Ultraviolet light irradiation crosslinking device, light irradiation wire and production method thereof

A cross-linking device and ultraviolet light technology, which is applied in the direction of circuits, electrical components, insulated cables, etc., can solve the problems of wire quality, low irradiation intensity, inconsistency of insulation layer flexibility and tensile strength, etc., to prolong the service life , UV light source is uniform, and the effect of speeding up the speed of smoke escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

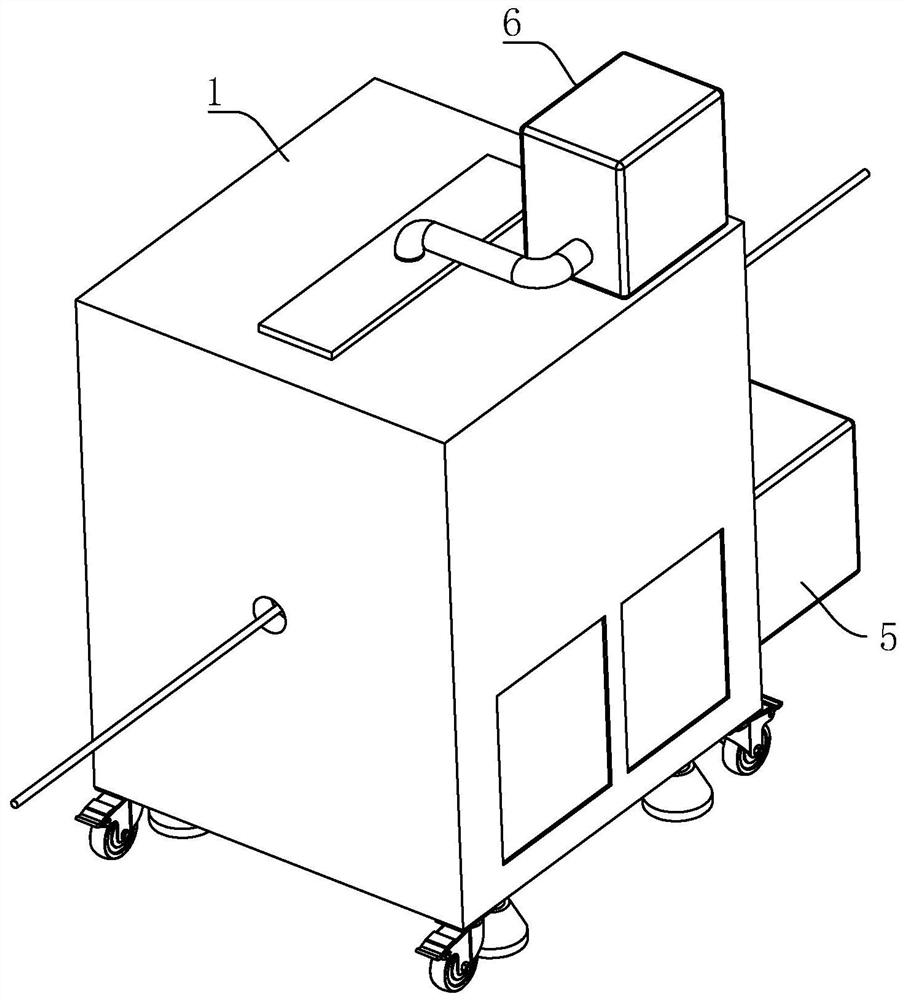

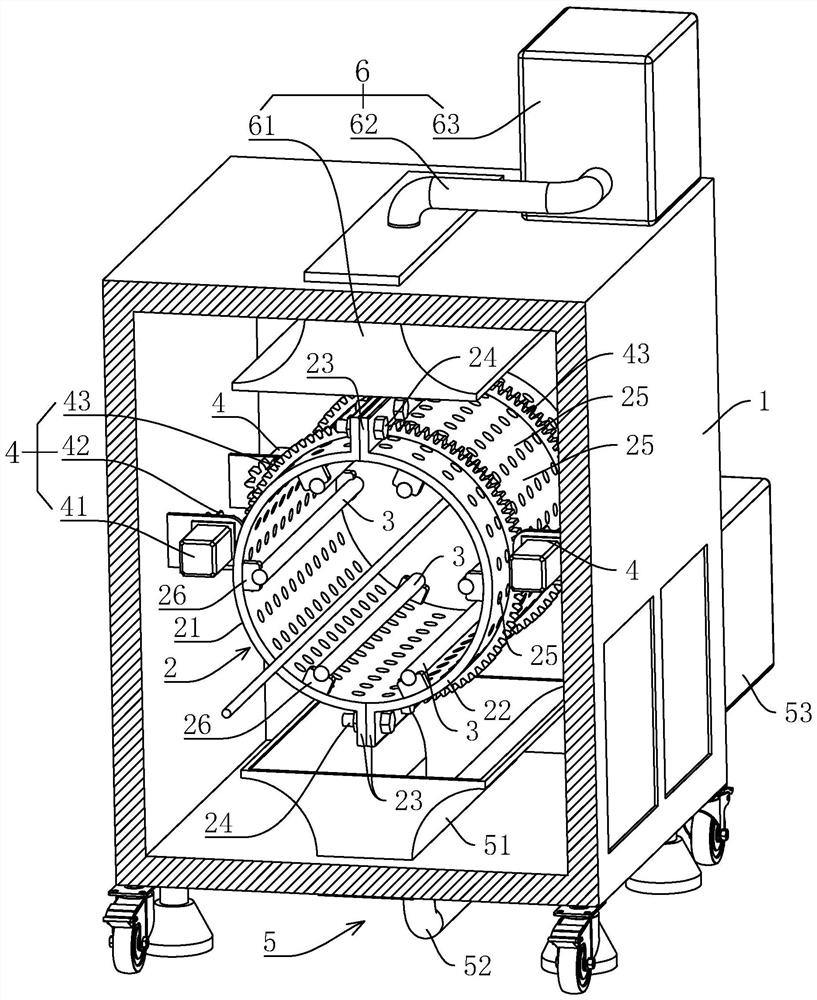

[0047] refer to figure 1 and figure 2 , is an ultraviolet radiation cross-linking device disclosed in the present invention, comprising: a chassis 1, an irradiation cylinder 2, an ultraviolet light source 3, a drive assembly 4, an air supply assembly 5 and an exhaust assembly 6.

[0048] The irradiation tube 2 is arranged in the cabinet 1, and the cabinet 1 is provided with a wire inlet and a wire outlet, and the wire passes through the center of the irradiation tube 2, and a plurality of ultraviolet light sources 3 are fixed on the inner wall of the irradiation tube 2, and the arrangement direction of the ultraviolet light source 3 is Consistent with the wire threading direction, a plurality of ultraviolet light sources 3 are evenly spaced and arranged in a circle, and the driving assembly 4 is arranged between the inner wall of the cabinet 1 and the outer wall of the irradiation tube 2, and the driving assembly 4 is used to drive the irradiation tube 2 , The ultraviolet li...

