A lateral trench type insulated gate bipolar transistor and its preparation method

A bipolar transistor and lateral trench technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced on-voltage drop, long off-time, current tailing, etc., to reduce saturation Effects of current density, increased forward blocking voltage, and reduced turn-off loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

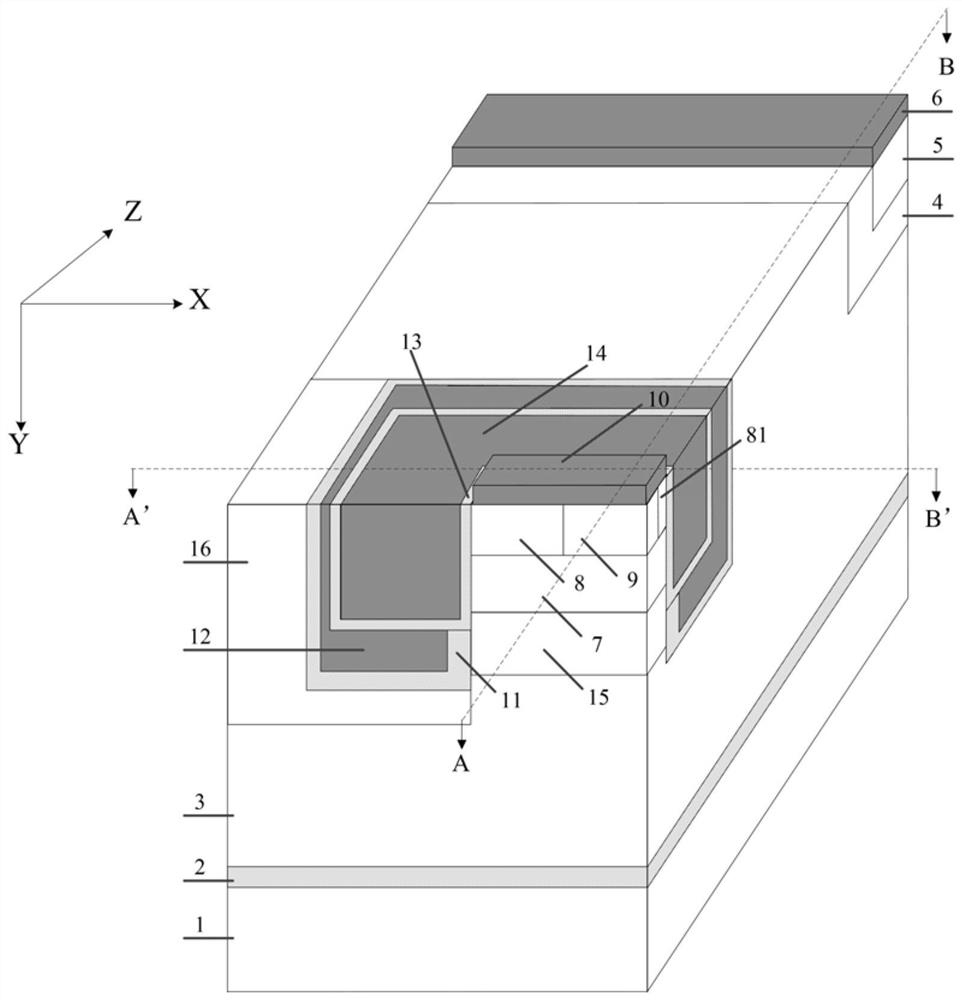

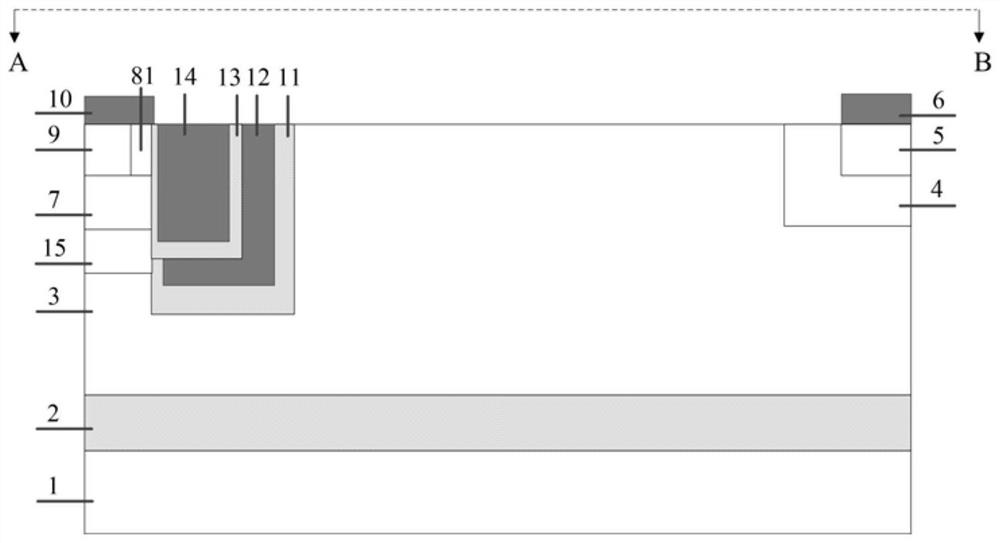

Embodiment 1

[0057] This embodiment provides a lateral insulated gate bipolar transistor, the half-cell structure of which is as follows figure 2 As shown, the two-dimensional cross-sectional structure obtained along the dotted line AB in the semi-cellular structure is as follows image 3 shown. This embodiment includes a P-type substrate 1, a silicon dioxide isolation layer 2, and an N-type drift region 3 arranged in sequence from bottom to top; an N-type buffer zone 4 is arranged on one side of the top layer of the N-type drift region 3 in the longitudinal direction, so The longitudinal direction is the third dimension perpendicular to the horizontal and vertical directions of the device; the N-type buffer zone 4 is provided with an N-type collector region 5, and the upper surface of the N-type collector region 5 is provided with a first metallized collector 6; in the N-type drift region 3, a P-type base region 7 is arranged on the side away from the N-type buffer zone 4 in the longitu...

Embodiment 2

[0066] This embodiment provides a lateral insulated gate bipolar transistor, the half-cell structure of which is as follows Figure 4 shown. In this embodiment, on the basis of Embodiment 1, an N-type doped region 17 is provided on the side of the N-type drift region 