Nanometer ditungsten carbide particles, and preparation method and applications thereof

A technology of ditungsten carbide and nano-particles, which is applied in chemical instruments and methods, carbides, nanotechnology, etc., can solve the problems of cumbersome preparation methods of ditungsten carbide, uncontrollable particle sintering, and low material surface area, and achieve uniform size, The effect of simple operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of nanometer tungsten carbide particles of the present invention comprises the following steps:

[0030] S1. Grinding tungsten trioxide powder and urea in a mortar with a mass ratio of 1:(1~3) and uniformly mixing to obtain a mixture;

[0031] Among them, what are the requirements for grinding treatment;

[0032] S2. Put the mixture in a crucible, heat up to 600-800°C at a rate of 1-8°C / min in a low-temperature tube furnace, then keep it warm for 1-4h, and cool naturally to room temperature to obtain W 2 C nanoparticles.

[0033] The low temperature tube furnace is filled with N 2 atmosphere.

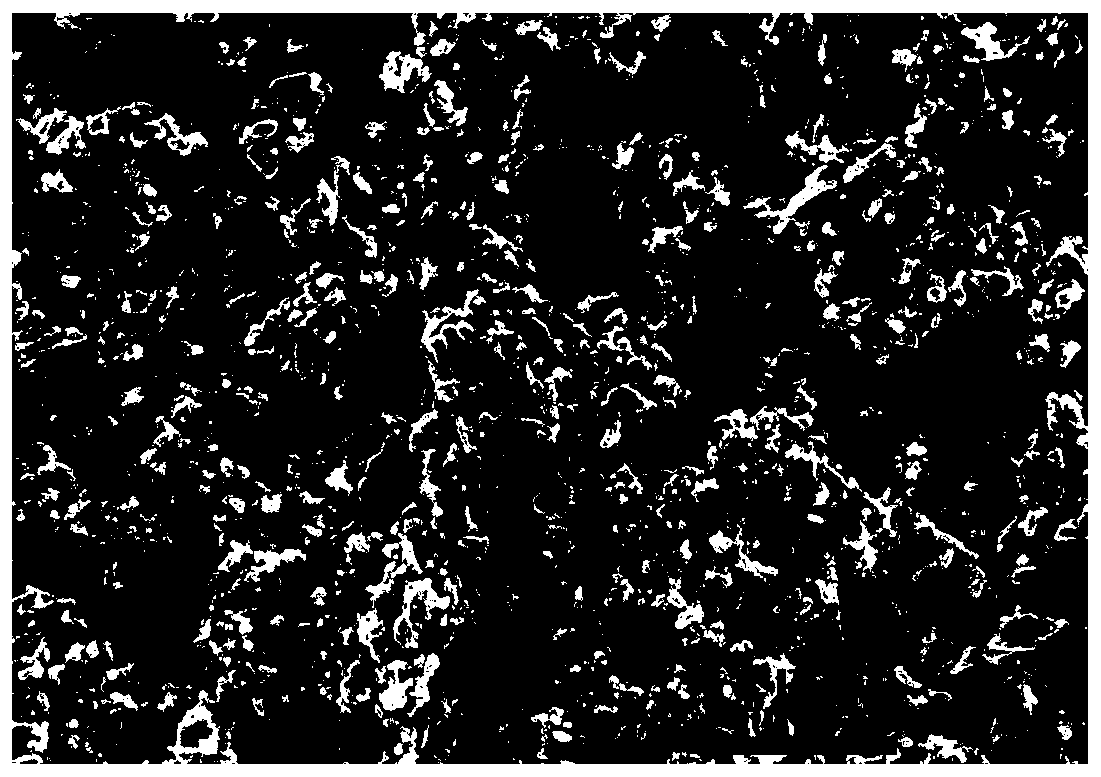

[0034] Prepared W 2 The C nanocrystals have a particle or sheet structure, and the crystals have a particle size of 30-300 nm.

