Preparation method of SCM-15 molecular sieves and application of molecular sieves to adsorption of volatile organic gas

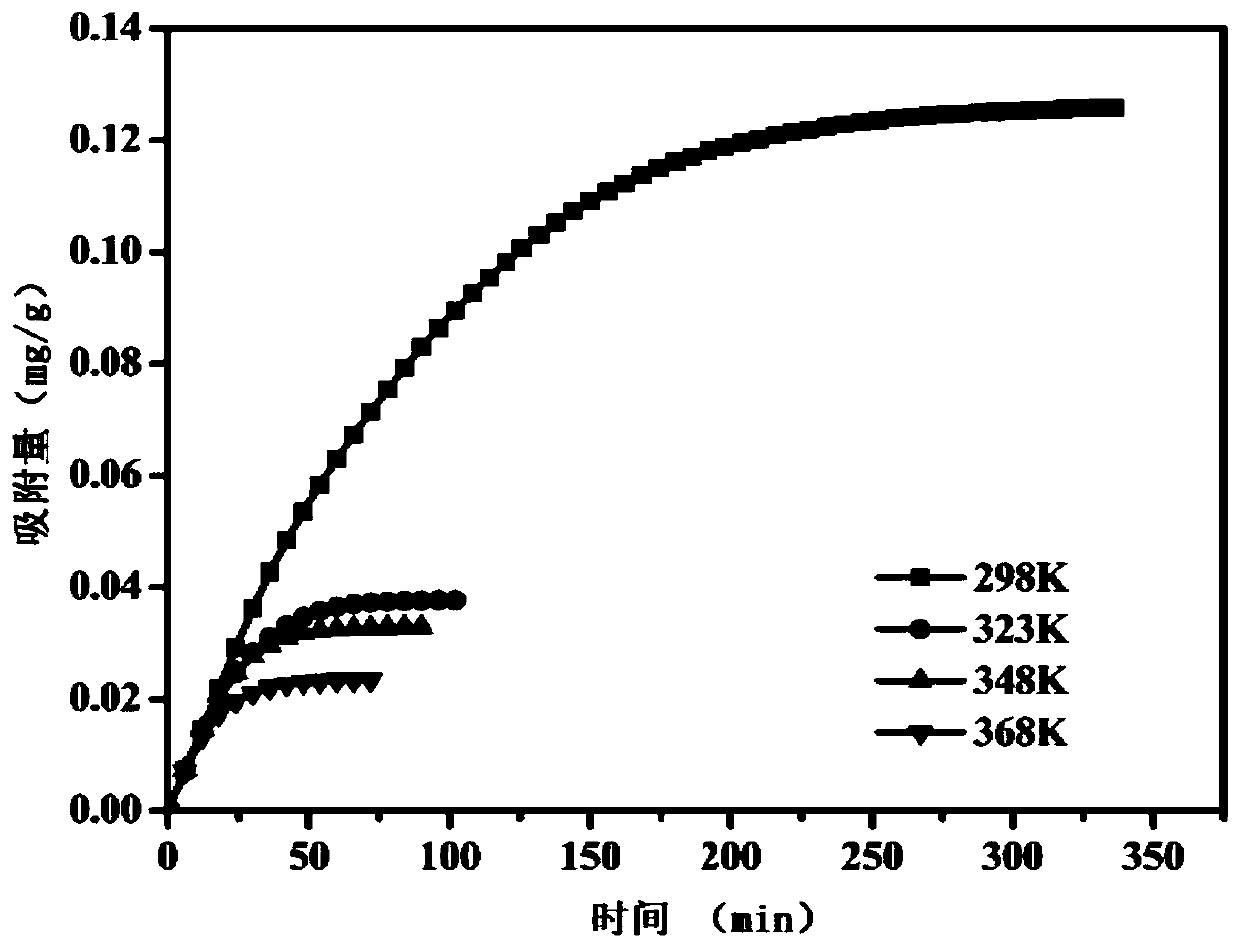

A volatile organic and gas adsorption technology, which is applied in the field of preparation of SCM-15 molecular sieve, can solve the problems of less research on the application of VOCs adsorption, and achieve the effect of high solid phase yield, good adsorption effect and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

