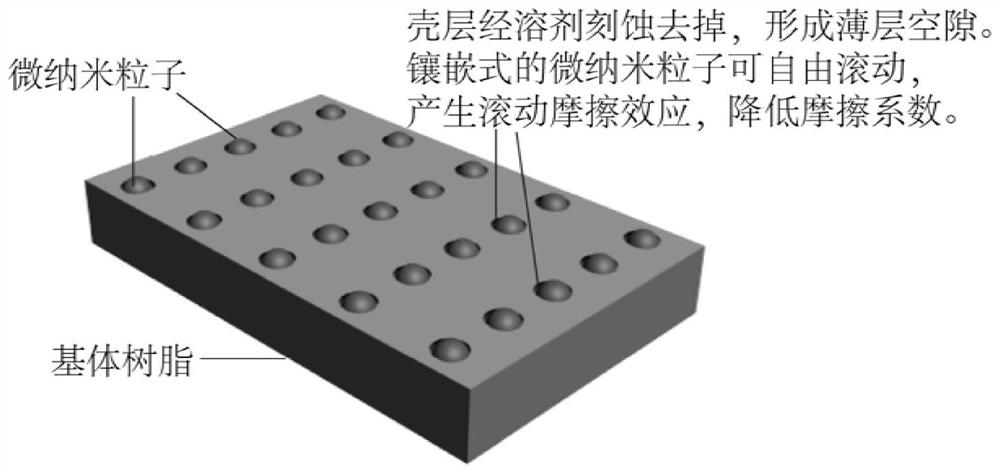

A preparation method of self-lubricating coating material with micro-nano ball effect

A technology of self-lubricating coating and ball effect, which is applied in the field of preparation of self-lubricating coating materials, can solve problems such as the stability of contaminated plating solution, improve self-lubricating ability and service life, unique stress buffering and shock absorption, Increase the effect of the rolling friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of self-lubricating base layer:

[0035] Mix and disperse 80g of matrix resin, 20g of solid lubricant, and 20g of solvent by means of ultrasonic and mechanical stirring to obtain a self-lubricating spray coating. The coating is formed on the surface of the metal substrate by thermal spraying, and the self-lubricating base layer is prepared by hot-pressing and pre-curing.

[0036] 2. Preparation of self-lubricating coating material with nano ball effect:

[0037] (1) Preparation of core-shell structure inorganic@organic micro-nanoparticles

[0038]Disperse 10g of inorganic nanoparticles in 10L of absolute ethanol, add 1g of bifunctional catechol monomer Im-Ca under stirring at room temperature, stir evenly for 30min, add 1g of bifunctional phenylboronic acid monomer Im-BA, and continue to The reaction was stirred for 24 hours to obtain nanoparticles with core-shell structure.

[0039] (2) Preparation of mosaic self-lubricating surface layer

[0040] Dis...

Embodiment 2

[0042] 1. Preparation of self-lubricating base layer:

[0043] 65g of matrix resin, 10g of solid lubricant and 5g of solvent were mixed and dispersed uniformly by means of ultrasonic and mechanical stirring to obtain a self-lubricating spray coating. The coating was formed on the surface of the metal substrate by thermal spraying, and the self-lubricating base layer was prepared by hot pressing and pre-curing.

[0044] 2. Preparation of self-lubricating coating material with nano ball effect:

[0045] (1) Preparation of core-shell structure inorganic@organic micro-nanoparticles

[0046] Disperse 5 g of inorganic nanoparticles in 10 L of absolute ethanol, add 0.1 g of bifunctional catechol monomer Im-Ca under stirring at room temperature, and add 0.1 g of bifunctional phenylboronic acid monomer Im-BA after uniform stirring for 20 minutes. The stirring reaction at room temperature was continued for 24 hours to obtain nanoparticles with core-shell structure.

[0047] (2) Prepar...

Embodiment 3

[0050] 1. Preparation of self-lubricating base layer:

[0051] 50g matrix resin, 5g solid lubricant and 5g solvent were mixed and dispersed uniformly by means of ultrasonic and mechanical stirring to obtain a self-lubricating spray coating. The coating was formed on the surface of the metal substrate by thermal spraying, and the self-lubricating base layer was prepared by hot-pressing pre-curing.

[0052] 2. Preparation of self-lubricating coating material with nano ball effect:

[0053] (1) Preparation of core-shell structure inorganic@organic micro-nanoparticles

[0054] Disperse 1g of inorganic nanoparticles in 2L of absolute ethanol, add 0.5g of bifunctional catechol monomer Im-Ca under stirring at room temperature, and add 0.5g of bifunctional phenylboronic acid monomer Im-BA after uniform stirring for 10 minutes. The stirring reaction at room temperature was continued for 12 hours to obtain nanoparticles with core-shell structure.

[0055] (2) Preparation of mosaic sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com