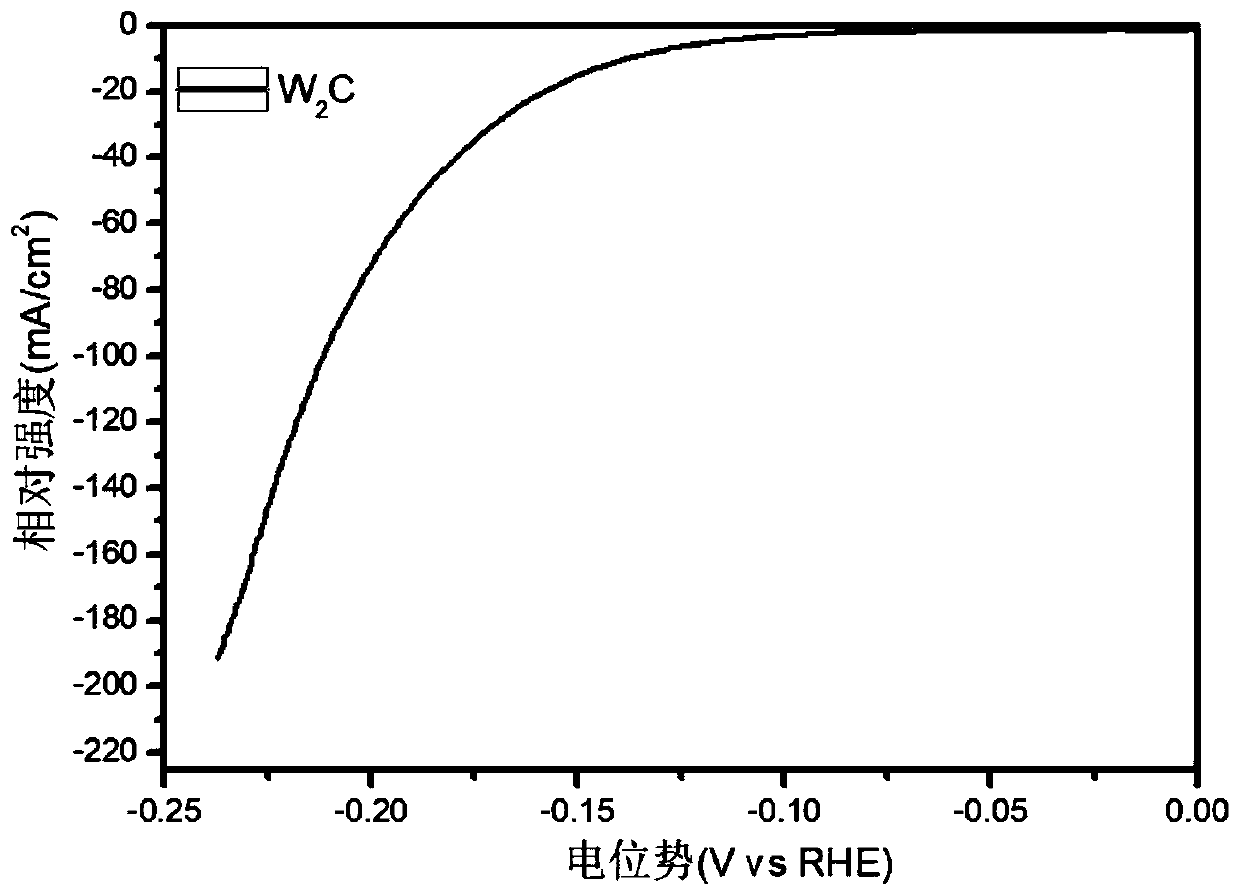

[0035] In the electrochemical test, in order to detect the electrochemical catalytic performance of the nano-tungsten carbide prepared by the present invention, it is used for electrochemical evaluation. In order to detect the...