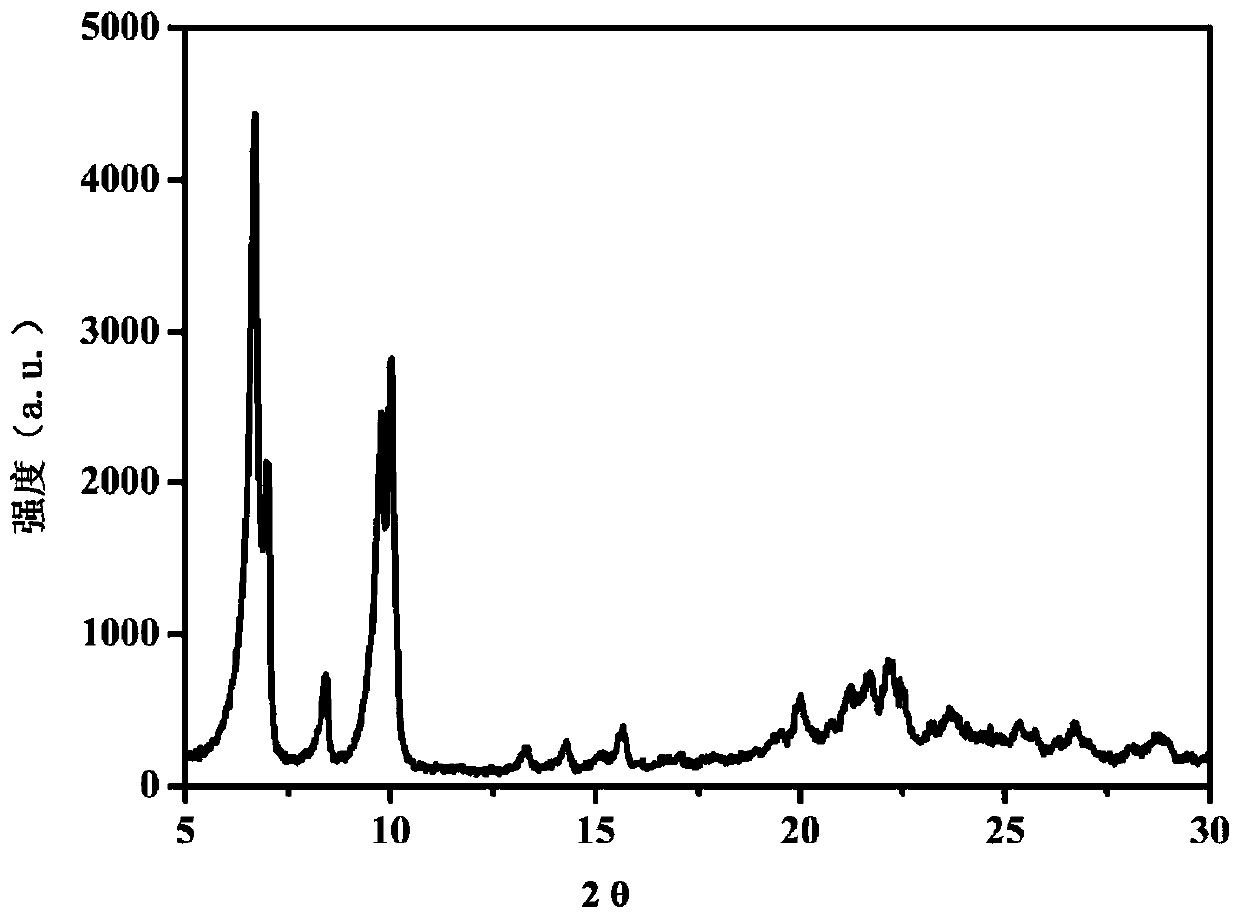

[0023] Preparation process of SCM-15 molecular sieve: Weigh 4.55g of template agent and 1.05g of germanium dioxide respectively, dissolve them in 4ml of deionized water, stir well until completely dissolved; weigh 7.5g of silica sol and add to the above solution drop by drop, at room temperature Stir for 30 minutes, then add 0.73 g of tetrahydrofuran, and stir thoroughly for 30 minutes to obtain a mixed solution; weigh 1.5 g of hydrofluoric acid and slowly add to the above mixed solution, and stir for 1 hour to obtain a uniform gel mixture. The obtained homogeneous gel mixture was transferred to a stainless steel autoclave with a polytetrafluoroethylene liner, and crystallized at 180 ° C for 6 days under static conditions; naturally cooled to room temperature, the solid phase product was recovered by filtration, and the Washed with deionized water several times, then dried overnight at 100°C, and finally calcined in a muffle furnace at 550°C for 5 hours to finally obtain SCM-15...

