Carbonyl ammonium reaction general-purpose enzymolysis solution, preparation method and use thereof

A carbonyl ammonia reaction enzymatic hydrolysis solution, a general-purpose technology, applied in food science and other directions, can solve the problems of high storage cost and ingredient cost, high cost, complex production, etc., and achieve high flavor similarity, high compatibility, and failure rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

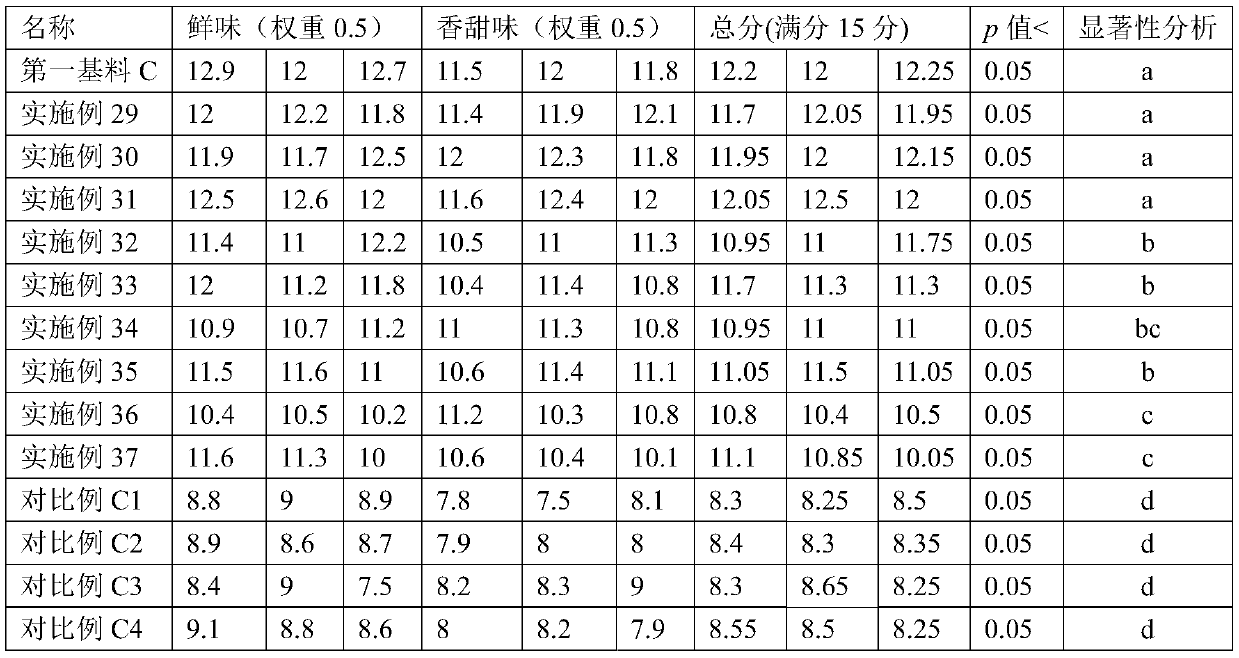

Examples

Embodiment 1

[0082] A general-purpose enzymolysis solution for carbonyl ammonia reaction, the enzymolysis solution is prepared by the following method:

[0083] (1) Mix lean pork stuffing with water, the ratio of solid to water is 1:1, and heat to 50°C;

[0084] (2) add compound enzyme in step (1) gained mixture, carry out enzymolysis according to the ratio of papain: bromelain=2:1, the total amount of compound enzyme added is 0.2% of pork, and the enzymolysis time is 45min;

[0085] (3) Heat the mixture obtained in step (2) to 90° C., and maintain it for 10 minutes to inactivate the enzyme activity, and obtain a general-purpose enzymatic hydrolysis solution for carbonyl ammonia reaction.

[0086] The general-purpose enzymolysis solution contains a first group of amino acids and a second group of amino acids, the first group of amino acids includes 25.18g / L of aspartic acid and 1.52g / L of glutamic acid, and the second group of amino acids Including 1.06g / L serine, 0.85g / L proline, 7.65g / L...

Embodiment 2

[0090] A general-purpose enzymolysis solution for carbonyl ammonia reaction, the enzymolysis solution is prepared by the following method:

[0091] (1) Mix lean pork stuffing with water, the ratio of solid to water is 0.9:1, and heat to 50°C;

[0092](2) add compound enzyme in step (1) gained mixture, carry out enzymolysis according to the ratio of papain: bromelain=1.8:1.1, the total amount of compound enzyme added is 0.2% of pork, and the enzymolysis time is 1h;

[0093] (3) Heat the mixture obtained in step (2) to 80° C., and maintain it for 12 minutes to inactivate the enzyme activity, and obtain a general-purpose enzymatic hydrolysis solution for carbonyl ammonia reaction.

[0094] The general-purpose enzymolysis solution comprises a first group of amino acids and a second group of amino acids. The first group of amino acids includes 23.2 g / L of aspartic acid and 1.22 g / L of glutamic acid. The second group of amino acids Including 1.11g / L serine, 1.03g / L proline, 8.03g / L...

Embodiment 3

[0098] A general-purpose enzymolysis solution for carbonyl ammonia reaction, the enzymolysis solution is prepared by the following method:

[0099] (1) Mix lean pork stuffing with water, the ratio of solid to water is 1.1:1, and heat to 50°C;

[0100] (2) add compound enzyme in step (1) gained mixture, carry out enzymolysis according to the ratio of papain: bromelain=2.2:0.9, the total amount of compound enzyme added is 0.2% of pork, and the enzymolysis time is 1h;

[0101] (3) Heat the mixture obtained in step (2) to 110° C. and maintain it for 8 minutes to inactivate the enzyme activity to obtain a general-purpose enzymatic hydrolysis solution for carbonyl ammonia reaction.

[0102] The general-purpose enzymolysis solution contains a first group of amino acids and a second group of amino acids, the first group of amino acids includes 22.7g / L of aspartic acid and 1.00g / L of glutamic acid, and the second group of amino acids Including 0.8g / L serine, 0.45g / L proline, 6.65g / L g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com