Method for preparing core-shell type silicon/carbon composite material through in-situ carbon coating and application of core-shell type silicon/carbon composite material

A carbon composite material, core-shell type technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of difficult to achieve the level of practical application, high production cost, low output, etc., to achieve mass production, ratio High capacity, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

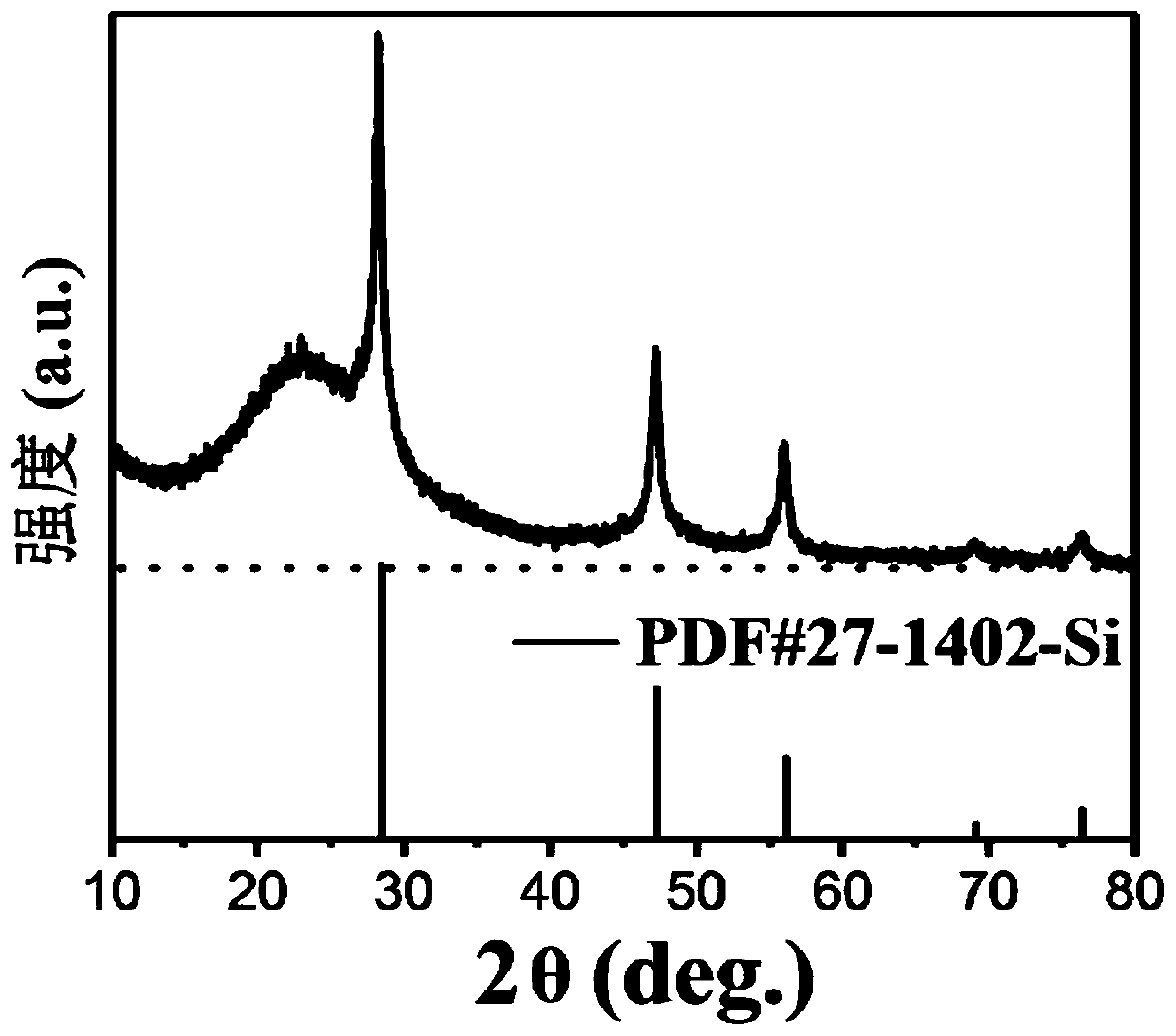

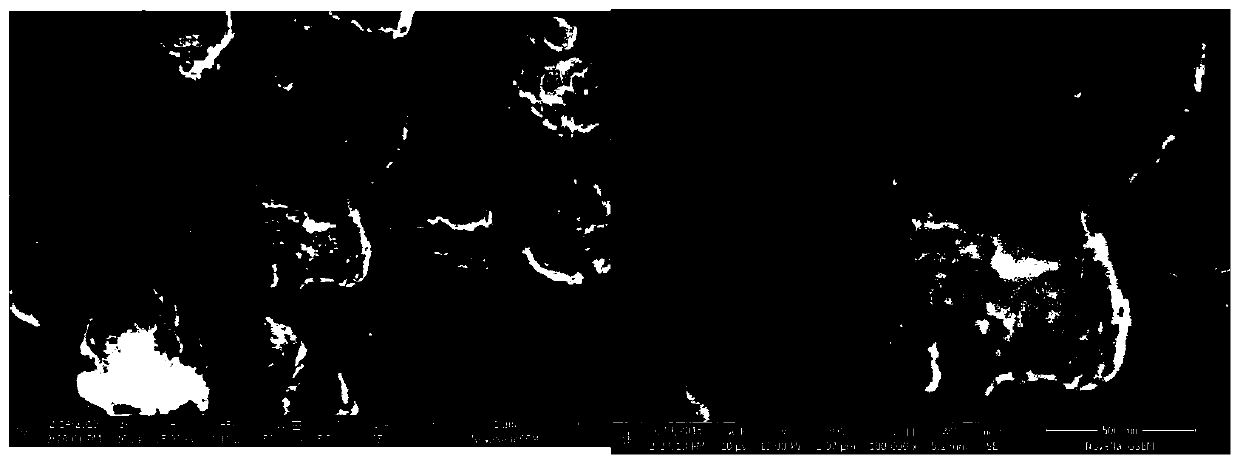

[0025] Grind 5g of micron silicon powder and 0.5g of lithium carbonate evenly, put them into a closed heating tube to evacuate, then heat up to 650°C at a heating rate of 5°C / min for reaction, and the holding time is 10h; after the reaction, cool to room temperature. The product was successively soaked in 1M dilute hydrochloric acid for 3 hours, soaked in 10% hydrofluoric acid for half an hour, washed with deionized water and alcohol three times. Then, it was filtered by suction and dried in vacuum at 80° C. to obtain a core-shell silicon / carbon composite material. figure 1 It is the XRD diffraction pattern of the composite material, compared with the standard card, it is elemental silicon. figure 2 It is the SEM picture of the composite material. It can be seen that the product is a silicon / carbon composite material with a core-shell structure with a layer of carbon coating on the surface of silicon powder.

