Flotation apparatus and flotation process

A flotation machine and flotation technology are applied in the field of flotation machines, which can solve the problems of uneconomical flotation process and achieve high-yield effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

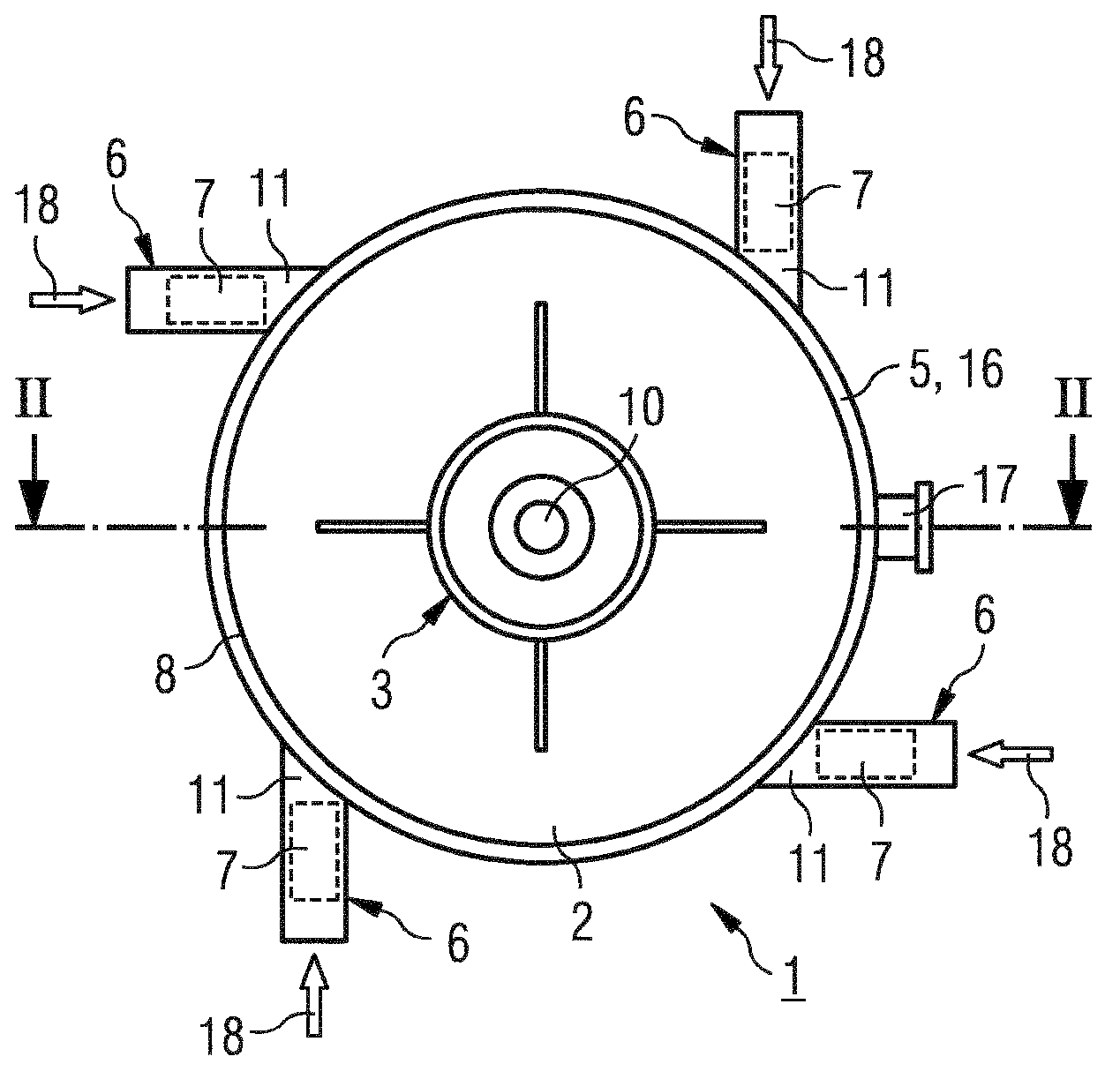

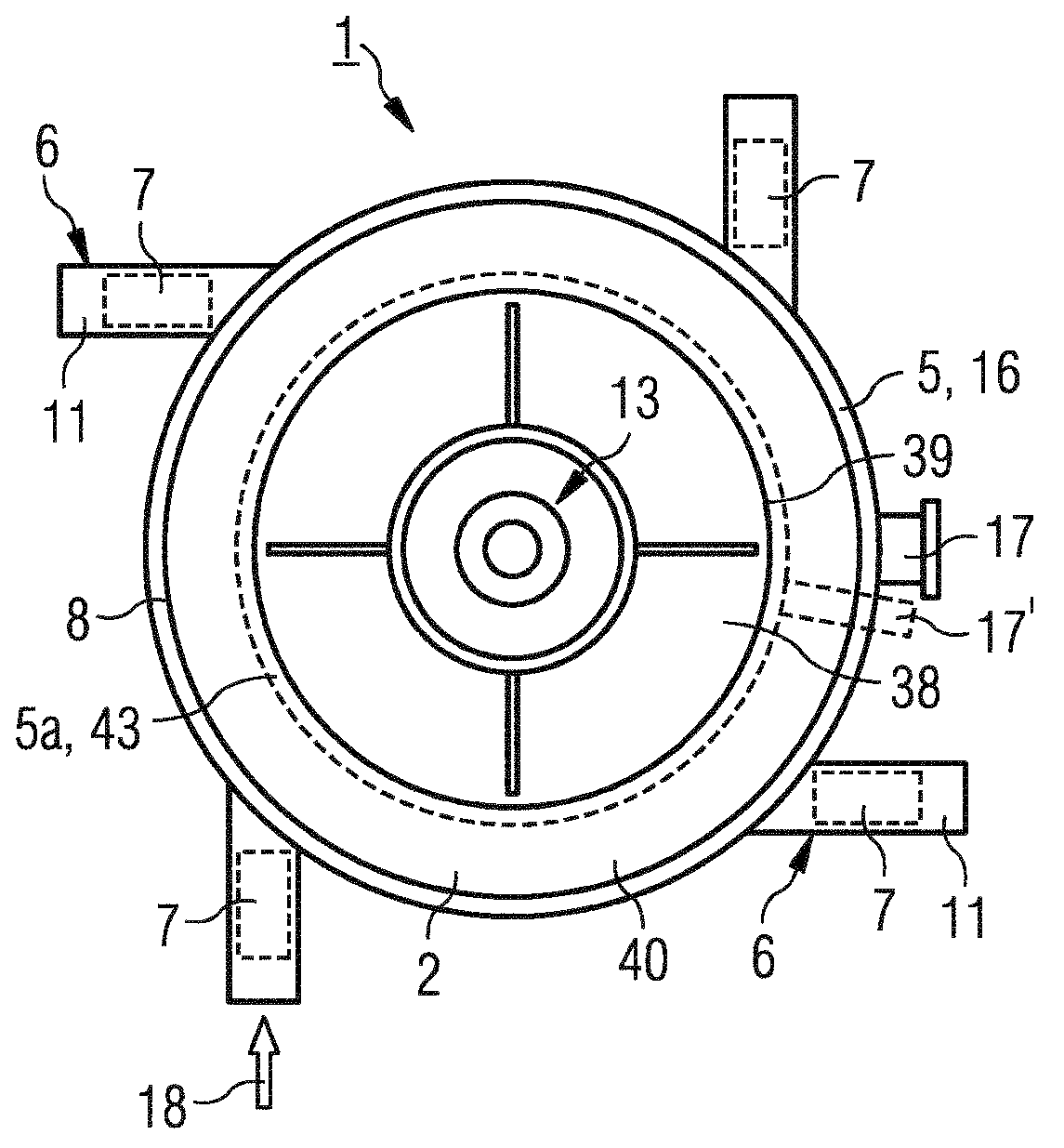

[0017] in accordance with Figure 1-6 The flotation machine 1 shown in the schematic diagram comprises a flotation chamber 2, a froth collecting device 5 and four charging pipes 6 arranged at intervals from each other in the circumferential direction on the flotation chamber 2, and these charging pipes respectively include injectors 7 form of the first mixing device M1, or in which the injector is integrated. Arranged in the flotation chamber 2 is a further second mixing device M2 comprising a stirrer 3 and an aeration device 4 associated with the stirrer 3 . The flotation chamber 2 is delimited by side walls 8 and a bottom 9 having an annular cross-sectional shape. An electric stirrer 3 , designed for example as a stator-rotor system, is arranged on the bottom 9 of the flotation chamber 2 , or in the region below it. The stirrer is connected via a hollow shaft 10 to a drive unit 13 which includes, for example, an electric motor 14 and a transmission 15 connecting the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com