Production method of countersunk nozzle rod forming paper

A production method and technology for forming paper, which is applied in the direction of paper, papermaking, packaging paper, etc., can solve the problems of increased longitudinal friction of fibers, many layers of fiber stacking, and affecting product appearance, etc., so as to reduce longitudinal tensile strength and reduce The effect of wearing and maintaining the intact appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

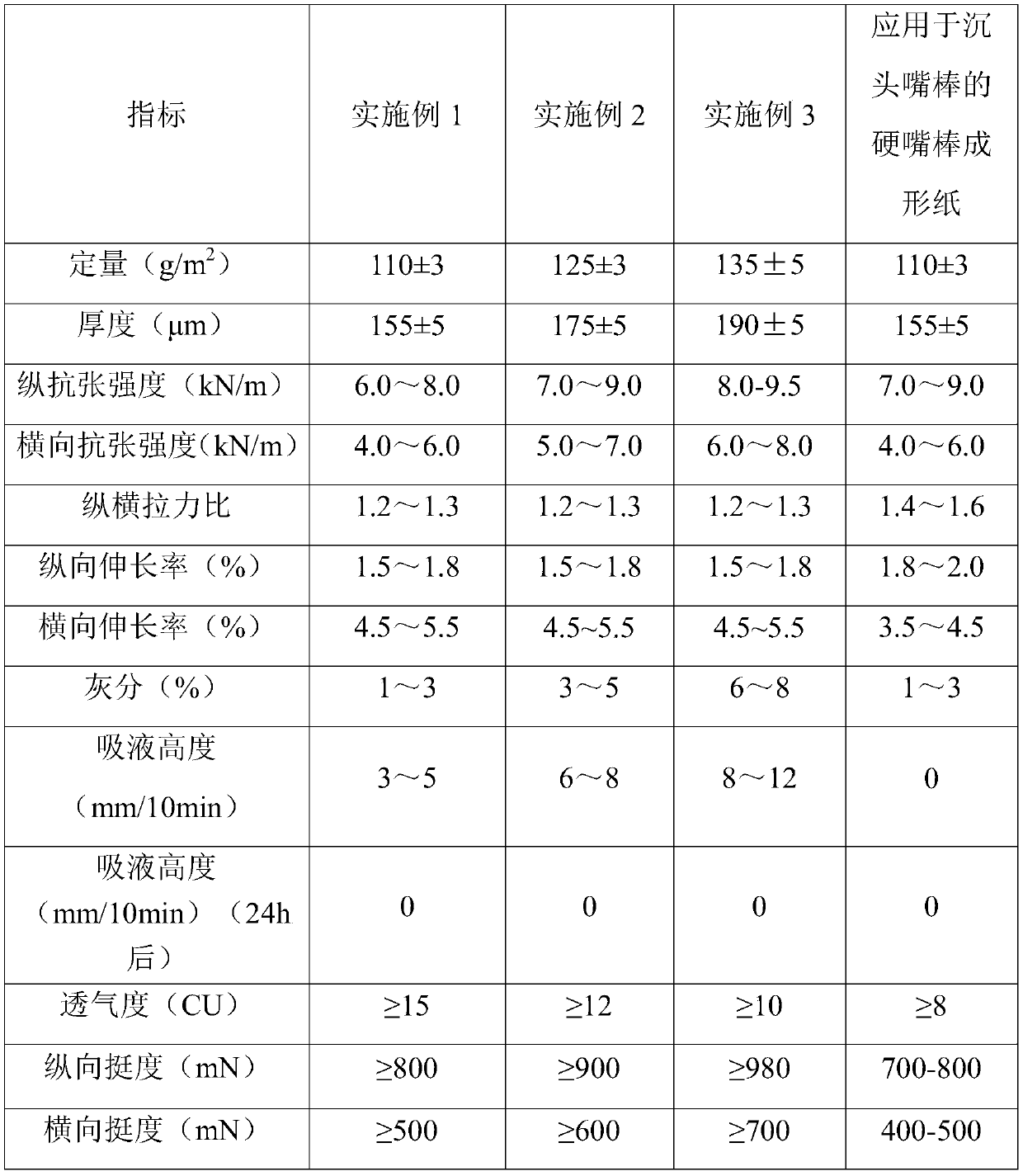

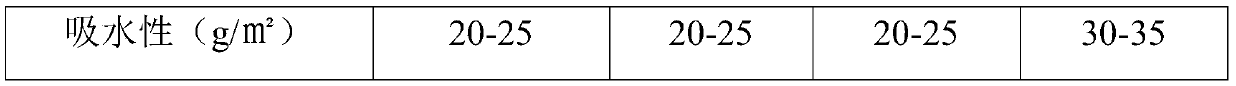

Examples

Embodiment 1

[0029] This embodiment provides a method for producing countersunk nozzle rod forming paper, comprising the following steps:

[0030] (1) Raw material selection: use softwood pulp with fiber length ≥ 2.5mm, fiber thickness ≥ 0.14mg / m, and fiber width 28-35μm; and fiber length ≥ 0.7mm, fiber thickness ≥ 0.08mg / m, Hardwood pulp with a fiber width of 20-35 μm.

[0031] (2) The coniferous pulp and broadleaf pulp are beaten separately; among them, the coniferous pulp is beaten by three disc refiners, the first is a cutting disc refiner, which mainly cuts fibers, the second and the third are broom Disc grinding mainly plays the role of beating degree. This beating method can control the fiber length. While ensuring the beating degree of the fiber, it can control the fiber length and the brooming rate, so that the needle fiber can not be too long when the beating degree is reached, and at the same time it can be exposed. There are enough hydroxyl groups, so that the paper can ensure...

Embodiment 2

[0037] This embodiment provides a method for producing countersunk nozzle rod forming paper, comprising the following steps:

[0038] (1) Raw material selection: use softwood pulp with fiber length ≥ 2.5mm, fiber thickness ≥ 0.14mg / m, and fiber width 28-35μm; and fiber length ≥ 0.7mm, fiber thickness ≥ 0.08mg / m, Hardwood pulp with a fiber width of 20-35 μm.

[0039](2) The coniferous pulp and broadleaf pulp are beaten separately; among them, the coniferous pulp is beaten by three disc refiners, the first is a cutting disc refiner, which mainly cuts fibers, the second and the third are broom Disc grinding mainly plays the role of beating degree. This beating method can control the fiber length. While ensuring the beating degree of the fiber, it can control the fiber length and the brooming rate, so that the needle fiber can not be too long when the beating degree is reached, and at the same time it can be exposed. There are enough hydroxyl groups, so that the paper can ensure ...

Embodiment 3

[0045] This embodiment provides a method for producing countersunk nozzle rod forming paper, comprising the following steps:

[0046] (1) Raw material selection: use softwood pulp with fiber length ≥ 2.5mm, fiber thickness ≥ 0.14mg / m, and fiber width 28-35μm; and fiber length ≥ 0.7mm, fiber thickness ≥ 0.08mg / m, Hardwood pulp with a fiber width of 20-35 μm.

[0047] (2) The coniferous pulp and broadleaf pulp are beaten separately; among them, the coniferous pulp is beaten by three disc refiners, the first is a cutting disc refiner, which mainly cuts fibers, the second and the third are broom Disc grinding mainly plays the role of beating degree. This beating method can control the fiber length. While ensuring the beating degree of the fiber, it can control the fiber length and the brooming rate, so that the needle fiber can not be too long when the beating degree is reached, and at the same time it can be exposed. There are enough hydroxyl groups, so that the paper can ensure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com