Stainless steel wire cut shot rounding machine and rounding method

A technology of stainless steel wire and stainless steel, which is applied in the field of stainless steel wire cutting shot rounding machine and rounding, can solve the problems of low production efficiency, large equipment loss, long rounding time, etc., and achieve high rounding efficiency, small collision loss, The effect of increasing the frequency of mutual collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

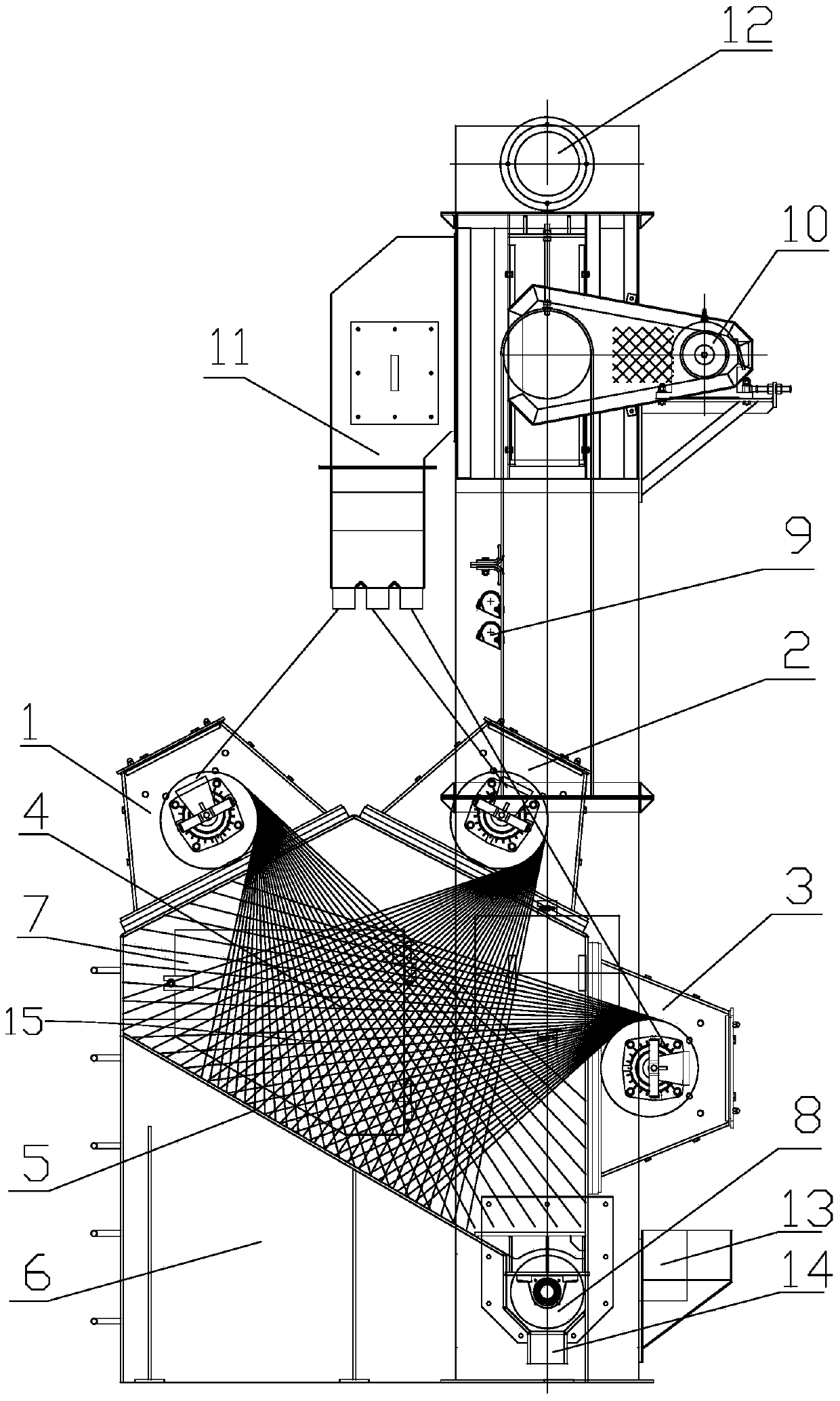

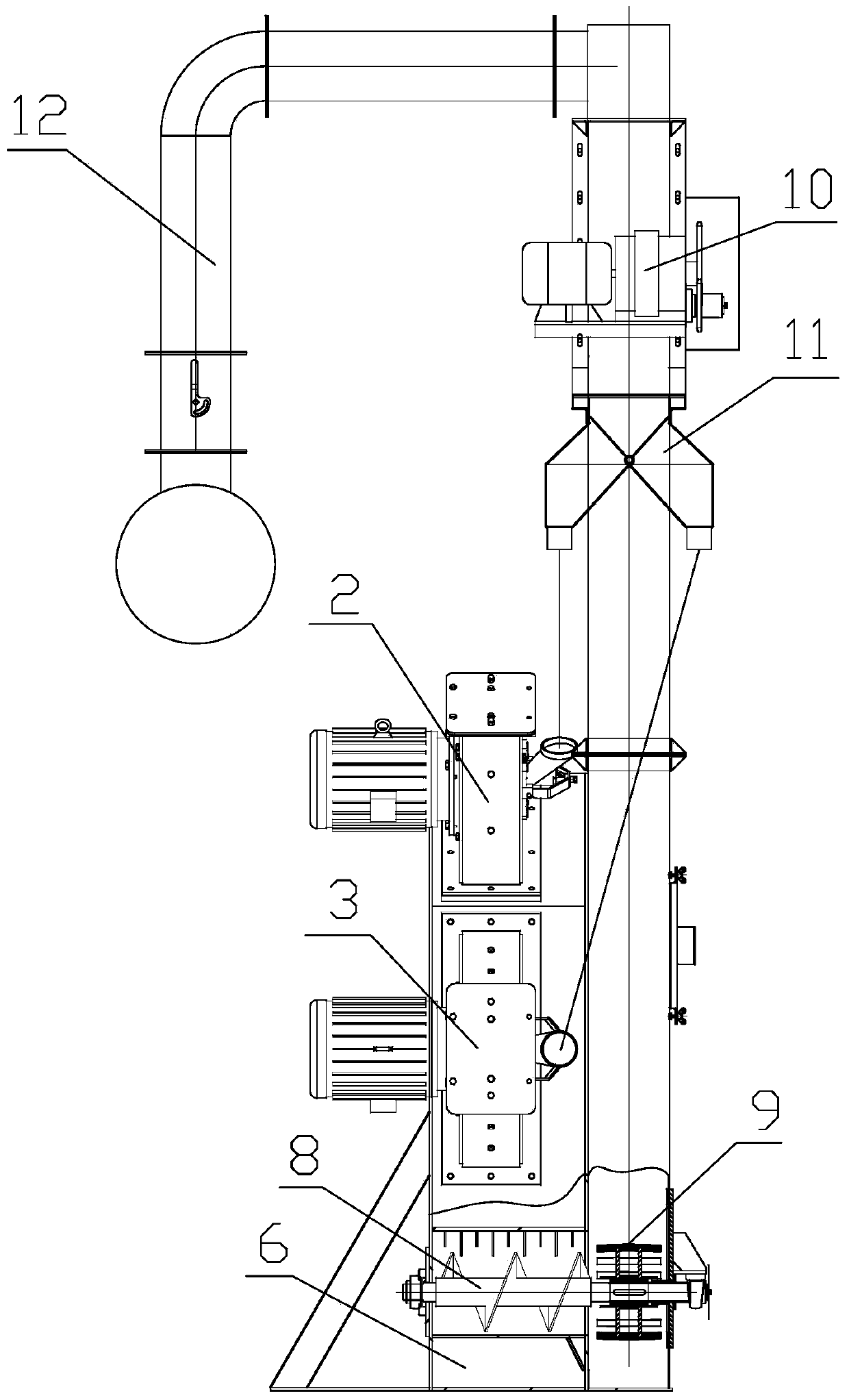

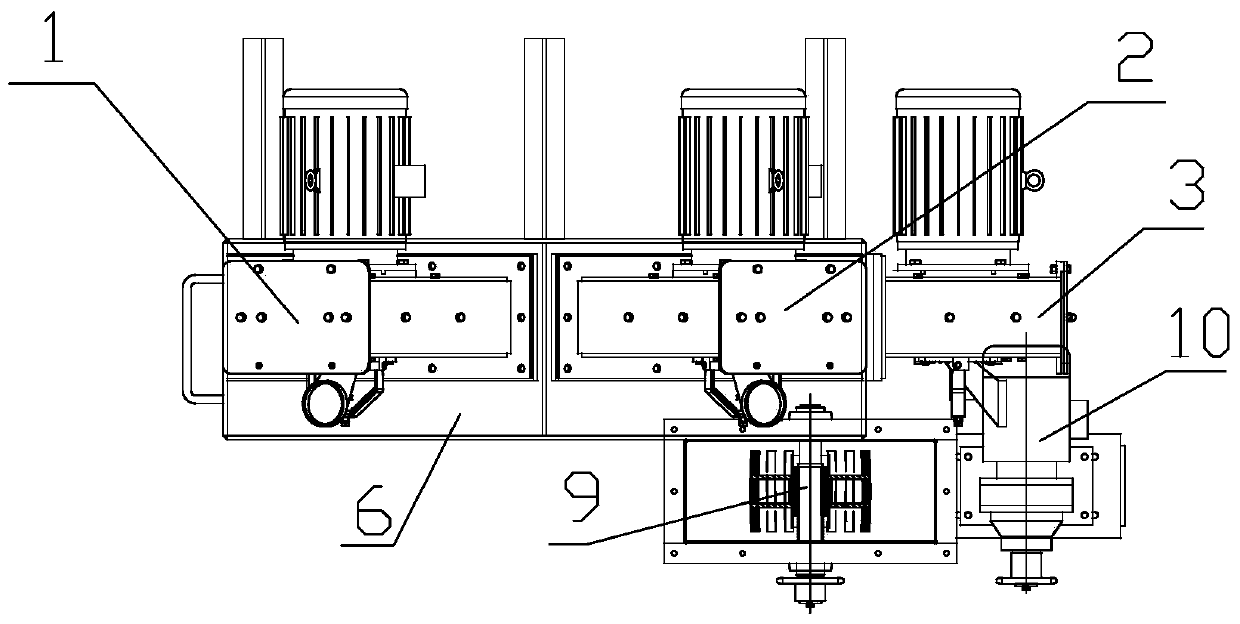

[0019] Such as Figure 1-3 As shown, the stainless steel wire cutting shot grinding machine mainly includes a shot blasting chamber 6 and a first blasting device 1, a second blasting device 2, and a third blasting device 3 installed on the blasting chamber; it also includes a screw conveyor Machine 8, bucket elevator 9, shot slag separator 11, stainless steel wire-cut shot feed port 13, stainless steel wire-cut shot discharge port 14.

[0020] The blasting direction of the first blasting device 1 and the second blasting device 2 is from top to bottom, and the blasting direction of the third blasting device 3 is from right to left. And the projecting lines of the three shot blasters intersect in an area, which is the shot collision area 15 . figure 1 The first blasting device 1 and the second blasting device 2 installed in the center are symmetrical along a vertical line, and the blasting ports of these two blasting devices are on the right side. The third blasting device 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com