3 close to the first silicon dioxide layer 11 in the longitudinal direction, and the doping concentration of the N-type doped region 17 is high. The doping concentration in the N-type drift region 3 ; the vertical depth of the N-type doped region 17 is less than or equal to the vertical depth of the gate oxide layer 11 .

[0067] In particular, the horizontal direction of the N-type doped region 17 can extend from the left border of the half cell to the left border of the gate oxide layer 11 or the right border of the half cell or any position between the two.

[0068] Compared with Embodiment 1, the existence of the N-type doped region 17 can make the drift region in the longitudinal direction of the second emit...

Embodiment 3

[0070] This embodiment provides a lateral insulated gate bipolar transistor, the cell structure of which is as follows Figure 5 As shown, its two-dimensional cross-sectional view along the dotted line CD in the figure is as Figure 6 shown. In this embodiment, on the basis of Embodiment 2, a third metallized emitter 18 is provided above the P-type shielding layer 16 , and the third metallized emitter 18 forms a Schottky contact with the P-type shielding layer 16 .

[0071] In particular, the longitudinal length of the third metallized emitter 18 is smaller than the longitudinal length of the P-type shielding layer 16 .

[0072] Compared with Embodiment 2, the third metallized emitter 18 forms a Schottky contact with the P-type shielding layer 16, and the potential of the P-type shielding layer 16 can be increased during forward conduction, creating a hole barrier to prevent holes from flowing into the P. The type base region 7 can optimize the distribution of carriers in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com