Yolk-eggshell structure nanocage catalyst as well as preparation method and application thereof

A catalyst and nano-cage technology, applied in the field of egg yolk-egg-shell structure nano-cage catalyst and its preparation, can solve the problems of ineffective glucose oxidation, many raw materials, and high catalyst cost, shorten the mass transmission distance, increase the collision frequency, The effect of a well-reacted environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

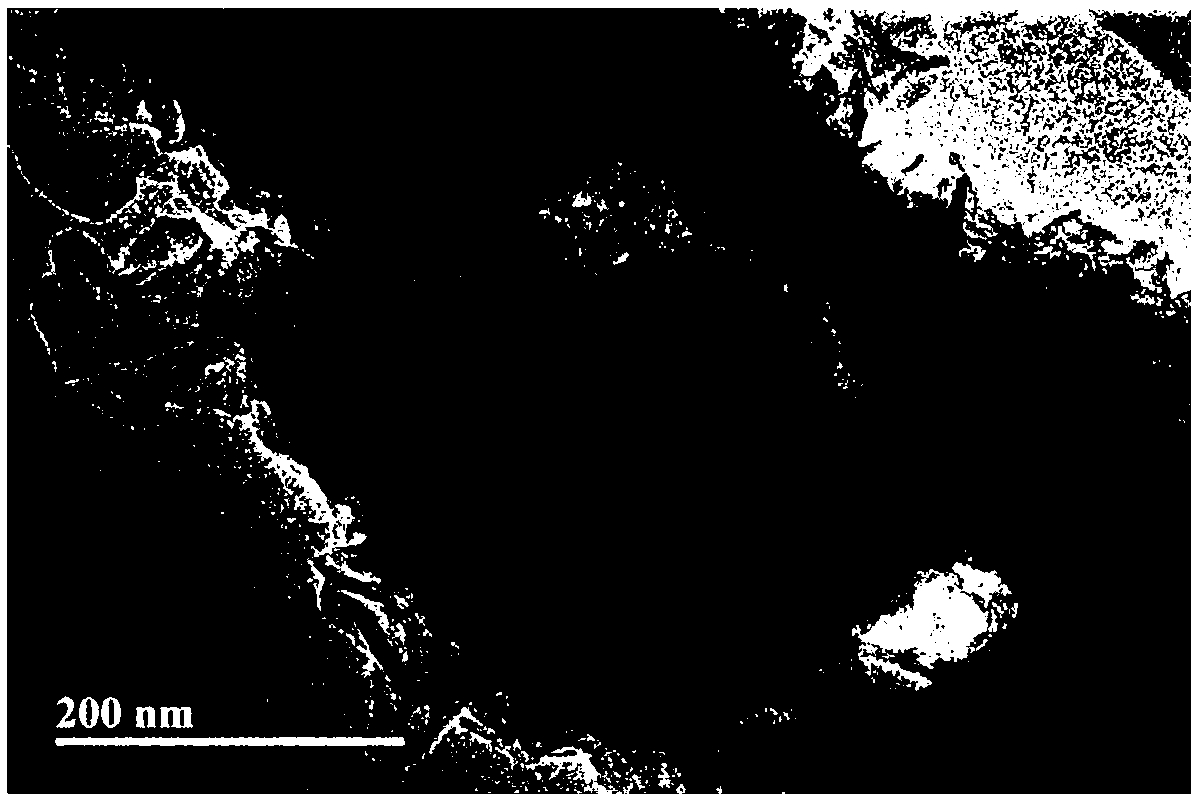

[0064] This embodiment provides a nanocage catalyst with egg yolk-eggshell structure and a preparation method thereof. The catalyst includes two parts, an inner core and a shell, the inner core is cuprous oxide, and the outer shell is cuprous oxide and cobalt hydroxide The composite, wherein the cuprous oxide in the shell accounts for 5wt% of the total mass of the shell, and the cuprous oxide in the catalyst accounts for 35wt% of the total mass of the catalyst.

[0065] The catalyst has an octahedral structure, the particle diameter is 420nm, the thickness of the shell layer is 25nm, and the particle diameter of the inner core is 190nm.

[0066] The preparation method of described catalyst comprises the following steps:

[0067] (1) Disperse 20mg of octahedral cuprous oxide with a particle size of 400nm in a mixed solution of 20mL of water and 20mL of ethanol to form a dispersion, add 2g of PVP and 10mg of cobalt chloride successively, disperse evenly with ultrasonic treatment...

Embodiment 2

[0072] This embodiment provides a nanocage catalyst with egg yolk-eggshell structure and a preparation method thereof. The catalyst includes two parts, an inner core and a shell, the inner core is cuprous oxide, and the outer shell is cuprous oxide and nickel hydroxide The composite, wherein the cuprous oxide in the shell accounts for 3wt% of the total mass of the shell, and the cuprous oxide in the catalyst accounts for 40wt% of the total mass of the catalyst.

[0073] The catalyst has an octahedral structure, the particle diameter is 110nm, the thickness of the shell layer is 20nm, and the particle diameter of the inner core is 40nm.

[0074] The preparation method of described catalyst comprises the following steps:

[0075] (1) Disperse 10mg of octahedral cuprous oxide with a particle size of 100nm in a mixed solution of 25mL of water and 15mL of ethanol to form a dispersion liquid, add 0.5g of PVP and 20mg of nickel nitrate successively, ultrasonically treat for 30min to ...

Embodiment 3

[0080] This embodiment provides a nanocage catalyst with egg yolk-eggshell structure and a preparation method thereof. The catalyst includes two parts, an inner core and a shell, the inner core is cuprous oxide, and the outer shell is cuprous oxide, hydroxide A composite of iron and zinc hydroxide, wherein the cuprous oxide in the shell accounts for 10wt% of the total mass of the shell, and the cuprous oxide in the catalyst accounts for 50wt% of the total mass of the catalyst.

[0081] The catalyst has an octahedral structure, the particle diameter is 1050nm, the thickness of the shell layer is 50nm, and the particle diameter of the inner core is 560nm.

[0082] The preparation method of described catalyst comprises the following steps:

[0083] (1) Disperse 50 mg of octahedral cuprous oxide with a particle size of 1000 nm in a mixed solution of 20 mL of water and 30 mL of ethanol to form a dispersion, first add 7.5 g of sodium citrate, then add 20 mg of ferrous sulfate and 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com