A method for making a mosaic panel with various inlaid materials

A production method and technology for flower boards, which are applied in the directions of wood impregnation, manufacturing tools, wood processing, etc., can solve the problems of inconvenient installation of inlays and difficult processing of inlaid grooves, so as to improve product value, show texture and color, and ensure smoothness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

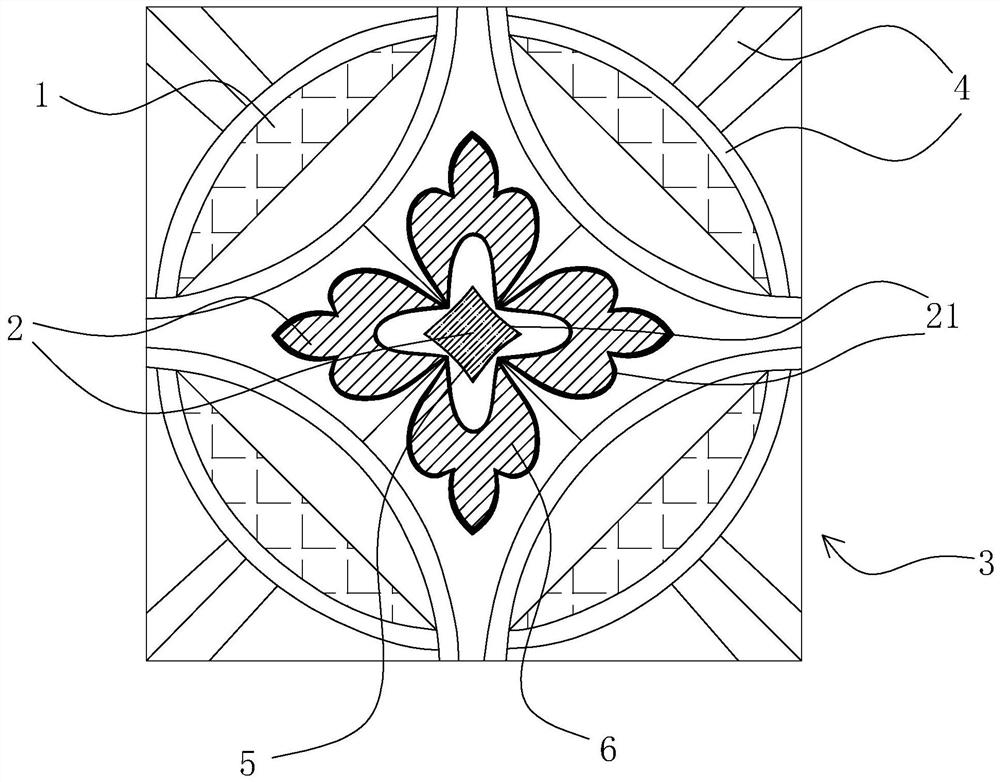

[0046]combine Figure 1-6 , a mosaic board with various inlay materials, including cloisonné inlay 1, hand-polished inlay 2, dyed wood board 3 and dyed veneer 4; wherein hand-polished inlay 2 includes lacquer painting inlay 5 and glazed inlay 6.

