A high-throughput preparation and heat treatment method of a ternary diffusion couple

A diffusion couple, high-throughput technology, applied in the direction of metal rolling, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of low efficiency, low success rate, high cost, etc., to achieve firm combination, shorten time, and work efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: High-throughput preparation of Cu-Au-Ag diffusion couples

[0039] (1) Prepare pure metal strips, see Table 1 for specific dimensions

[0040]

[0041] (2) Surface grinding, pickling, rinsing and drying of the prepared strip.

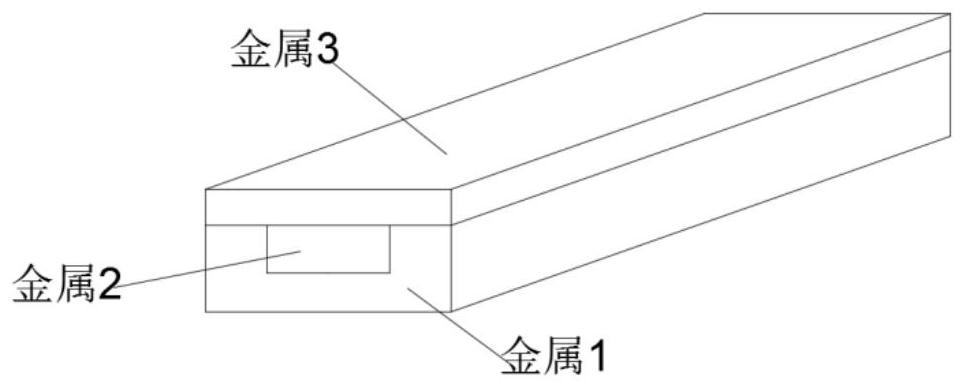

[0042] (3) Strip positioning: the Au strip is embedded in the Cu groove, and the Ag strip covers the surface of the Cu strip and completely covers the Au strip.

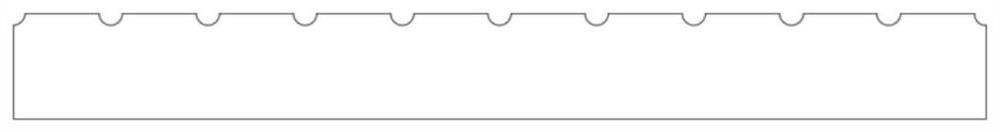

[0043] (4) Cold composite rolling: The positioned strips are composite rolled with a special cold composite rolling mill, with a single-pass deformation of 75%, so that the three strips can be mechanically occluded and firmly combined.

[0044] (5) Sample interception and marking: select a well-bonded composite strip with a length of 30 cm, and mark a line every 10 mm on the edge of the composite strip.

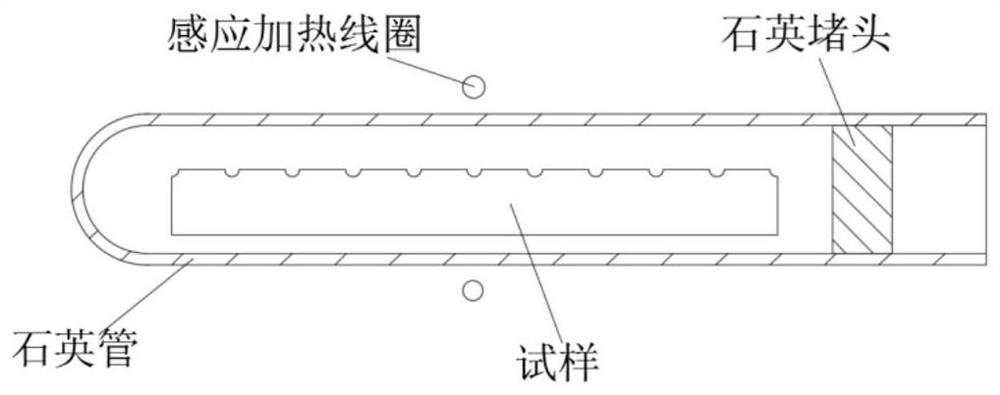

[0045] (6) Vacuum sealing: place the intercepted composite strip in a 40 cm long quartz tube, first vacuumize it, and then seal it with a special sealing machine for qu...

Embodiment 2

[0048] Example 2: High-throughput preparation of Cu-Ag-Ni diffusion couples

[0049] (1) Prepare pure metal strips, see Table 2 for specific dimensions.

[0050] Table 2

[0051]

[0052] (2) Surface grinding, pickling, rinsing and drying of the prepared strip.

[0053] (3) Hot compound rolling: Hot compound rolling is carried out with a special hot compound rolling mill. The hot compound temperature is 600°C, the compound speed is 1.5m / min, the protective atmosphere is an ammonia decomposition atmosphere, and the deformation in a single pass is 55%. Under the action of temperature, the three metals have certain metallurgical bonding.

[0054] (4) Sample interception and marking: select a well-bonded composite strip with a length of 32 cm, and mark a line every 8 mm on the edge of the composite strip.

[0055] (6) Vacuum sealing: place the intercepted composite strip in a 40 cm long quartz tube, first vacuumize it, and then seal it with a special sealing machine for quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com