Antibacterial temperature-controlled micro-nano fiber and preparing method thereof

A micro-nano fiber and antibacterial technology, which is applied in the field of antibacterial temperature-controlled micro-nano fibers and their preparation, can solve the problems of uninvolved intelligent responsiveness of fibers, poor order of micro-nano fibers, and difficult operation, etc. effect, good compatibility, and the effect of improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

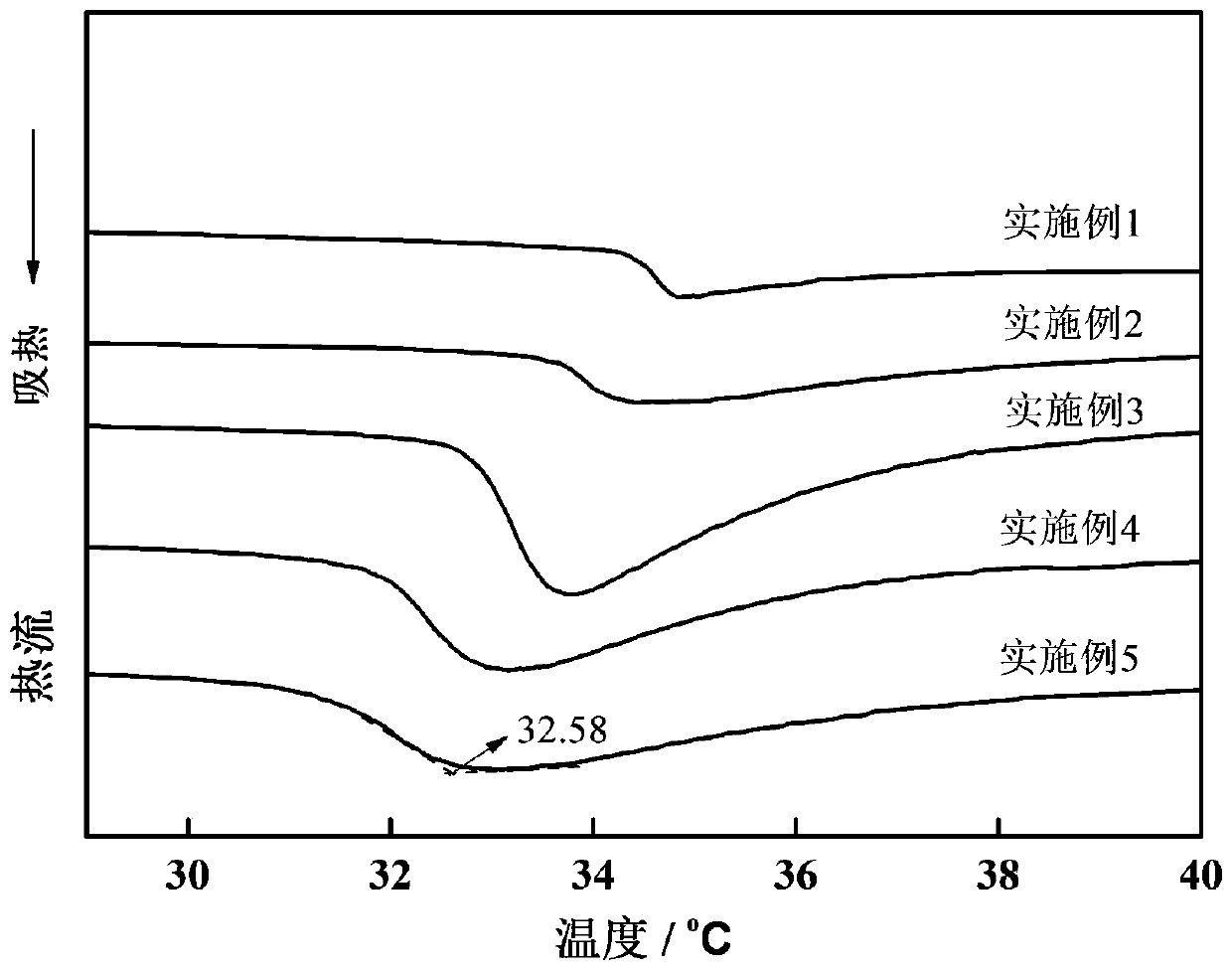

Examples

preparation example Construction

[0036] In the present invention, the preparation method of the modified sericin solution preferably includes the following steps:

[0037]Under the protection of oxygen, the sericin aqueous solution is mixed with tyrosinase, and the enzyme-catalyzed oxidation reaction is carried out to obtain the sericin quinone solution;

[0038] The sericin quinone solution is mixed with the cecropin antimicrobial peptide to obtain the modified sericin solution.

[0039] In the invention, under the protection of oxygen, the sericin aqueous solution is mixed with tyrosinase, and the enzyme-catalyzed oxidation reaction is carried out to obtain the sericin quinone solution.

[0040] In the present invention, the concentration of the sericin aqueous solution is preferably 10-20 wt%, more preferably 12-18 wt%, more preferably 14-16 wt%; the dosage of the tyrosinase is preferably 2000-4500 U / g , more preferably 2500 to 4000 U / g, more preferably 3000 to 3500 U / g.

[0041] In the present invention...

Embodiment 1

[0059] Preparation of modified sericin solution

[0060] Under the condition of oxygen protection and temperature at 25°C, 90mL of 10% sericin aqueous solution by mass and tyrosinase (2000U / g) enzyme catalyzed oxidation reaction for 30min. and the antimicrobial peptides are mixed and stirred under certain conditions to obtain a modified sericin solution.

[0061] Preparation of spinning dope

[0062] Under the condition of nitrogen protection, 1 mL of the above-mentioned modified sericin solution, 0.5 g of N-isopropylacrylamide, 0.04 g of N,N-methylenebisacrylamide, 0.05 g of ammonium persulfate and 2.0 mL of N,N, N,N-Tetramethylethylenediamine was mixed with 10 mL of 2% acetic acid, and subjected to free radical polymerization at 60°C for 4 hours to obtain an antibacterial thermosensitive hydrogel.

[0063] Mix the antibacterial thermosensitive hydrogel with 10% by mass polyethylene oxide (relative molecular mass: 40kDa) aqueous solution according to the volume ratio of 1:5...

Embodiment 2

[0069] Preparation of modified sericin solution

[0070] Under the condition of oxygen protection and temperature at 35°C, 90mL of 15% sericin aqueous solution by mass percentage and tyrosinase (3000U / g) enzyme catalyzed oxidation reaction for 45min. and the antimicrobial peptides are mixed and stirred under certain conditions to obtain a modified sericin solution.

[0071] Spinning dope preparation

[0072] Under the condition of nitrogen protection, 1 mL of the above-mentioned modified sericin solution, 0.5 g of N-isopropylacrylamide, 0.04 g of N,N-methylenebisacrylamide, 0.05 g of ammonium persulfate and 2.0 mL of N,N, N,N-Tetramethylethylenediamine was mixed with 10 mL of 2% acetic acid for free radical polymerization to obtain an antibacterial thermosensitive hydrogel.

[0073] Mix the antibacterial thermosensitive hydrogel with 10% by mass polyethylene oxide (relative molecular mass: 40kDa) aqueous solution according to the volume ratio of 2:5, stir at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com