Embodiment 2

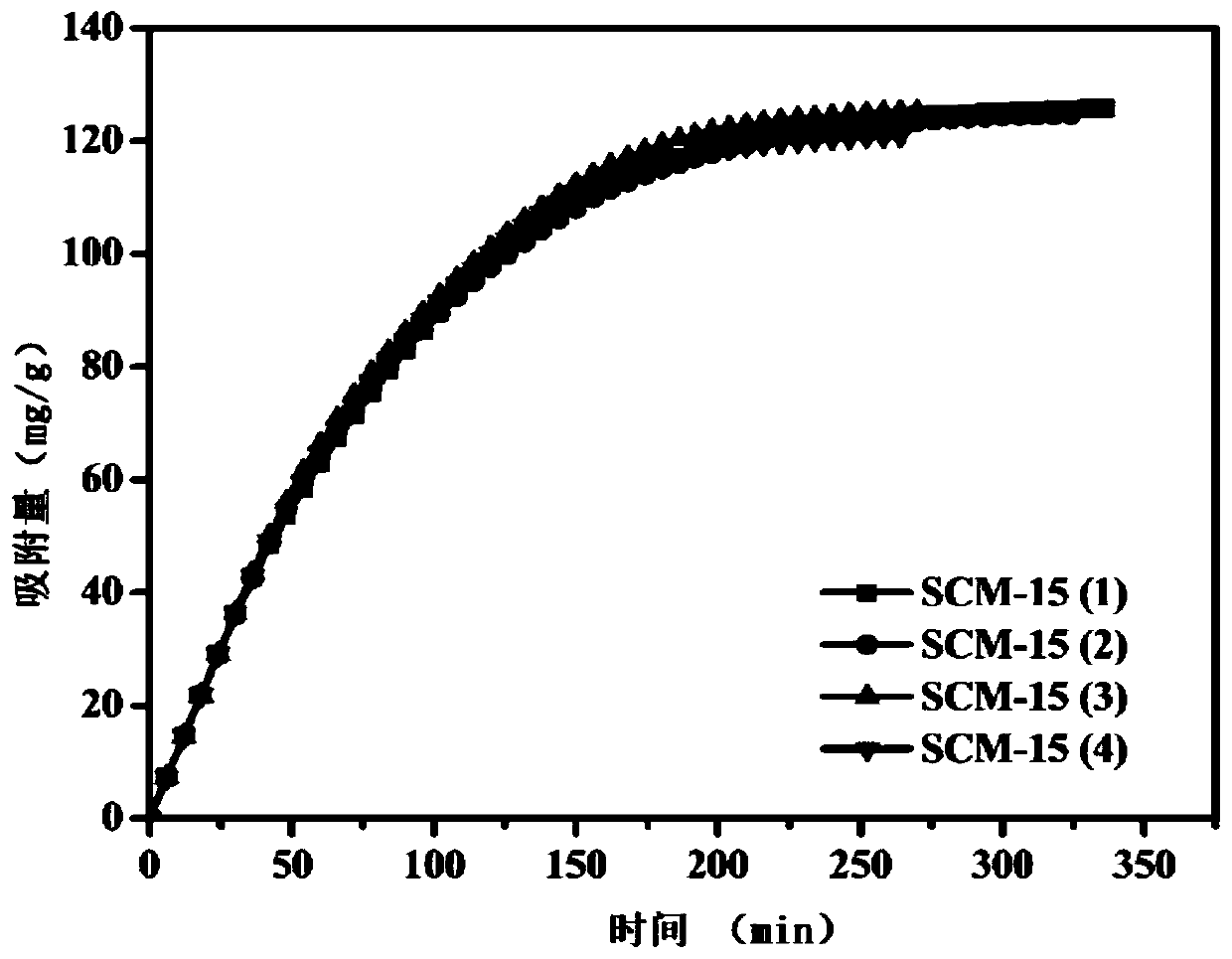

[0025] The basic steps for the preparation of SCM-15 molecular sieve are the same as in Example 1, except that the molar ratio of tetrahydrofuran to silicon dioxide is changed from 0.2 to 0.5 and 0.9, and finally SCM-15 molecular sieve is obtained.

Embodiment 3

[0027] The basic steps for the preparation of SCM-15 molecular sieve are the same as in Example 1, except that the crystallization condition is changed from crystallization at 180°C for 6 days to crystallization at 160°C for 6 days, and finally SCM-15 molecular sieve is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com