Ventilation tower-type lower air-inlet gas cooker

A technology for gas stoves and air intake, applied to burners, combustion methods, heating fuels, etc., can solve the problems of non-concentrated, non-violent, uneven firepower, etc., and achieve the goal of reducing heat loss and increasing heat transfer temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described

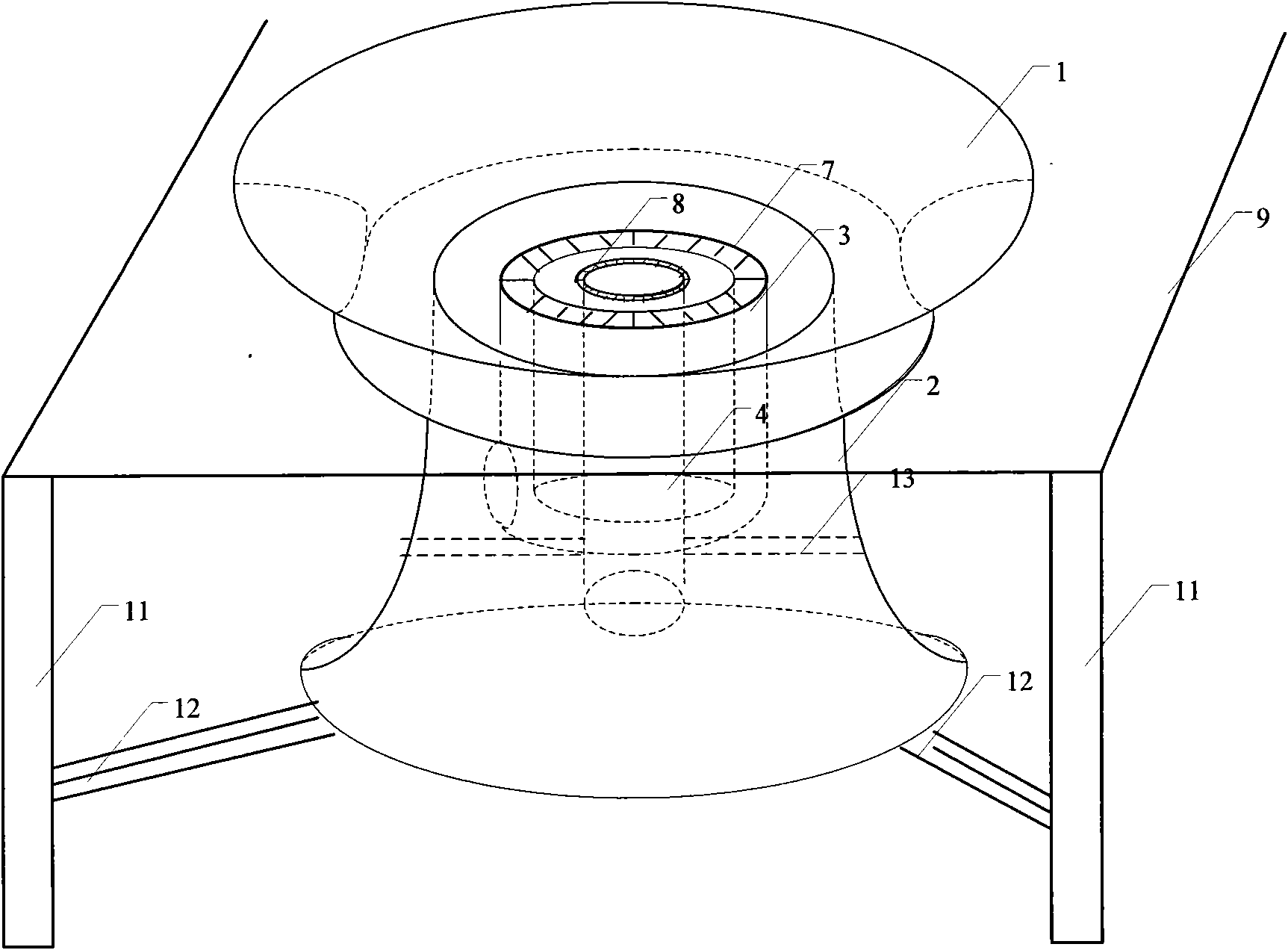

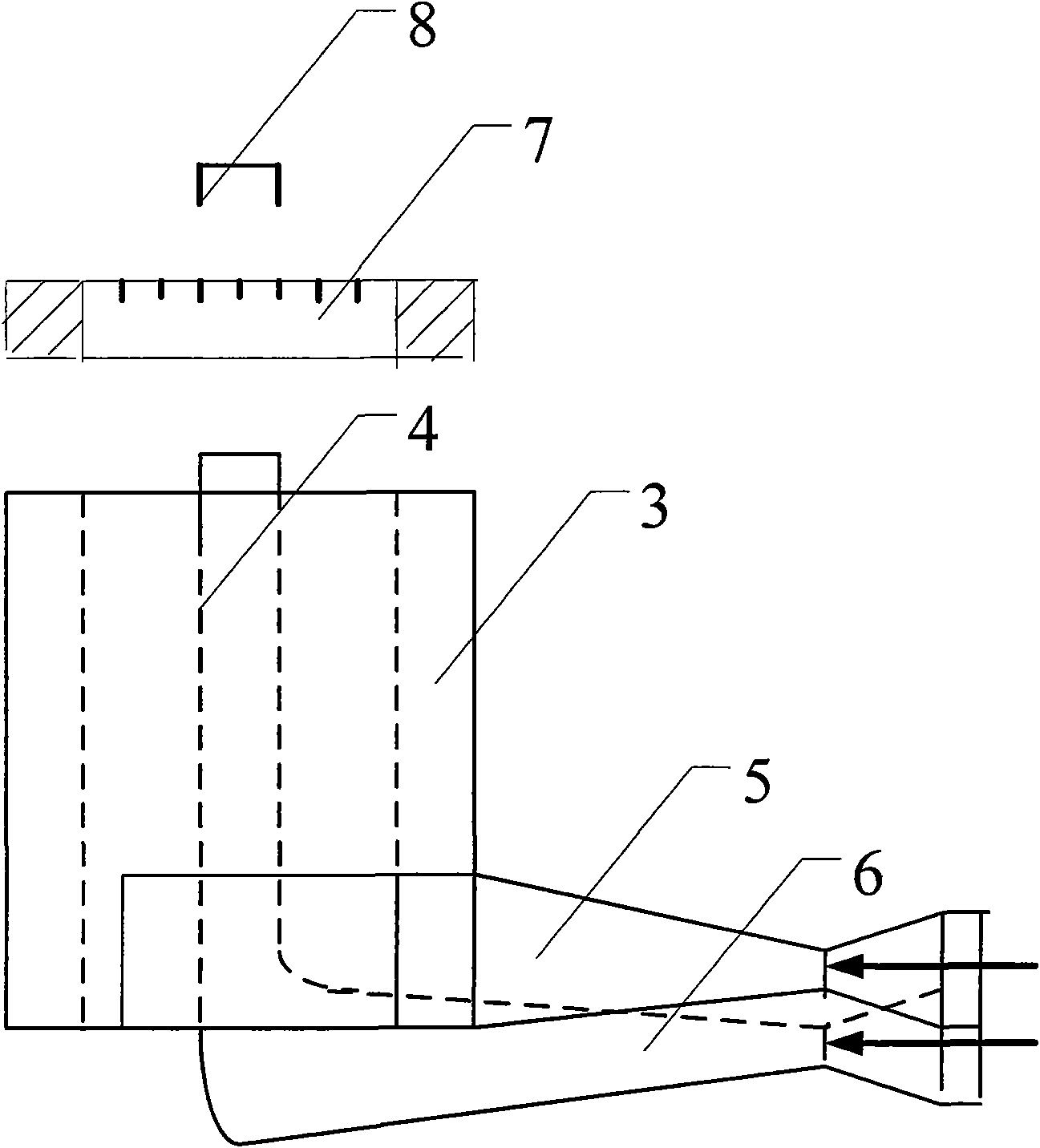

[0021] Ventilation tower type lower air inlet gas cooker, comprises the hyperbolic guide tube (1) that is fixed on the cooktop panel (9); Furnace hearth (2) is installed at the lower end of hyperbolic guide tube (1); Furnace hearth ( 2) There is a burner inside, and the burner is composed of two combustion heads, that is, the annular combustion head composed of the outer mixing chamber (3) and the annular fire cover (7) and the inner mixing chamber (4) and the fire cover (8) The circular combustion head; the ejector (5) is connected to the outer mixing chamber (3) in the tangential direction at the lower end of the outer mixing chamber (3) to form a whole; the ejector (6) is connected to the lower end of the inner mixing chamber (4) to form a overall. The annular combustion head and the circular combustion head of the hyperbolic draft tube (1), the furnace (2), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com