Mold processing method based on gypsum sand self-hardening molding

A processing method and molding technology, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of difficult regeneration of old sand, high comprehensive cost, large solid waste discharge, etc., and achieve simple molding production process and solve Difficult to disintegrate, excellent disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

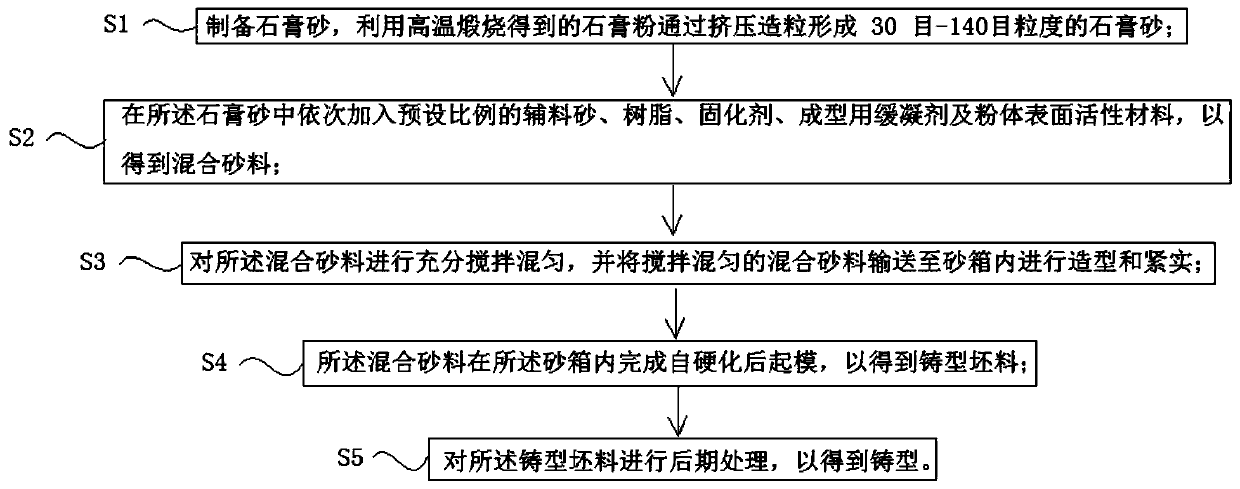

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the casting mold processing method based on gypsum sand self-setting molding provided by the present invention.

[0027] In a specific embodiment, this patent technology refers to high-strength gypsum powder calcined at high temperature (containing α-type hemihydrate gypsum or β-type hemihydrate gypsum) through professional extrusion granulation to form 30 mesh-140 mesh high For high-strength gypsum sand, add a certain proportion of other foundry sand, resin, curing agent, retarder and powder surface active materials according to the material and use requirements of the casting and add them in sequence to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com