Embodiment 1

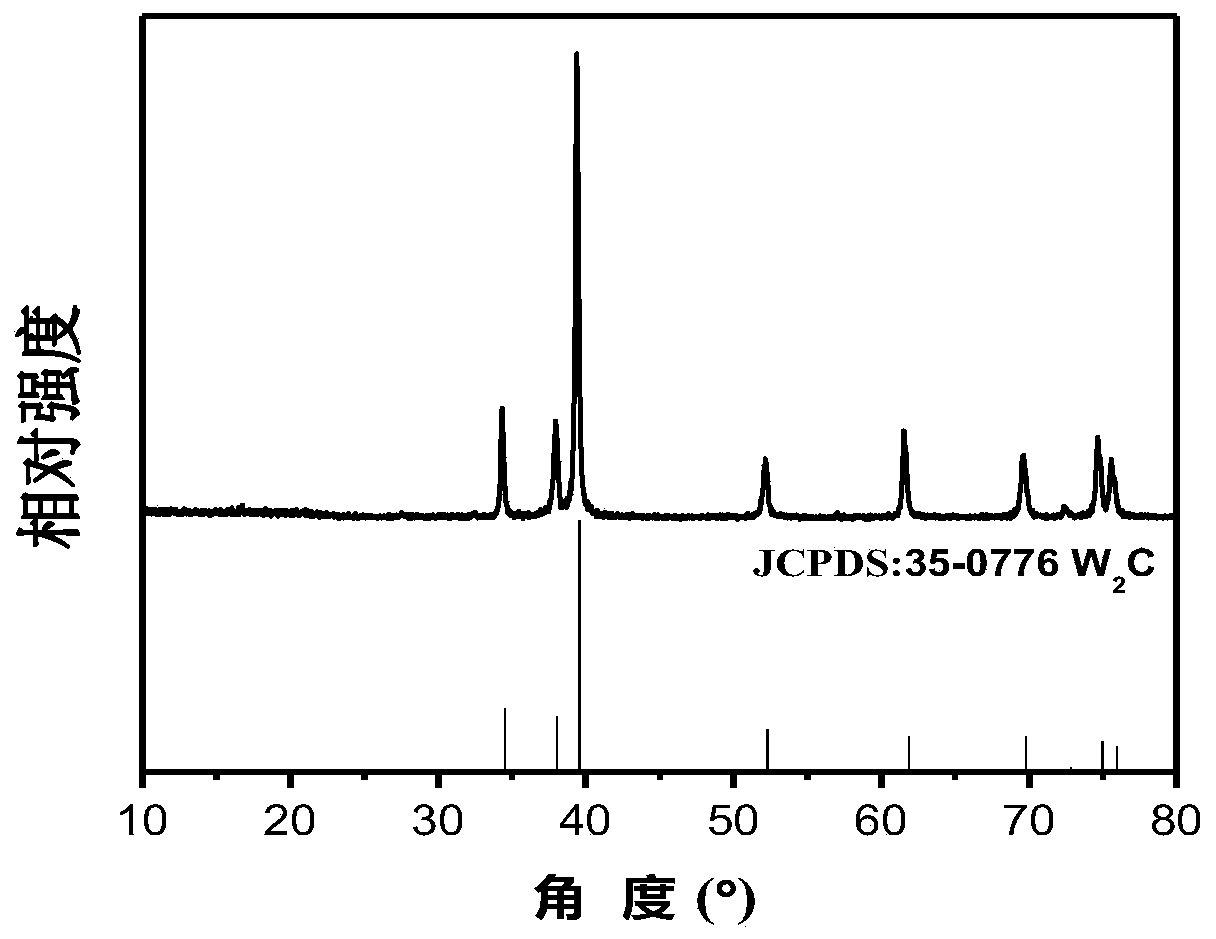

[0042] Grind urea and tungsten trioxide powder in a mortar with a mass ratio of 2:1 and mix them evenly, and transfer the mixture to a crucible; after placing the mixture in the crucible, use flowing N 2 For protection, the temperature was raised to 700°C at 1°C / min, kept for 2 hours, and then naturally cooled to room temperature to obtain a 30nm W 2 C nanoparticles. The W 2 C nanoparticles seefigure 1 Shown; and has good crystallinity, the d value and relative intensity of its diffraction peak and W 2 The d value listed in the PDF standard card (35-0776) of C is consistent with the relative strength, such as figure 1 and figure 2 shown.

Embodiment 2

[0044] Grind urea and tungsten trioxide powder in a mortar with a mass ratio of 1:1 and mix them evenly, then transfer the mixture to a crucible; after placing the mixture in the crucible, use flowing N 2 For protection, the temperature was raised to 600 °C at 2 °C / min, after 4 hours of heat preservation, and then naturally cooled to room temperature, the d value and relative intensity of the diffraction peak were the same as those of W 2 The d value listed in the PDF standard card (35~0776) of C is consistent with the relative intensity, which is W at 80nm 2 C nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com