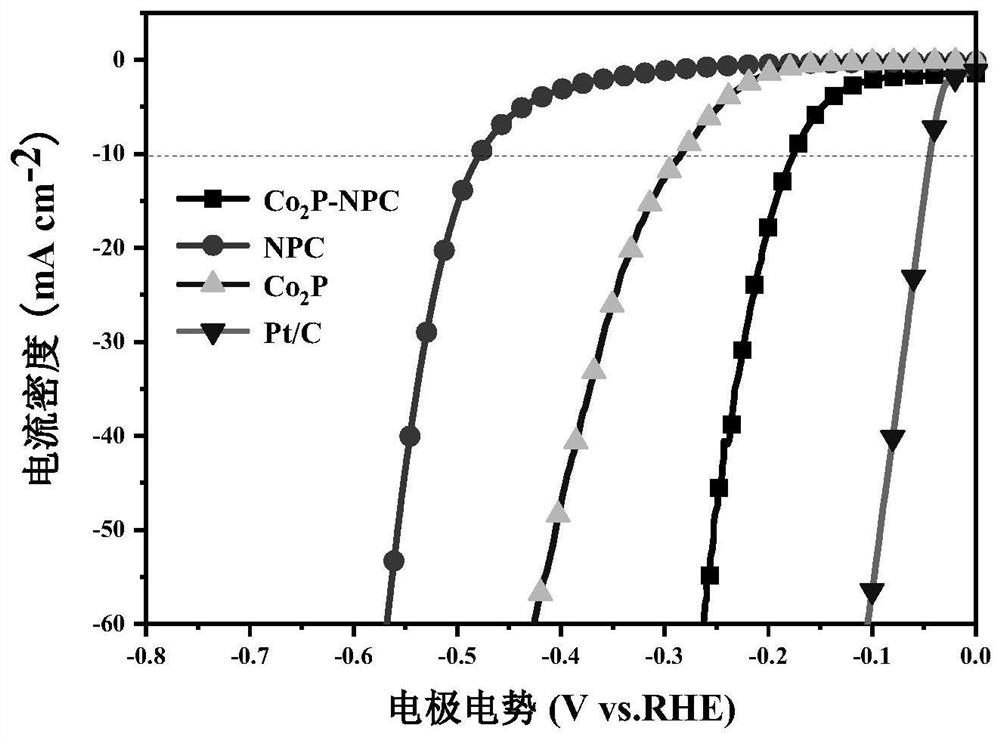

[0048] figure 1 It is the XRD pattern of the nitrogen-phosphorus-doped carbon-wrapped metal phosphide catalyst of Example 1. figure 1 It can be seen that...

Embodiment 2

[0061] This embodiment provides a metal phosphide catalyst Ni that is wrapped with nitrogen and phosphorus doped carbon. 2 P@NPC, which is prepared by the following steps:

[0062] Weigh 0.2 g of biological material DNA and dissolve it in 50 mL of water, heat and stir at 95 °C for 10 min, then quickly put the reacted solution into a cold well at a temperature of -30 °C.

[0063] Take it out after maintaining at -30°C for 30min, return to room temperature and add 20mL of NiCl with a concentration of 20mol / L dropwise 2 The solution was stirred at room temperature for 12h. The solution was then lyophilized to obtain a purple fluffy object after the water was removed. The material was calcined at 700 °C for 2 h under the protection of argon to obtain a nitrogen-phosphorus-doped carbon-wrapped metal phosphide catalyst Ni 2 P@NPC.

[0064] Figure 6 It is the BET diagram of the nitrogen-phosphorus-doped carbon-wrapped metal phosphide catalyst of Example 2. From Figure 6 It c...

Embodiment 3

[0066] This embodiment provides a metal phosphide catalyst Co wrapped with nitrogen and phosphorus doped carbon 2 P@NPC, which is prepared by the following steps:

[0067] Weigh 0.2g of biological material DNA and dissolve it in 50mL of water, heat and stir at 100°C for 10min, then quickly put the reacted solution into a cold well at a temperature of -35°C.

[0068] After maintaining at -35°C for 30 min, it was taken out, returned to room temperature, and 20 mL of cobalt acetate solution with a concentration of 20 mol / L was added dropwise, and stirred at room temperature for 12 h. The solution was then lyophilized to obtain a purple fluffy object after the water was removed. The material was calcined at 750 °C for 2 h under the protection of argon to obtain a nitrogen-phosphorus-doped carbon-wrapped metal phosphide catalyst Co 2 P@NPC.

[0069] Figure 7 It is the SEM image of the metal phosphide catalyst wrapped with nitrogen and phosphorus doped carbon in Example 3. Fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com