Steel plates for cargo hold of coal/ore carrier

A technology for transporting ships and ores, applied in the direction of metal rolling, etc., can solve problems that have not yet been established, achieve good collision safety, prevent rolling cracks, and reduce water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

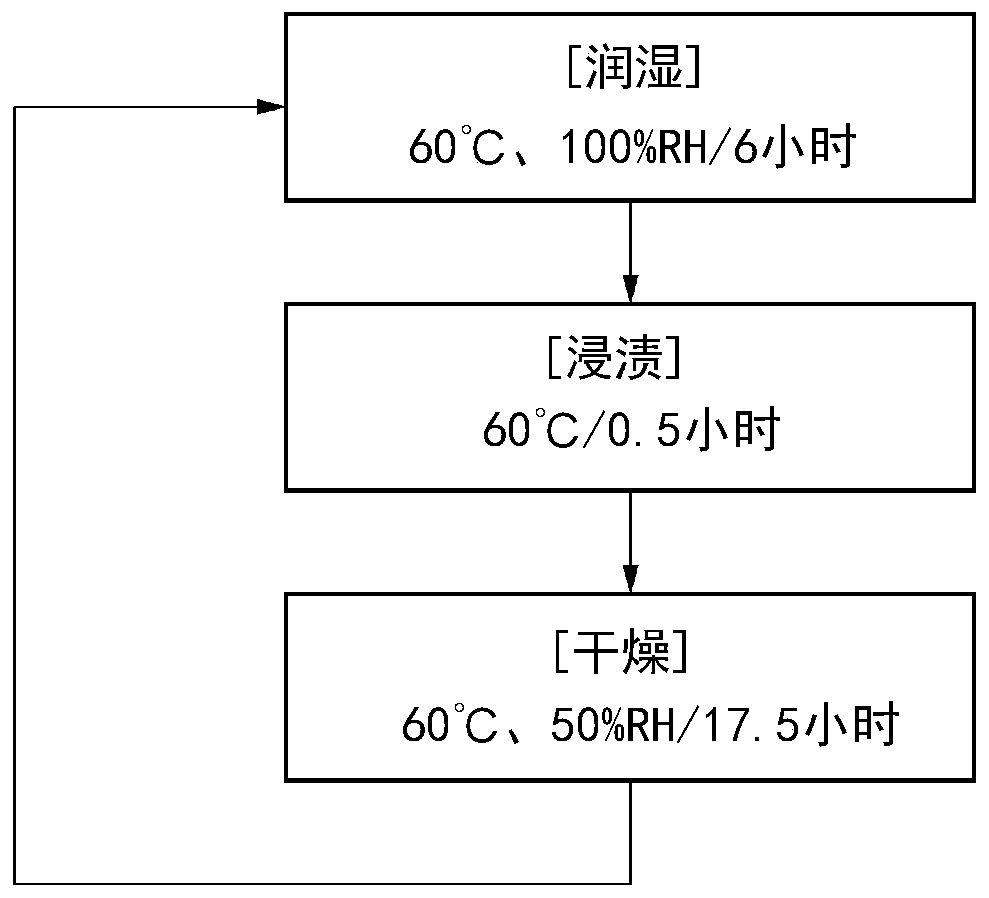

Method used

Image

Examples

Embodiment

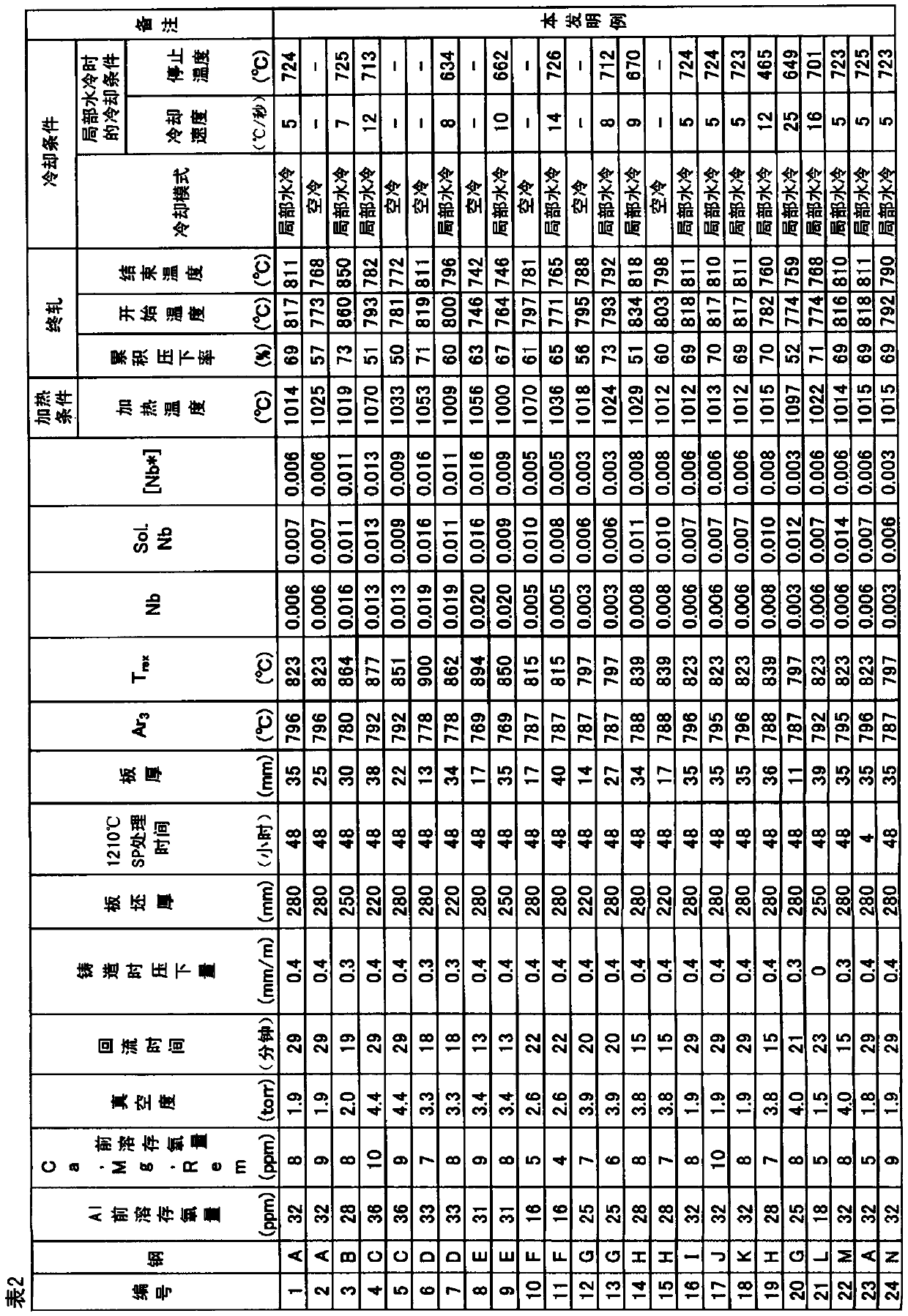

[0149] Hereinafter, examples of the present invention will be described with reference to Tables 1-4.

[0150] Steel sheets having a thickness of 6 to 40 mm were trial-manufactured under the production conditions of Tables 2 and 3 using steel slabs having the chemical components shown in Table 1. In addition, the amount of dissolved oxygen before Ca, Mg, and REM in Tables 2 and 3 means before adding one or more of Ca, Mg, and REM. dissolved oxygen through the use of ZrO 2 (MgO) solid electrolyte oxygen concentration cell oxygen probe inserted into molten steel to measure. The reflow time is the time from the addition of Al as a deoxidizer to the addition of Ca, Mg, and REM. The reduction during casting is the reduction (mm / m) when the central solidification rate is 0.2 to 0.7. Ar 3 Calculated from formula (1), T rex It can be obtained from formula (2), and [Sol.Nb] can be obtained from formula (3). The cooling rate (° C. / sec) in the cooling condition column is the cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com