Water decomposition catalyst and preparation method and application thereof

A catalyst and water technology, applied in the field of electrochemical catalysis, can solve the problems of low reserves, high cost, limited large-scale application, etc., and achieve the effects of high catalytic activity, high stability, and excellent electrocatalytic water splitting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

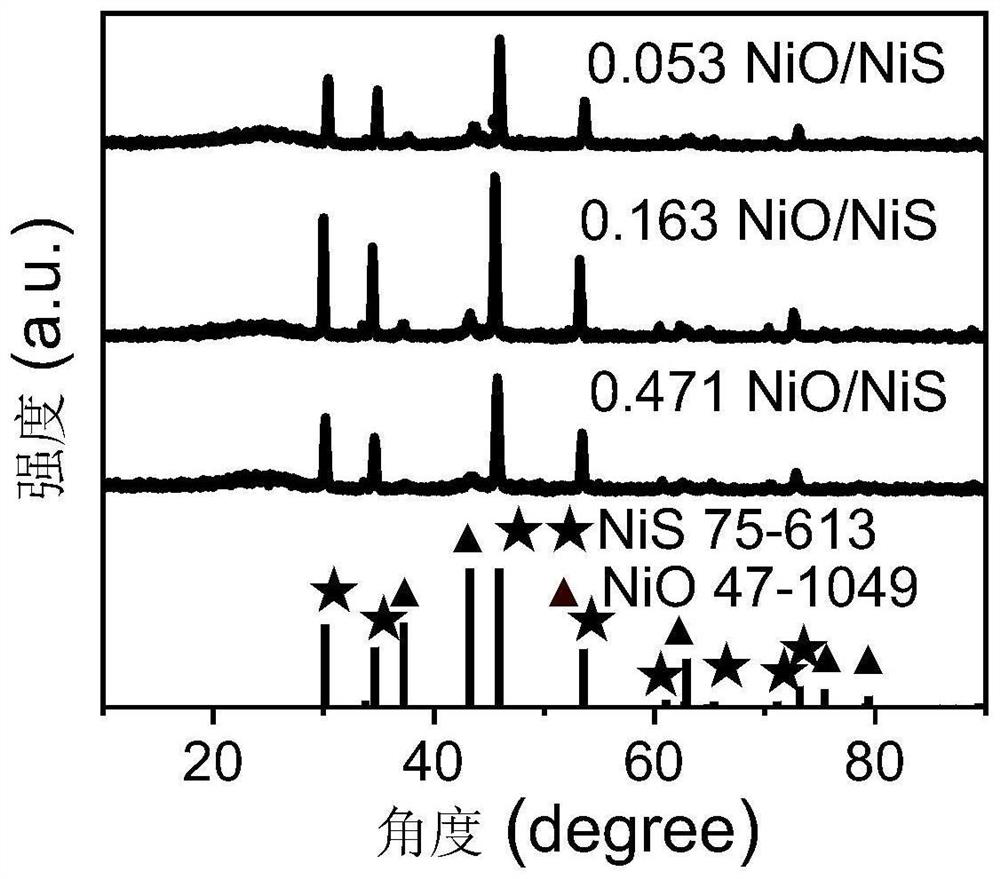

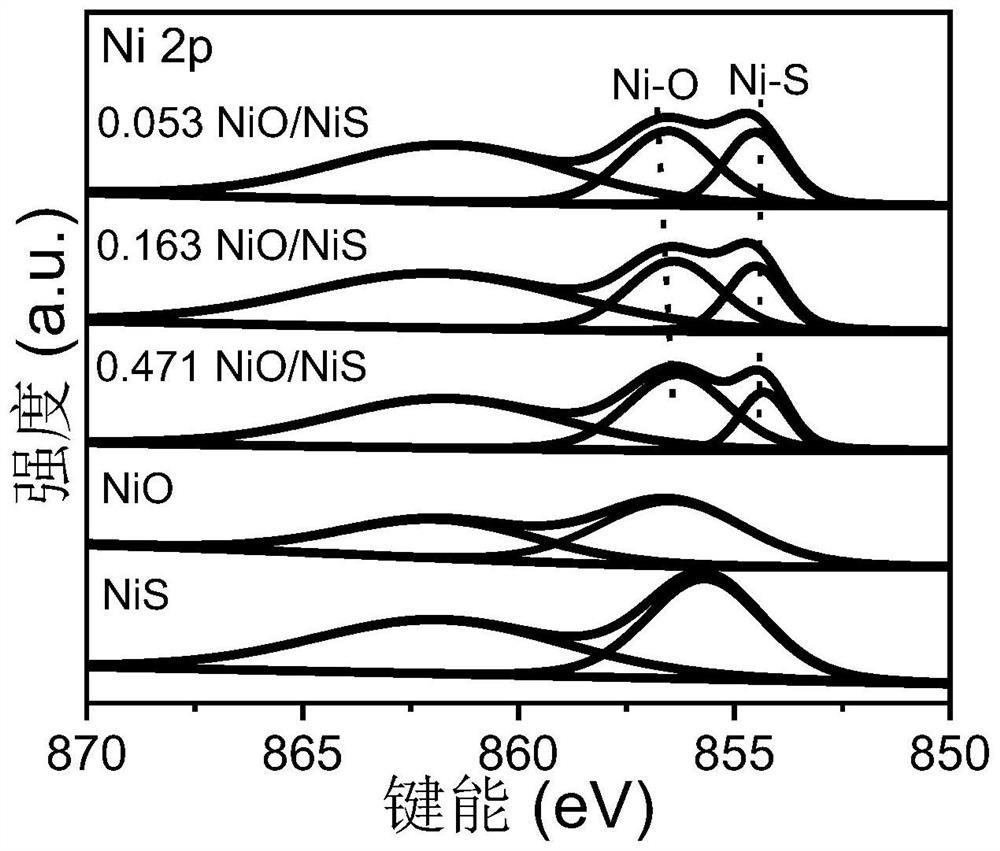

[0063] Example 1 Preparation process of water splitting catalyst 0.053NiO / NiS

[0064] 1) Cut the carbon cloth according to the size of 2cm x 2cm, put the cut carbon cloth into ethanol for ultrasonic 15min, wash it with ethanol for several times after taking it out, place the carbon cloth in a beaker, add concentrated nitric acid until the carbon cloth has passed, Violent reaction produces reddish-brown NO 2 , to NO 2 Wash the carbon cloth with a large amount of ultrapure water, put it into ultrapure water for ultrasound, then put it into ethanol for ultrasound, repeat the cleaning three times, and then store it in ultrapure water;

[0065] 2) Arrange the obtained carbon on the electrode clip as the working electrode, the platinum sheet electrode as the counter electrode, the Ag / AgCl electrode as the reference electrode, and 20ml of 0.1M nickel nitrate solution as the electrode solution, using electrochemical deposition method at -1V , electrodeposited carbon cloth for 20 mi...

Embodiment 2

[0069] Example 2 Preparation process of water splitting catalyst 0.163NiO / NiS

