High-strength titanium alloy-graphene composite material and preparation method thereof

A composite material and graphene technology, which is applied in the field of aerospace material preparation, can solve problems such as the uniform mixing of titanium alloy and graphene, the difficulty of graphene's due effect, and the large specific surface area of graphene, etc., to achieve microscopic The effect of uniform structure, high cost performance and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 1998g of pure titanium alloy TC4 powder with a particle size of 150 μm and 2 g of graphene are added into a V-type powder mixer with a rotating speed of 20 r / min and mixed for 24 hours;

[0043] (2) Put the mixed powder obtained from step (1) into a VC high-efficiency mixer, mix for 20min, and rotate at a speed of 100r / min;

[0044] (3) The mixed powder obtained from step (2), balls and 0.1wt% stearic acid are simultaneously placed in a ball mill, filled with liquid nitrogen, and subjected to low-temperature ball milling; wherein, the ball milling speed is 20r / min, and the ball material The ratio (referring to the ratio of the mass of the mixed powder to the mass of the ball) is 25:1, the low temperature ball milling is 2 hours, and the ball milling temperature is controlled at 80K;

[0045] (4) Take out the powder after ball milling and put it into the bag. The material of the bag is No. 20 steel material, the thickness is 2mm, the diameter of the inner cavity is Φ...

Embodiment 2-4

[0050] The titanium alloy-graphene composite material was prepared by the preparation method provided in this application, and the specific preparation process parameters and corresponding properties are shown in Table 1. Except table 1, other processing parameters are identical with embodiment 1.

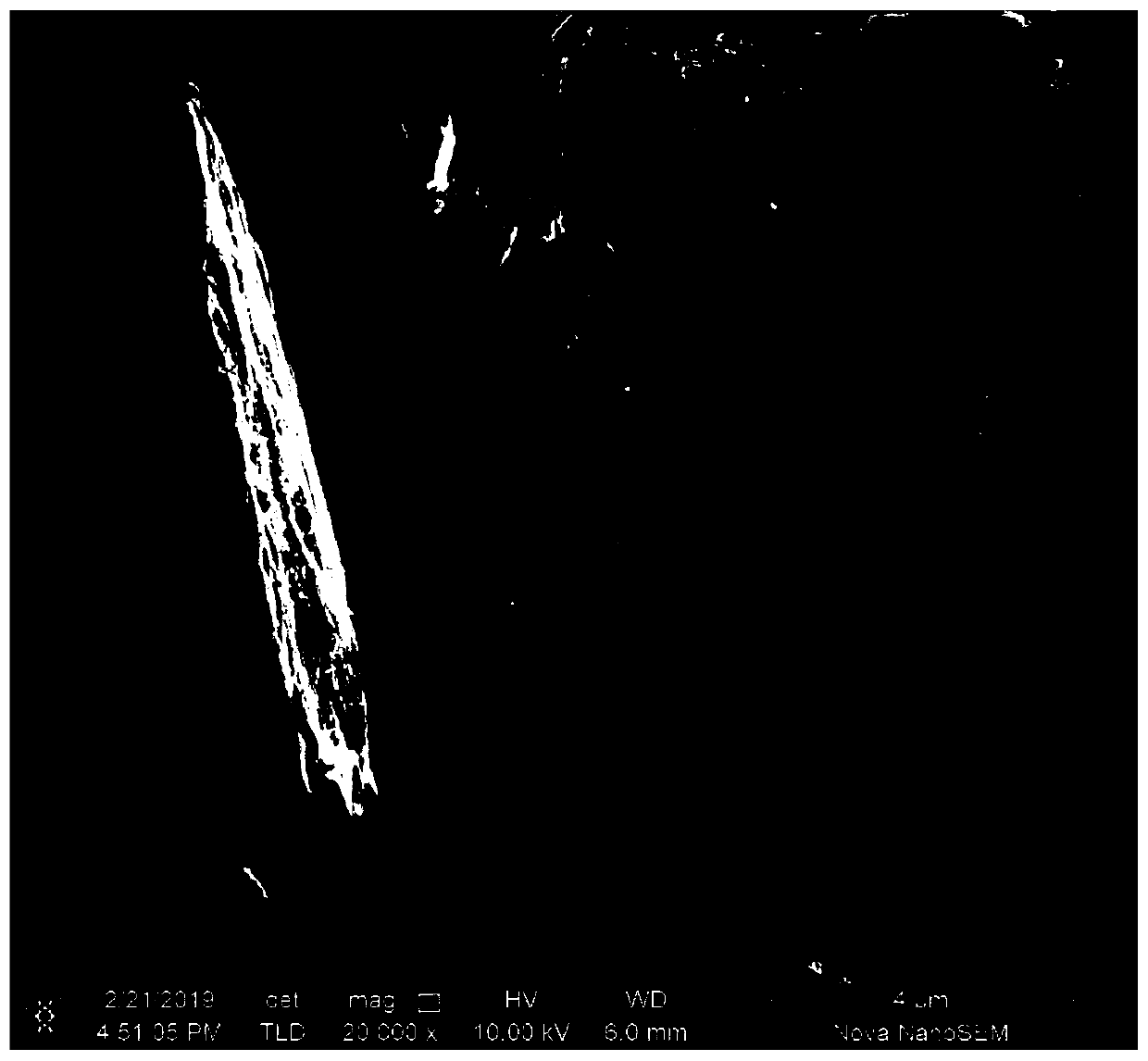

[0051] figure 2 Graphene-coated titanium alloy powder scanning electron micrograph (low magnification) prepared for embodiment 2; image 3 Graphene-coated titanium alloy powder scanning electron micrograph (high power) prepared for embodiment 3; From figure 2 and image 3 It can be seen from the figure that the complete and good coating of titanium alloy powder by graphene can be realized by the preparation method of the present invention. Figure 4 For the high-strength titanium alloy-graphene composite material XRD spectrum that embodiment 2 prepares, show that the high-strength titanium alloy-graphene composite material prepared by the inventive method has no impurity phase...

Embodiment 6-10

[0055] Embodiment 6-10 is compared with embodiment 3 only the ball milling parameter of step (3) is different, and other steps are all identical with embodiment 1. See Table 2 for the low temperature ball milling parameters and product performance parameters of step (3) of this comparative example.

[0056] Table 2 embodiment 6-10 preparation process parameter and corresponding performance

[0057] serial number ball to material ratio Ball milling speedr / min Milling time h Tensile strength MPa Yield strength MPa Example 6 15:1 30 4 985 921 Example 7 20:1 40 5 1010 992 Example 8 60:1 30 4 974 916 Example 9 40:1 48 2 946 884 Example 10 40:1 15 6 968 903

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com