Embodiment 2

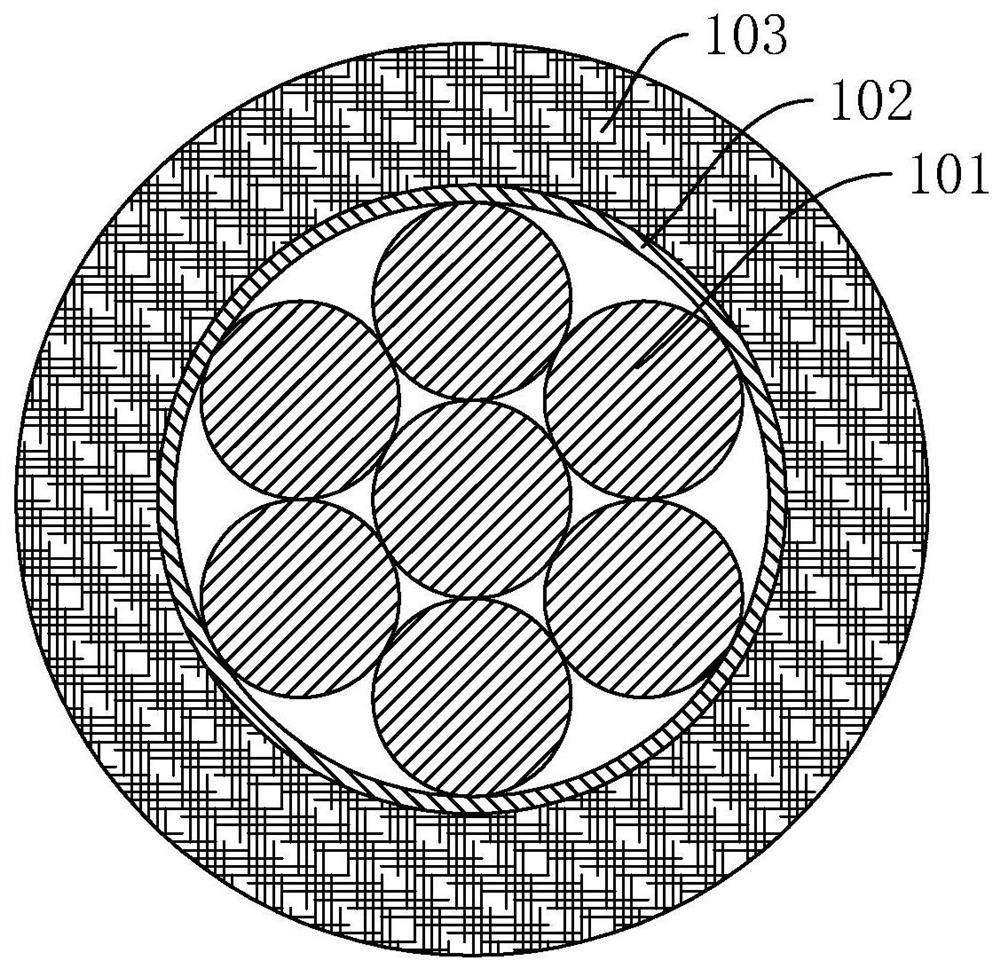

[0060] refer to figure 2 and image 3 , is a light radiation wire disclosed in the present invention, comprising: a conductor 101, a reflective silver paper layer 102 and an insulating layer 103, and the light radiation wire passes through the ultraviolet radiation crosslinking device as described in Embodiment 1 during production, The ultraviolet light irradiation crosslinking device performs ultraviolet light treatment on the insulating layer 103 . The insulating layer 103 is treated with ultraviolet light by using the above-mentioned ultraviolet irradiation cross-linking device, the insulating layer 103 is not easy to have local inconsistencies in flexibility and tensile strength, and the quality of the light radiation wire is better; when the insulating layer 103 is irradiated by ultraviolet light , the reflective silver paper layer 102 also has a certain reflective effect, so that the ultraviolet light will be reflected more thoroughly between the molecules of the insul...

Embodiment 3

[0062] refer to image 3 and Figure 4 , is a production method of optical radiation wires disclosed in the present invention, based on the ultraviolet light irradiation crosslinking device described in Embodiment 1, the production method includes: S1: stranding a plurality of copper wires into a conductor 101; S2: Wrap the reflective silver paper tape on the surface of the conductor 101, and the reflective silver paper tape is in a spiral shape and wraps the conductor 101 to form the reflective silver paper layer 102; S3: Extrude the hot-melted polyethylene material on the outer periphery of the reflective silver paper layer 102 wall to form an insulating layer 103 to produce a semi-finished wire; S4: transport the semi-finished wire to an ultraviolet light irradiation cross-linking device for ultraviolet light treatment, and then carry out a water cooling treatment after the wire semi-finished product is output from the ultraviolet radiation cross-linking device to produce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com