[0070] 1) Cut the carbon cloth according to the size of 2cm x 2cm, put the cut carbon cloth into ethanol for ultrasonic 15min, wash it with ethanol for several times after taking it out, place the carbon cloth in a beaker, add concentrated nitric acid until the carbon cloth has passed, Violent reaction produces reddish-brown NO 2 , to NO 2 Wash the carbon cloth with a large amount of ultrapure water, put it into ultrapure water for ultrasound, then put it into ethanol for ultrasound, repeat the cleaning three times, and then store it in ultrapure water;

[0071] 2) Arrange the obtained carbon on the electrode clip as the working electrode, the platinum sheet electrode as the counter electrode, the Ag / AgCl electrode as the reference electrode, and 20ml of 0.1M nickel nitrate solution as the electrode solution, using electrochemical deposition method at -1V , electrodeposited carbon cloth for 20 mi...

Embodiment 3

[0074] Example 3 Preparation process of water splitting catalyst 0.471NiO / NiS

[0075] 1) Cut the carbon cloth according to the size of 2cm x 2cm, put the cut carbon cloth into ethanol for ultrasonic 15min, wash it with ethanol for several times after taking it out, place the carbon cloth in a beaker, add concentrated nitric acid until the carbon cloth has passed, Violent reaction produces reddish-brown NO 2 , to NO 2 Wash the carbon cloth with a large amount of ultrapure water, put it in ultrapure water for 15 minutes, then put it in ethanol for 15 minutes, repeat the cleaning three times, and then store it in ultrapure water;

[0076] 2) Arrange the obtained carbon on the electrode clip as the working electrode, the platinum sheet electrode as the counter electrode, the Ag / AgCl electrode as the reference electrode, and 20ml of 0.1M nickel nitrate solution as the electrode solution, using electrochemical deposition method at -1V , nickel hydroxide was obtained by electrodep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com