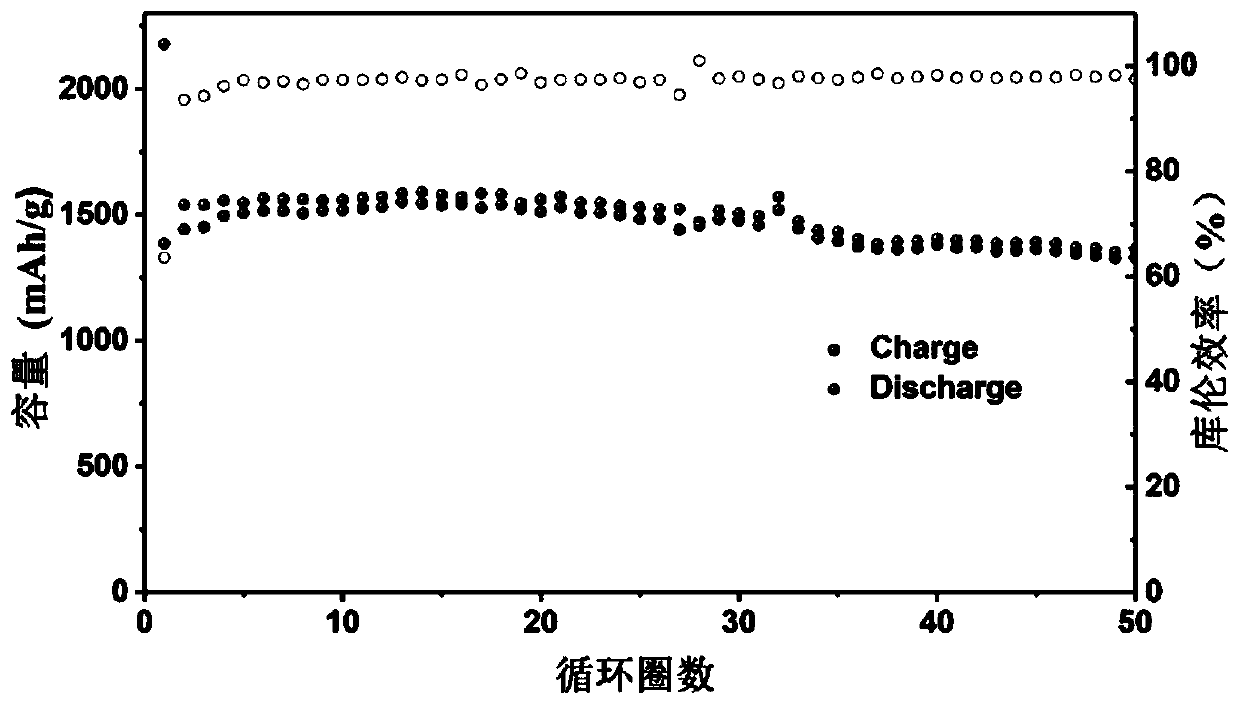

[0026] The core-shell silicon / carbon composite material prepared...

Embodiment 2

[0029] Grind 8g of nano-silicon powder and 1g of lithium carbonate evenly, put them into a closed heating tube to evacuate, then heat to 500°C at a heating rate of 5°C / min for reaction, and the holding time is 10h; after the reaction, cool to room temperature . The product was successively soaked in 1M dilute hydrochloric acid for 3 hours, soaked in 10% hydrofluoric acid for half an hour, washed with deionized water and alcohol three times. Then, it is filtered by suction and dried under vacuum at 80° C. to obtain a core-shell silicon / carbon composite material.

Embodiment 3

[0031] Grind 10g of silicon / aluminum alloy powder and 2g of lithium carbonate evenly, put them into a closed heating tube to evacuate, and then heat up to 800°C at a heating rate of 5°C / min for reaction, and the holding time is 10h; after the reaction, cool to room temperature. The product was successively soaked in 1M dilute hydrochloric acid for 3 hours, soaked in 10% hydrofluoric acid for half an hour, washed with deionized water and alcohol three times. Then, it was filtered by suction and dried in vacuum at 80° C. to obtain a core-shell silicon / carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com