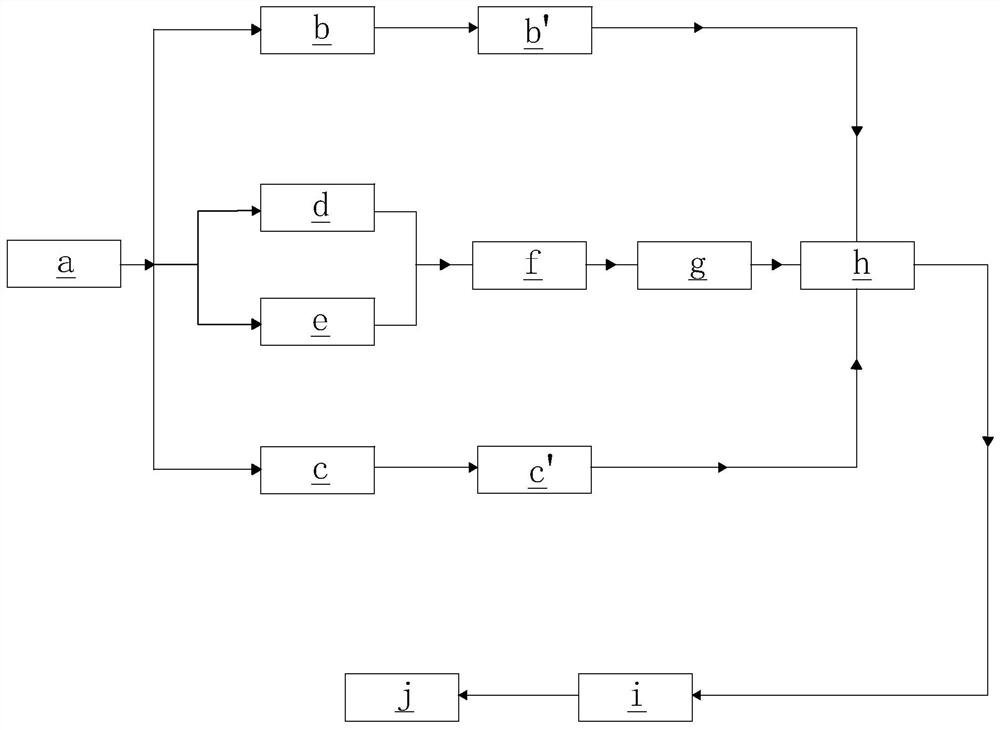

[0047] The method for making a mosaic panel with various mosaic materials comprises the following steps,

[0048] A. Design the plan and determine the product size, material and color: design the plan and determine the product size and material, and make CAD drawings for the product. According to the CAD drawing, make a color rendering and decompose the drawing. At the same time, the specific process and precautions of each process in the production are marked.

[0049] B. Make cloisonné inserts 1 and anti-warping structures 11, make and trim hand-polished inserts 2, trim and make metal positioning strips 21:

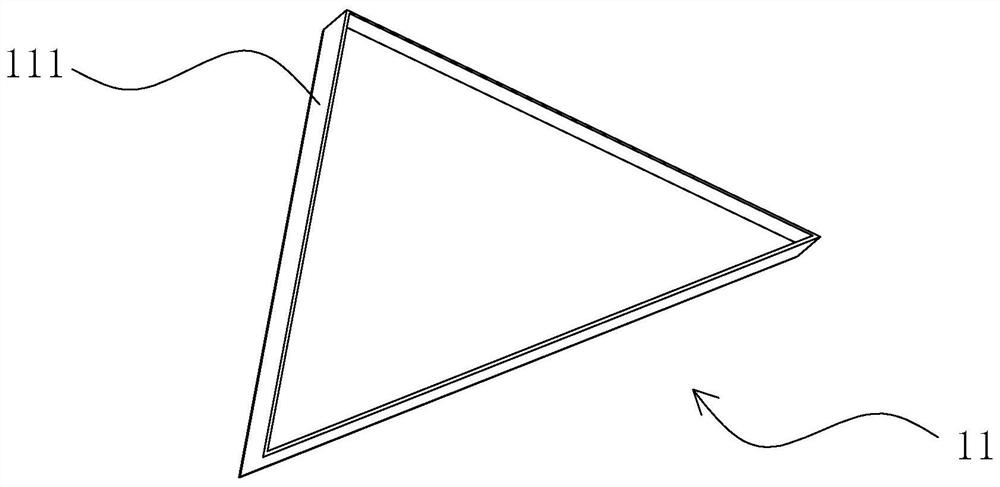

[0050] The manufacturing method of the cloisonné insert 1 and the anti-warping structure 11 comprises the following steps...

Embodiment 2

[0101] combine Figure 2-7 , a mosaic board with various inlay materials, including cloisonne inlay 1, hand-polished inlay 2, dyed wood board 3 and dyed veneer 4; wherein the hand-polished inlay 2 is glazed inlay 6.

[0102] The method for making the mosaic board with various mosaic materials is roughly the same as that in Example 1, except that step F:

[0103] When inlaying the cloisonné insert 1, if the cloisonné insert 1 has a transparent part, several small diamonds can be bonded with an adhesive in advance just below the transparent part, so that the small diamonds can be observed through the cloisonné insert 1 To improve the overall aesthetics, the thickness of the adhesive injected into the cloisonne precision inlay groove 12 is 1.08mm, that is, the actual amount of adhesive added is 8% higher than the theoretical amount;

[0104] When inlaying the hand-polished inlay 2, since it is a glazed inlay 6, add transparent glue or white glue that conforms to the material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com