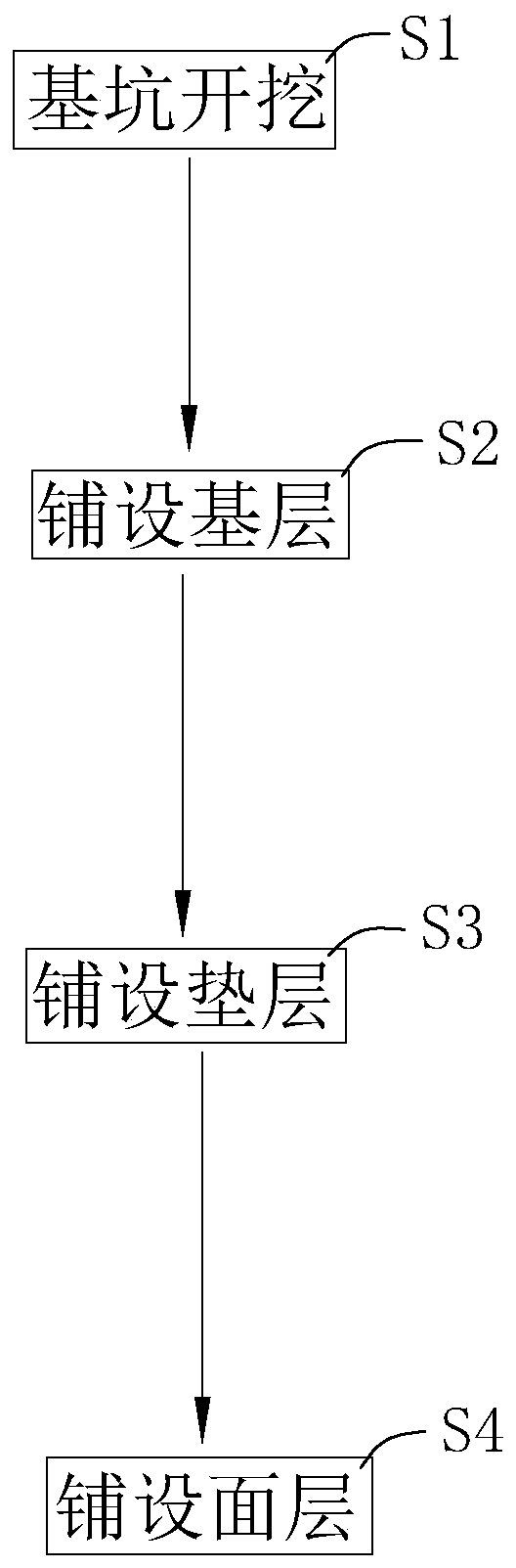

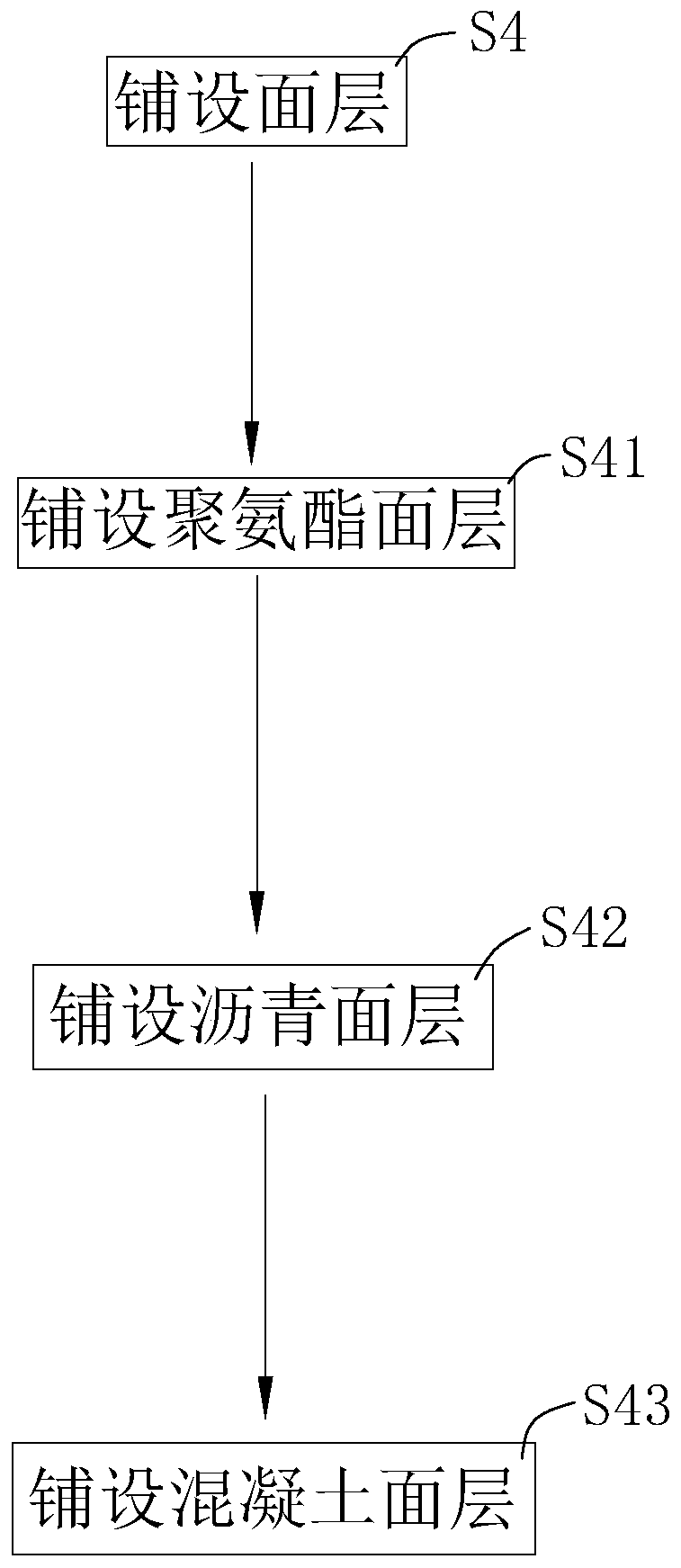

Municipal road construction method

A construction method and technology for municipal roads, applied in the directions of roads, roads, buildings, etc., can solve problems such as the decline of soil structure strength, the decline of supporting road stability, road collapse, etc., to achieve enhanced frost resistance, reduced impact, and less icing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A kind of concrete slurry, the preparation method of concrete slurry is as follows:

[0073] a. Add 100kg of Portland cement, 90kg of water, and 11kg of water reducing agent into the stirring tank at a speed of 60r / min, and stir for 5min to form cement slurry;

[0074] b. Add 5kg of silane coupling agent and 100kg of polyurethane adhesive to the cement slurry at a speed of 60r / min and stir for 5min to form a premix;

[0075] c. Add 300kg of coarse aggregate and 150kg of fine aggregate to the premix, rotate at 45r / min, and stir for 8min to form concrete slurry.

Embodiment 2

[0077] A kind of concrete slurry, the preparation method of concrete slurry is as follows:

[0078] a. Add 100kg of Portland cement, 100kg of water, and 10kg of water reducing agent into the stirring tank at a speed of 60r / min, and stir for 5min to form cement slurry;

[0079] b. Add 7.5kg of silane coupling agent and 125kg of polyurethane adhesive to the cement slurry at a speed of 60r / min and stir for 5min to form a premix;

[0080] c. Add 350kg of coarse aggregate and 175kg of fine aggregate to the premix, rotate at 45r / min, and stir for 8min to form concrete slurry.

Embodiment 3

[0082] A kind of concrete slurry, the preparation method of concrete slurry is as follows:

[0083] a. Add 100kg of Portland cement, 110kg of water, and 9kg of water reducing agent into the stirring tank at a speed of 60r / min, and stir for 5min to form cement slurry;

[0084] b. Add 10kg of silane coupling agent and 150kg of polyurethane adhesive to the cement slurry at a speed of 60r / min and stir for 5min to form a premix;

[0085] c. Add 400kg of coarse aggregate and 200kg of fine aggregate to the premix, rotate at 45r / min, and stir for 8min to form concrete slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com